What Makes the 28-inch Wheel Lathe CK6180W Ideal for Wheel CNC Machine Operations?

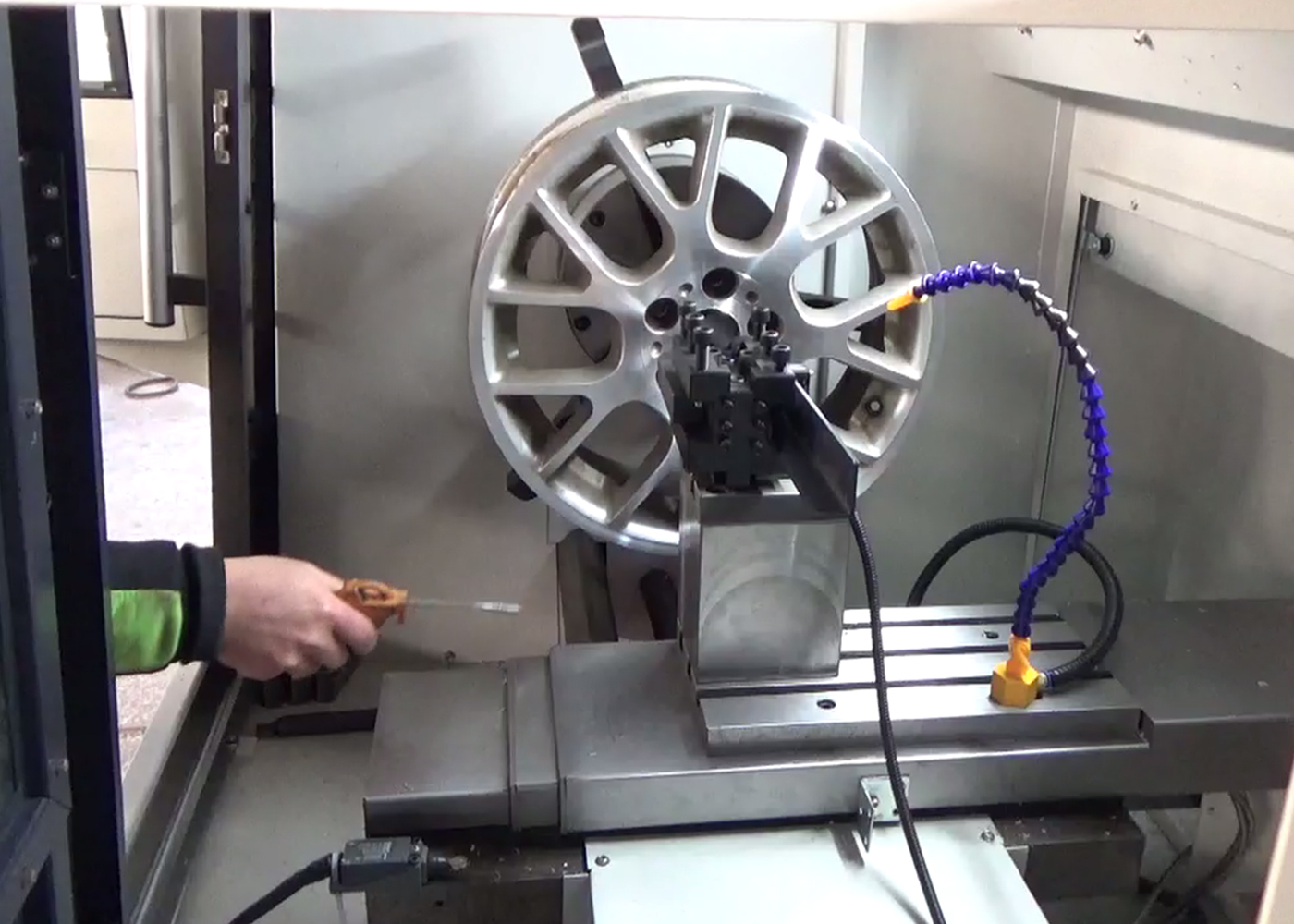

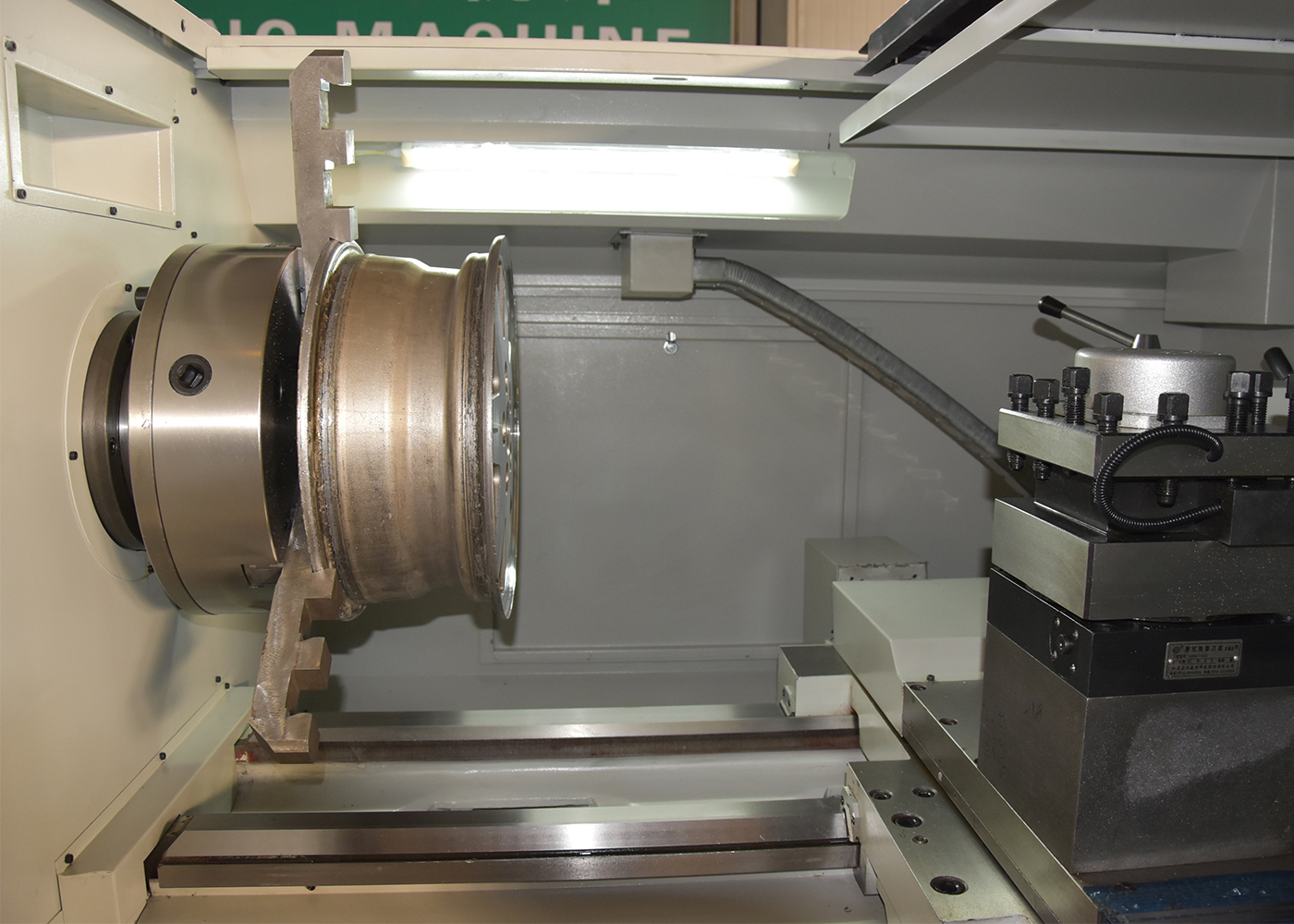

The 28-inch Wheel Lathe CK6180W stands out in the realm of wheel CNC machines due to its precision and cost-effectiveness. Designed with a compact, space-saving frame, it incorporates self-made mechanical parts such as a robust cast steel bed, a reliable spindle, and a sturdy fixing chuck. Its precise feeding mechanism and an imported numerical control system ensure each cut is exact, making it the go-to wheel repair lathe for those who prioritize superb wheel machining and super-finishing.

How Does the 28-inch Wheel Lathe CK6180W Guarantee Precision in Wheel Repair?

Precision in wheel repair is non-negotiable, and the CK6180W wheel repair machine delivers it through its advanced automatic measuring system and high-quality servo motors from renowned brands. Additional features like enhanced lubrication, optimal lighting, and effective cooling mechanisms contribute to its consistent and reliable performance. This synergy of top-tier components and advanced technology makes the CK6180W a leader in its class.

What Customization Options Does the 28-inch Wheel Lathe CK6180W Offer for the UK Market?

