Portable wheel repair lathe plays a crucial role in the field of automotive maintenance and machining. wheel repair lathe is a specialized tool used to repair and restore the functionality and performance of wheel hubs. With the ability to be carried in vehicles, this wheel hub repair lathe provides on-site services to customers. This feature is particularly beneficial in countries like Europe and the United States, where customers are geographically dispersed and have a demand for on-site services. By customizing car wheel repair lathes, also known as car-mounted wheel hub repair lathes, we enable our customers to provide services to clients even from a distance.

Here is a detailed overview highlighting the role and importance of portable wheel repair lathe:

Wheel Hub Restoration Capability: A portable wheel repair lathe possesses the ability to grind and restore wheel hubs. They can address surface wear, scratches, dents, and other damages, bringing the wheel hubs back to optimal working conditions. This enhances wheel hub performance and longevity.

Cost Savings: Utilizing a Portable wheel repair lathe for wheel hub maintenance helps avoid the high cost of replacing an entire wheel hub. Repairing wheel hubs is a more cost-effective solution compared to purchasing new ones, especially for cases involving minor surface damage.

Improved Efficiency: Portable wheel repair lathe enable swift wheel hub repairs, saving time and labor. The repair process is typically completed within a short timeframe, allowing vehicles or machinery to resume operation promptly.

Enhanced Safety: Wheel hubs are critical components that bear weight and provide stability in automobiles and machinery. Repairing damaged wheel hubs using a portable lathe ensures structural integrity and performance stability, thereby enhancing driving and operational safety.

