What Are the Software Advantages of the Economical Wheel Repair Lathe?

The economical wheel repair lathe, specifically the CK6160W model by HAISHU, is renowned for its CNC system that ensures precise control and efficient processing. This lathe is equipped with a user-friendly liquid crystal touchscreen interface, which simplifies operations and enhances adaptability and precision. This feature allows operators to master the lathe quickly, significantly boosting work efficiency. The machine also supports various functions such as turning, grinding, polishing, and drilling, making it a versatile choice for comprehensive wheel repair and machining.

How Does the Economical Wheel Repair Lathe Ensure Effective Wheel Clamping?

The CK6160W wheel repair lathe offers multiple clamping options to cater to different wheel repairs. It includes a three-jaw chuck for stable and balanced clamping, which is ideal for most wheel types. For wheels requiring special handling, a four-jaw chuck or custom-designed fixtures are available. These options provide flexibility in handling wheels with unique designs or those that are irregularly shaped. Additionally, some models may include a hydraulic clamping system, suitable for heavy-duty tasks, although this is less common due to its need for frequent adjustments.

What Key Technologies Are Integrated into the Economical Wheel Repair Lathe?

This wheel repair machine integrates several advanced technologies to enhance its performance. It features an integrated laser probe system that accurately measures the wheel’s profile and geometric parameters, essential for precise machining. The lathe is also equipped with diamond-cutting tools known for their hardness and durability, making them ideal for various wheel materials and repair needs. Additionally, a precise servo drive motor ensures accurate control over the spindle and cutting tools, contributing to consistent and high-quality repair results.

How Does the Economical Wheel Repair Lathe Optimize Workflow and Efficiency?

HAISHU’s wheel CNC machine is designed to streamline workflow and enhance operational efficiency. It includes multiple one-touch operation functions that simplify common tasks, reducing time and effort. The machine’s real-time monitoring capabilities through a parameter window allow operators to make adjustments on the fly, ensuring optimal performance. These features, combined with the lathe’s specialized fixtures and precise measurement capabilities, make it a comprehensive solution for efficient and high-quality wheel repair.

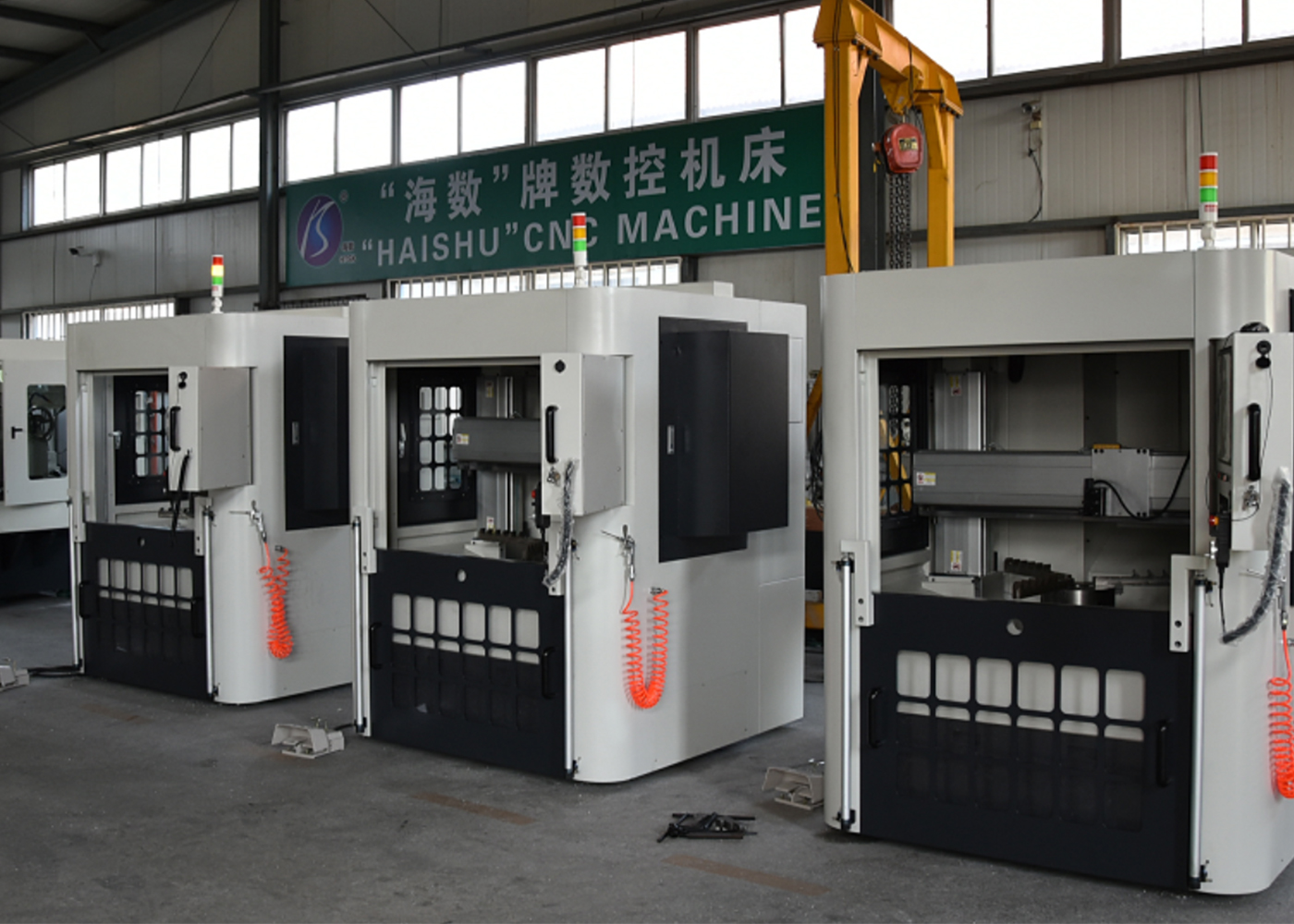

In summary, the vertical wheel repair lathe, particularly the CK6160W model from HAISHU, is a highly capable tool equipped with advanced software and hardware features. Its versatility, precise control mechanisms, and user-friendly interface make it an ideal choice for businesses in the automotive repair industry, looking to enhance their wheel repair and machining capabilities. This machine stands out as a robust solution for handling various wheel types, ensuring precision and efficiency in every task.