Tailored solutions are at the heart of Haishu Machinery’s offerings, particularly evident in the customization options for the CK6180W wheel repair lathe for the UK market. Whether it’s adapting the machine for specific wheel sizes or integrating unique features, the CK6180W can be customized to meet diverse customer needs. Its quality was affirmed by a thorough inspection from the China Certification & Inspection Group (CCIC), ensuring it meets all standards of excellence.

What Advanced Features Does the 28-inch Wheel Lathe CK6180W Include?

The CK6180W is not just about basic functionality; it includes advanced features that enhance its efficiency and user-friendliness. Noteworthy is its automatic laser scanning and quick measurement capabilities, which streamline the machining process by ensuring fast and accurate data handling. Its self-developed CNC software supports automatic program optimization, significantly reducing the time required for wheel processing. Additionally, the machine’s touchscreen interface is designed for ease of use, supporting multiple languages and facilitating diverse machining tasks, including precise diamond cutting for that extra finesse in wheel finishing.

In conclusion, the wheel repair machine CK6180W by Haishu Machinery embodies technical excellence and adaptability. Its state-of-the-art features and ability to deliver high-quality, precise machining make it an indispensable asset for businesses looking to elevate their wheel repair processes. With Haishu Machinery’s commitment to innovation and quality, the CK6180W is poised to meet and exceed global industry expectations.