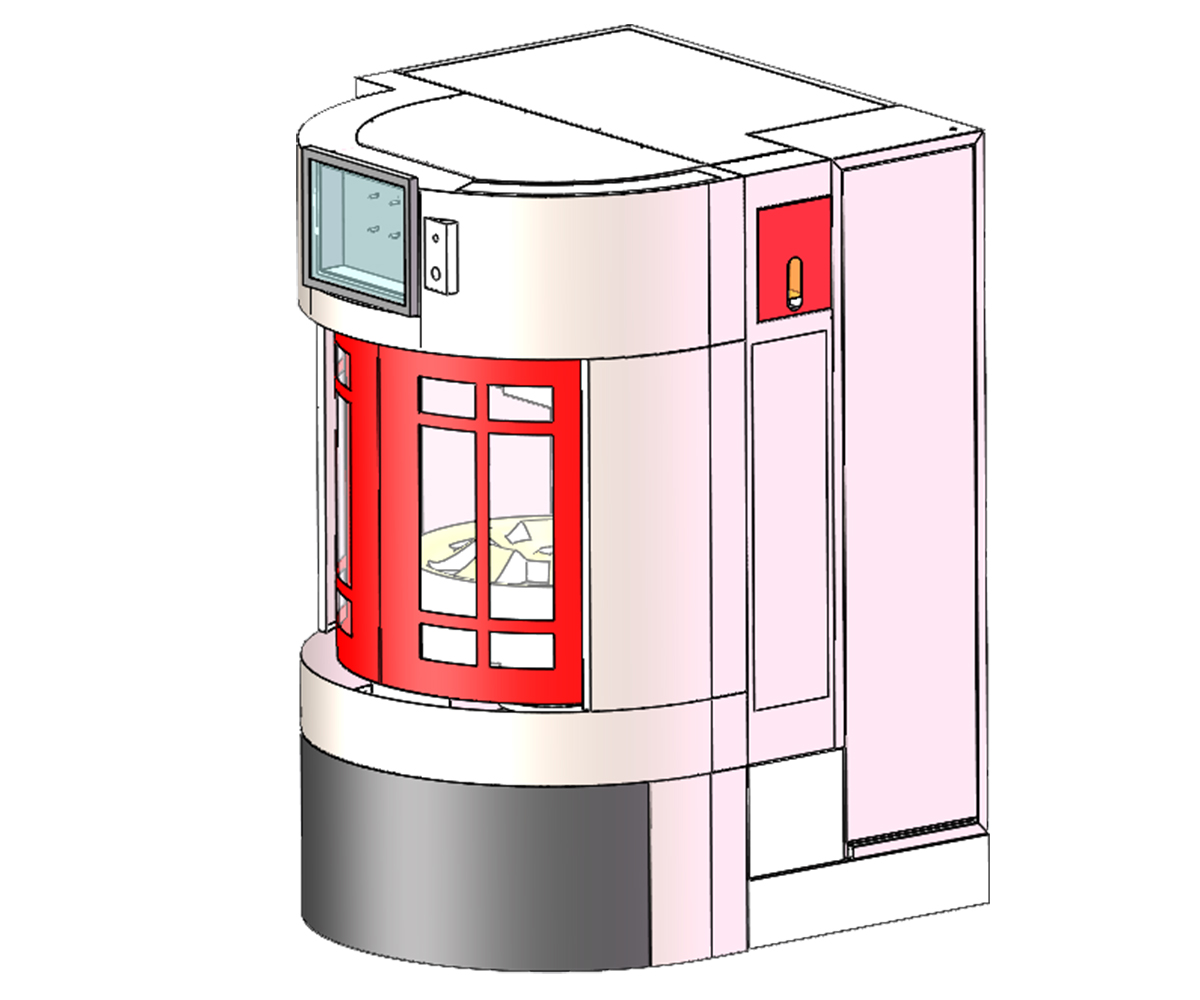

Portability and Flexibility: As the name suggests, portable wheel repair lathes offer ease of mobility and can be easily transported to various work sites. They are typically designed to be compact, facilitating quick installation and operation, making them suitable for a wide range of vehicle and machinery wheel hub repair requirements.

According to statistics, there are over 10 million car accidents occurring worldwide each year. In these accidents, wheel hubs often suffer from impacts, scratches, or deformation. Research indicates that approximately 60% of car accidents involve at least one vehicle with wheel hub damage. Prolonged usage and adverse driving conditions can lead to surface wear and scratches on wheel hubs.

Surveys reveal that over 70% of vehicles have varying degrees of surface wear or scratches on their wheel hubs. During high-speed driving, wheel hubs endure significant forces and vibrations, which can cause structural deformation, surface damage, or even cracks. Studies indicate that prolonged high-speed driving results in visible damage in approximately 30% of wheel hubs.

The global market for wheel hub repair is substantial. Market research forecasts a compound annual growth rate of over 5% in the wheel hub repair market by 2025. This reflects the high demand and market prospects for wheel hub repair services. Thus, the need for portable wheel repair lathe in the automotive repair industry is essential.

Portable wheel repair lathe possess the following characteristics: portability, versatility, flexibility, precision and control, ease of operation, as well as time and cost savings. These features make them efficient, convenient, and cost-effective tools. They are designed to be compact, lightweight, and easy to carry and move. Additionally, they come equipped with various grinding and repair tools to address different types and sizes of wheel hub issues. With high-precision grinding and repair capabilities, they provide a user-friendly interface and control system. Utilizing portable wheel repair lathe enables quick repairs, saving time and labor while avoiding the high cost of replacing entire wheel hubs. In summary, portable wheel repair lathe offer an efficient, convenient, and cost-effective solution for the automotive repair and machining industries.

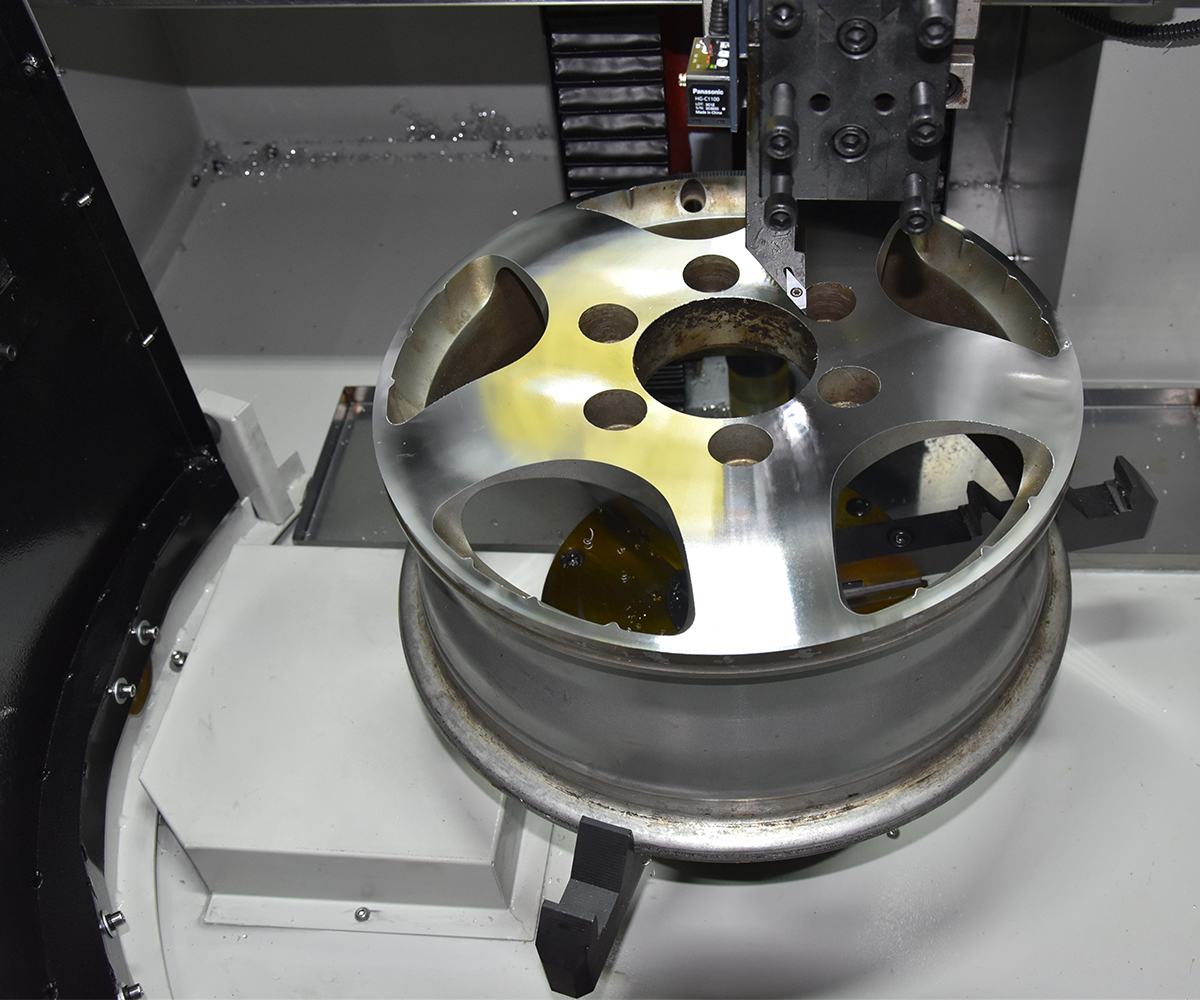

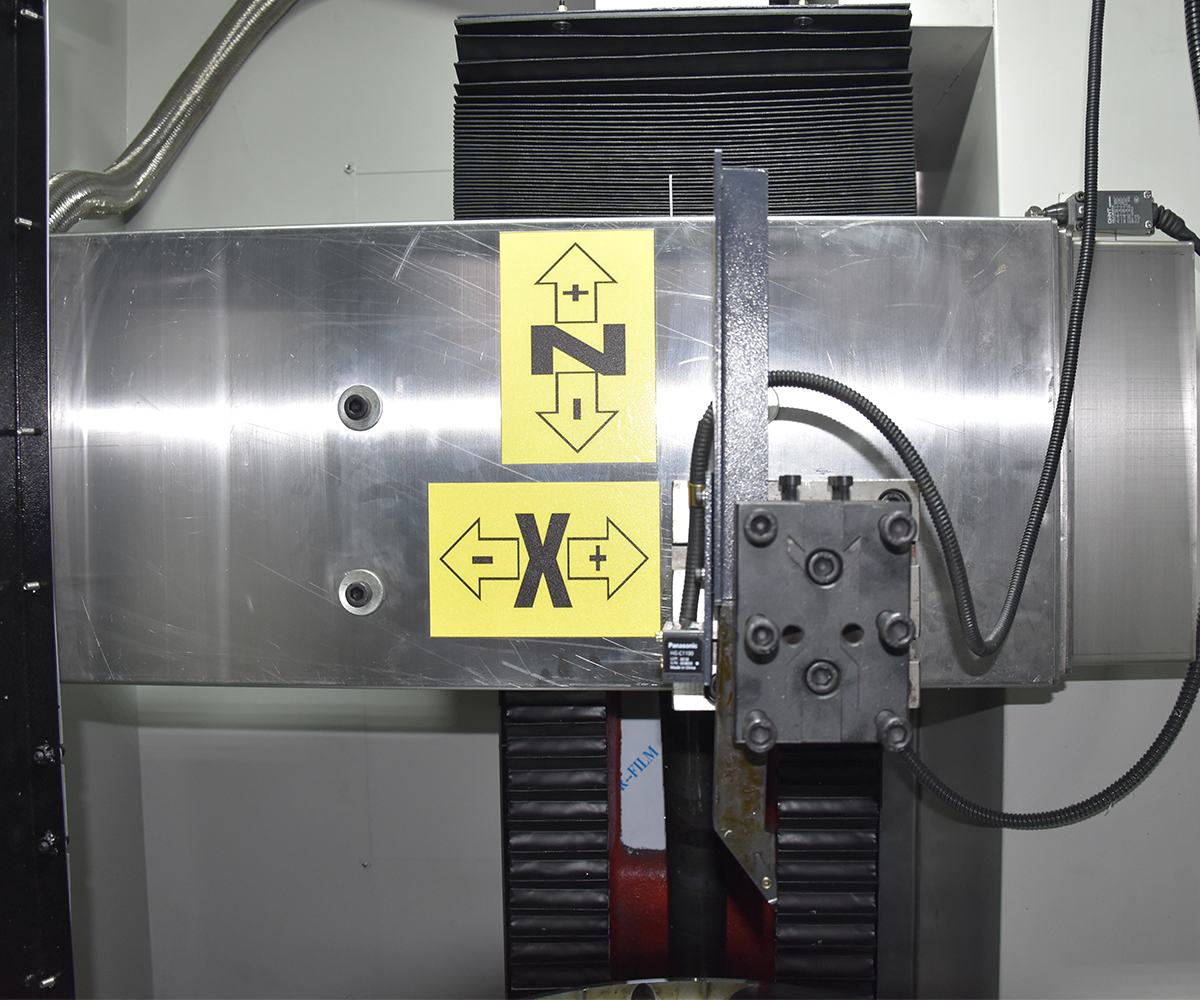

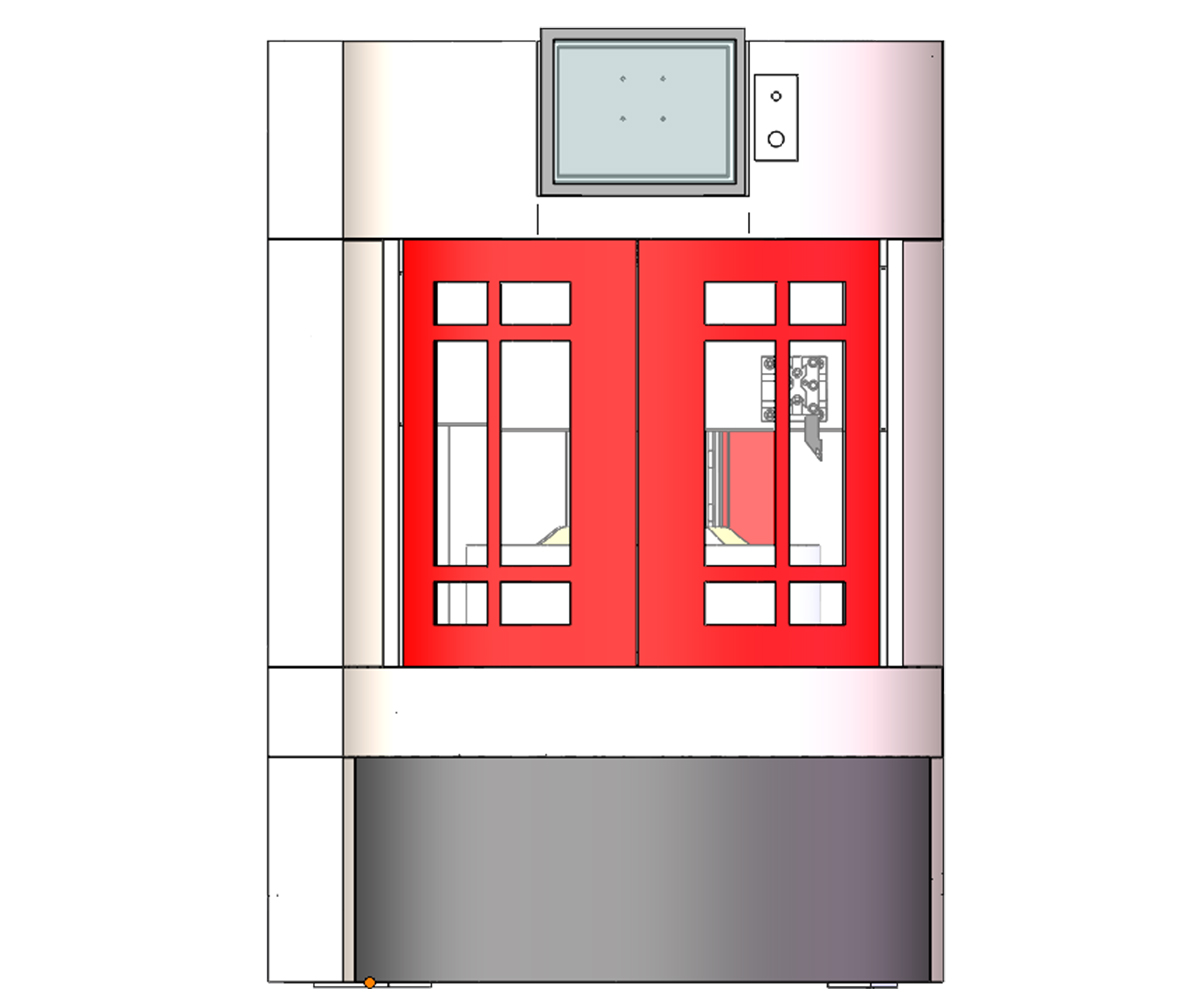

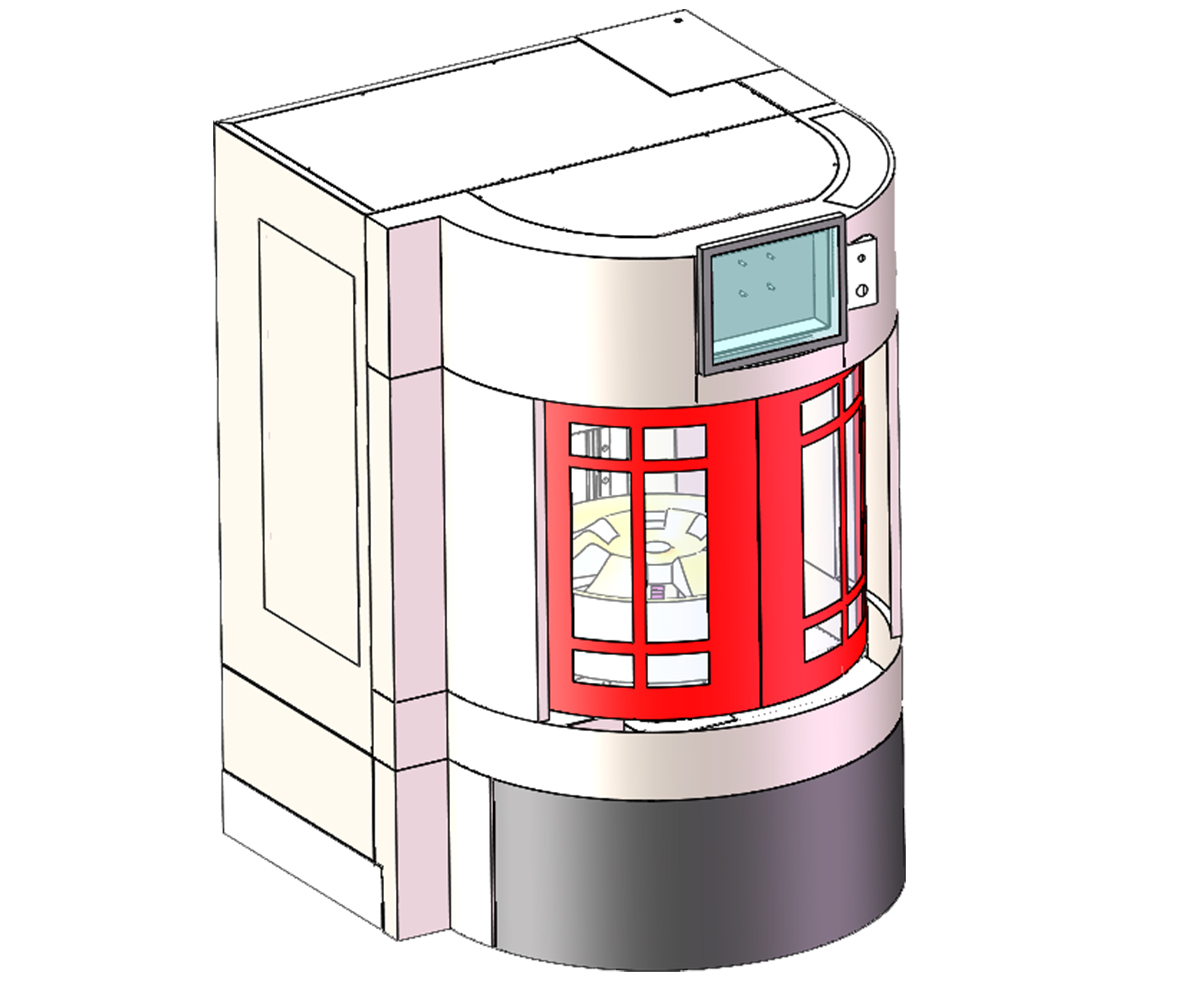

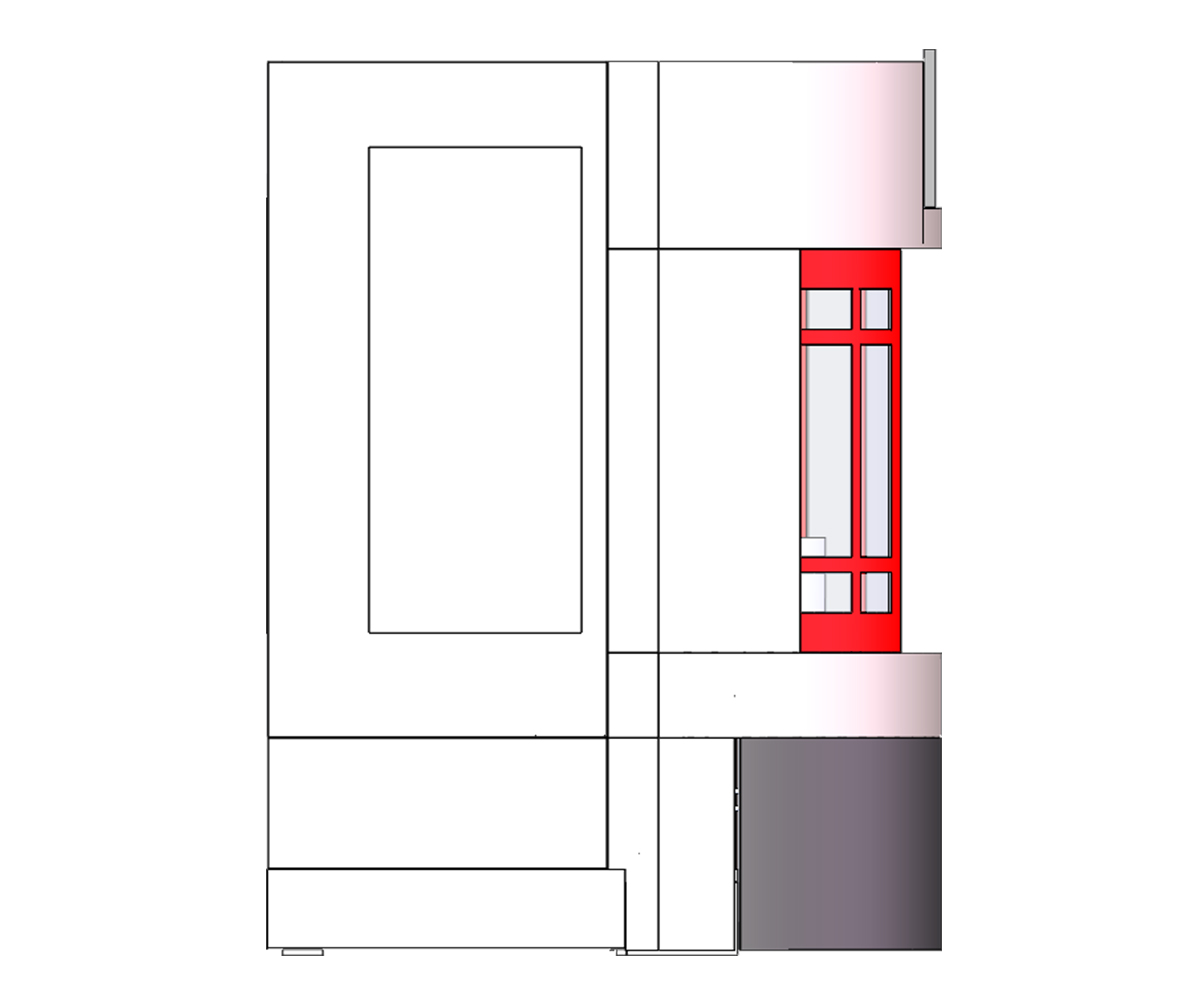

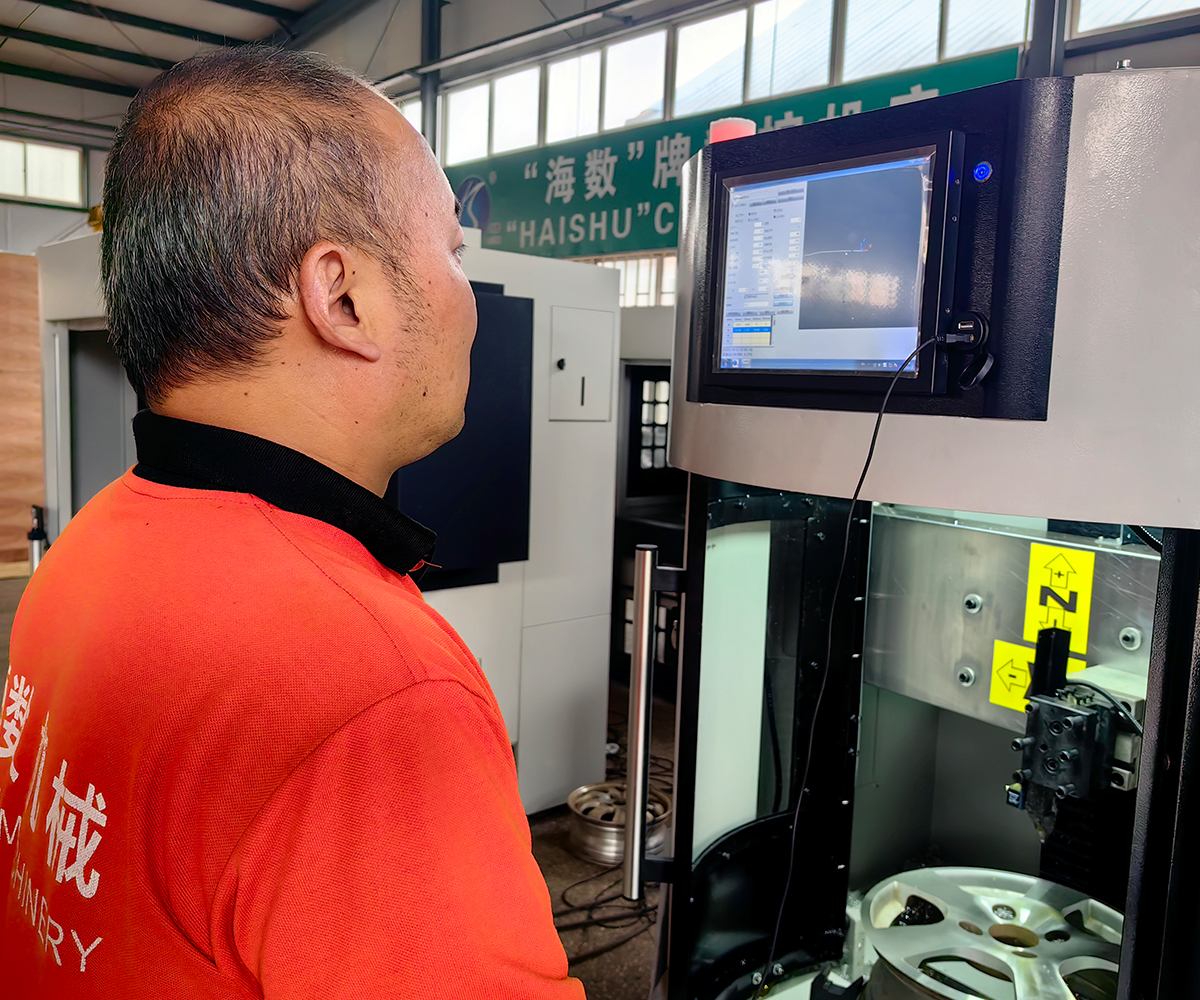

The Portable wheel repair lathe is primarily composed of several key components. The cast iron base is designed to enhance the stability of the lathe, providing support and increased rigidity by lowering its center of gravity. The guide rail section utilizes linear rails to improve mobility speed and machining precision. Additionally, it contributes to achieving a high level of surface smoothness during car wheel hub repairs. To enable precise machining, we have incorporated grinding-grade ball screws, which not only offer high transmission efficiency but also ensure precise and minimal backlash transmission. The control system is the most crucial aspect of the Portable wheel repair lathe. We have designed and developed a system specifically tailored for wheel hub repairs, allowing for simple operation while achieving complex machining tasks. To prioritize customer safety, we have implemented a fully enclosed sheet metal design, enabling customers to operate the wheel hub repair lathe in a secure and comfortable environment.

Here are the general steps for using a Portable wheel repair lathe:

Wheel Hub Mounting: Install the wheel hub that needs repair onto the worktable of the lathe. Ensure the wheel hub is securely clamped in the fixture and adjust the fixture to accommodate the diameter and width of the hub.

Machine Zeroing: Power on the wheel hub repair lathe and perform machine zeroing. This step will bring the machine back to the designated starting position to ensure accurate repair operations.

Laser Automatic Detection: Activate the laser automatic detection function. This feature utilizes lasers to scan the surface of the wheel hub, capturing geometric data and damage information. Through automatic detection, the machine can accurately identify the position and shape of the wheel hub.

Automatic Optimization of Curve Path: Based on the geometric data and damage information of the wheel hub, the repair lathe will automatically generate an optimized curve path. This process considers the shape of the wheel hub, the extent of damage, and repair requirements to ensure precise and efficient repair operations.

One-Click Automatic Tool Alignment: Enable the one-click automatic tool alignment function. This feature automatically adjusts the position and angle of the grinding tool to ensure proper tool alignment and repair operations. The automatic tool alignment function helps avoid human errors and improves repair accuracy.

One-Click Processing: Activate the one-click processing function to initiate the repair operation on the wheel hub. The repair lathe will automatically execute grinding, repair, and processing procedures based on predetermined repair programs and parameters. This step allows for multiple rounds of repair operations based on the specific condition of the wheel hub to achieve the desired repair outcome.

Clean with an Air Gun: After completing the repair, use an air gun to clean the wheel hub, removing any metal shavings and debris generated during the grinding process. This helps maintain the cleanliness of the wheel hub and enhances the visibility of the repair results.

To maintain the optimal condition of portable car wheel hubs, consider the following recommendations:

Lubrication and guide rail maintenance: Regularly inspect the lubrication pump’s oil level to ensure proper functioning. Add lubricating oil as needed. Clean and lubricate the guide rails to ensure smooth operation and extend their lifespan.

Clamping tool maintenance: Periodically check clamping tool tightness. Adjust or replace loose or damaged tools. Maintain clean tool surfaces to ensure secure contact with the wheel hub for precise repairs.

Limit switch maintenance: Regularly inspect and clean limit switches. Ensure correct installation to prevent operational errors or damage.

Tool maintenance: Regularly monitor tool wear. Replace excessively worn or damaged tools promptly. Keep tool surfaces and cutting areas clean for optimal repair quality.

In addition to these specific maintenance tips, general upkeep measures are crucial for portable wheel hub repair. Clean the lathe surface and working area regularly to prevent dust and debris build-up. Inspect power cords and connections periodically. Check and calibrate lathe parameters and control systems for accuracy and stability.

Implementing regular maintenance ensures peak performance and longevity of portable car wheel hubs, delivering high-quality repair services.

Now, let’s discuss a case study on the use of a Portable wheel repair lathe. An automotive repair shop faced the challenge of frequent and time-consuming wheel hub repairs, which were costly for their business. However, they discovered a Portable wheel repair lathe and decided to incorporate it into their repair workflow.

The portability of the lathe proved to be a game-changer for the repair shop. They could now bring the lathe directly to the vehicles in need of repair without having to remove the wheel hubs, saving them considerable time and effort.

During one repair job, a car had noticeable scratches and wear on its wheel hub surface. The repair technicians utilized the Portable wheel repair lathe by clamping the wheel hub and adjusting the lathe to the correct position. They ensured accuracy by using the machine zeroing function.

Next, they utilized the lathe’s laser automatic detection feature. The lathe quickly scanned the wheel hub’s surface, capturing geometry data and damage information. Based on this data, the lathe generated optimized curve paths, ensuring precise and efficient repairs.

With the help of the one-touch automatic tool alignment, the repair technicians adjusted the position and angle of the grinding tool for precise alignment. They then initiated the one-touch processing function, allowing the lathe to automatically perform the grinding and repair process.

Within a few minutes, the scratches and wear on the wheel hub were effectively repaired, restoring its original appearance and performance. The repair technicians used an air gun to clean the wheel hub surface, ensuring it was free of dust after the repair.

This case study exemplifies the powerful capabilities and effectiveness of the Portable wheel repair lathe. By using this lathe, the automotive repair shop improved repair efficiency, saving time and labor costs, while also reducing maintenance expenses. They can now conduct wheel hub repairs quickly and accurately, delivering high-quality service, meeting customer needs, and enhancing their competitiveness.

The Portable wheel repair lathe is a highly versatile and valuable technological tool with numerous applications. It offers substantial benefits to the automotive repair industry, improving repair efficiency and reducing costs. This equipment provides advantages such as the ability to perform repairs directly beside the vehicle, minimizing disassembly and installation time. It delivers precise repair paths, ensuring effective repairs. Additionally, its portability and user-friendly operation enable repair technicians to conduct repairs quickly, delivering high-quality service. The Portable wheel repair lathe is suitable for various vehicle types and wheel hub sizes, providing repair shops with a fast, accurate, and efficient solution for wheel hub repairs. It enhances competitiveness and meets customer demands.