1.Importance and Application Fields of Wheel repair lathe:

Importance: Wheel repair lathe play a crucial role in prolonging the lifespan of wheel rims, enhancing vehicle performance and safety, and saving maintenance costs. They benefit car owners and enable users of wheel repair lathe to provide efficient services to their customers.

Application Fields: Wheel repair lathe are widely used in automobile maintenance, tire services, logistics and transportation, racing, and performance modification industries. By repairing and machining wheel rims, these machines ensure the proper functioning of vehicles and deliver high-quality services. Now, how should we choose between horizontal and vertical wheel repair lathe?

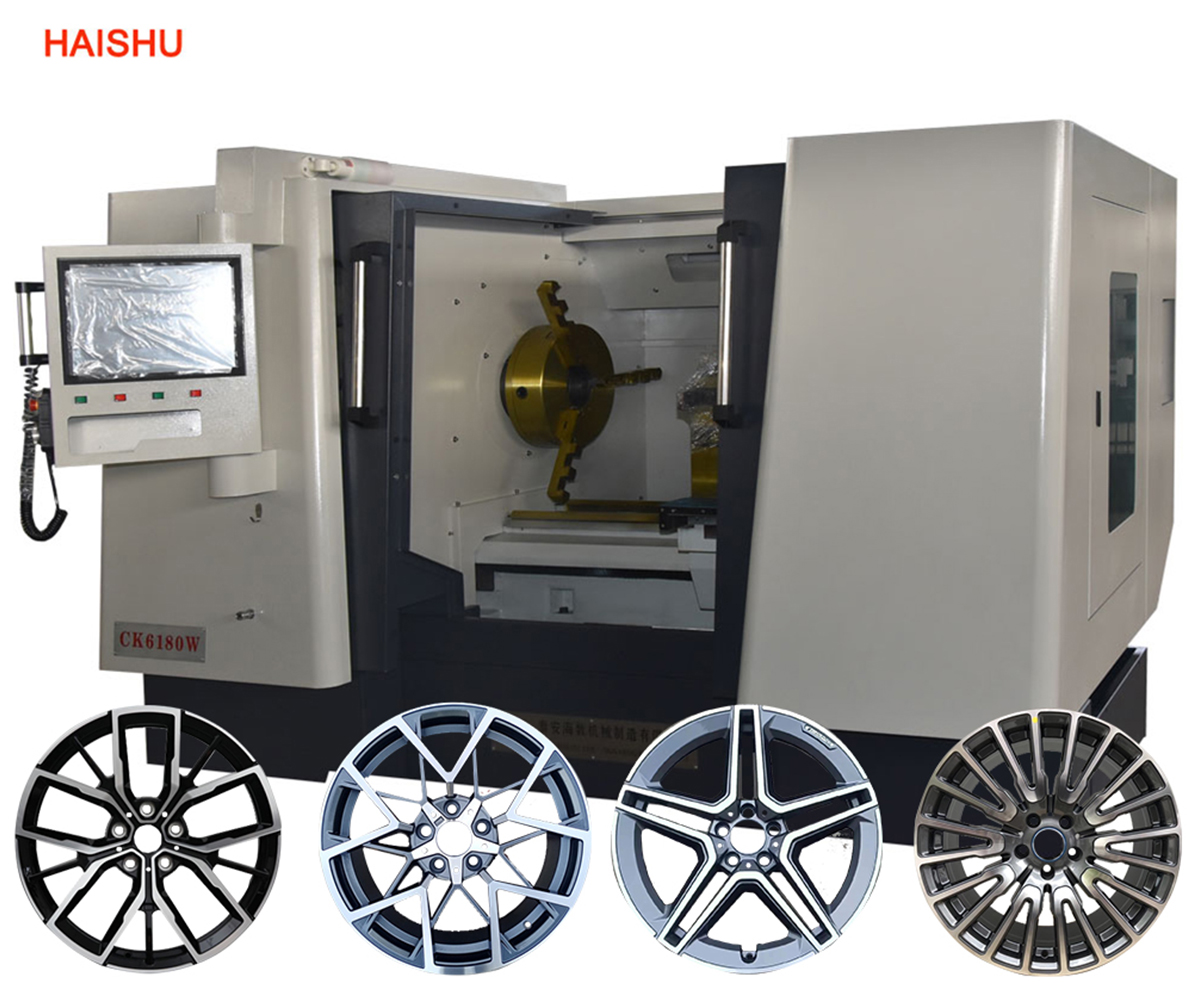

Haisu is a professional company specializing in the design, production, sales, and servicing of wheel repair lathe. Currently, our wheel rim repair machine products are sold in over 90 countries and regions worldwide, with authorized distributors in certain areas such as the European Union, Southeast Asia, North America, and more.

2. Horizontal Wheel repair lathe

2.1 Working Principle of Wheel repair lathe:

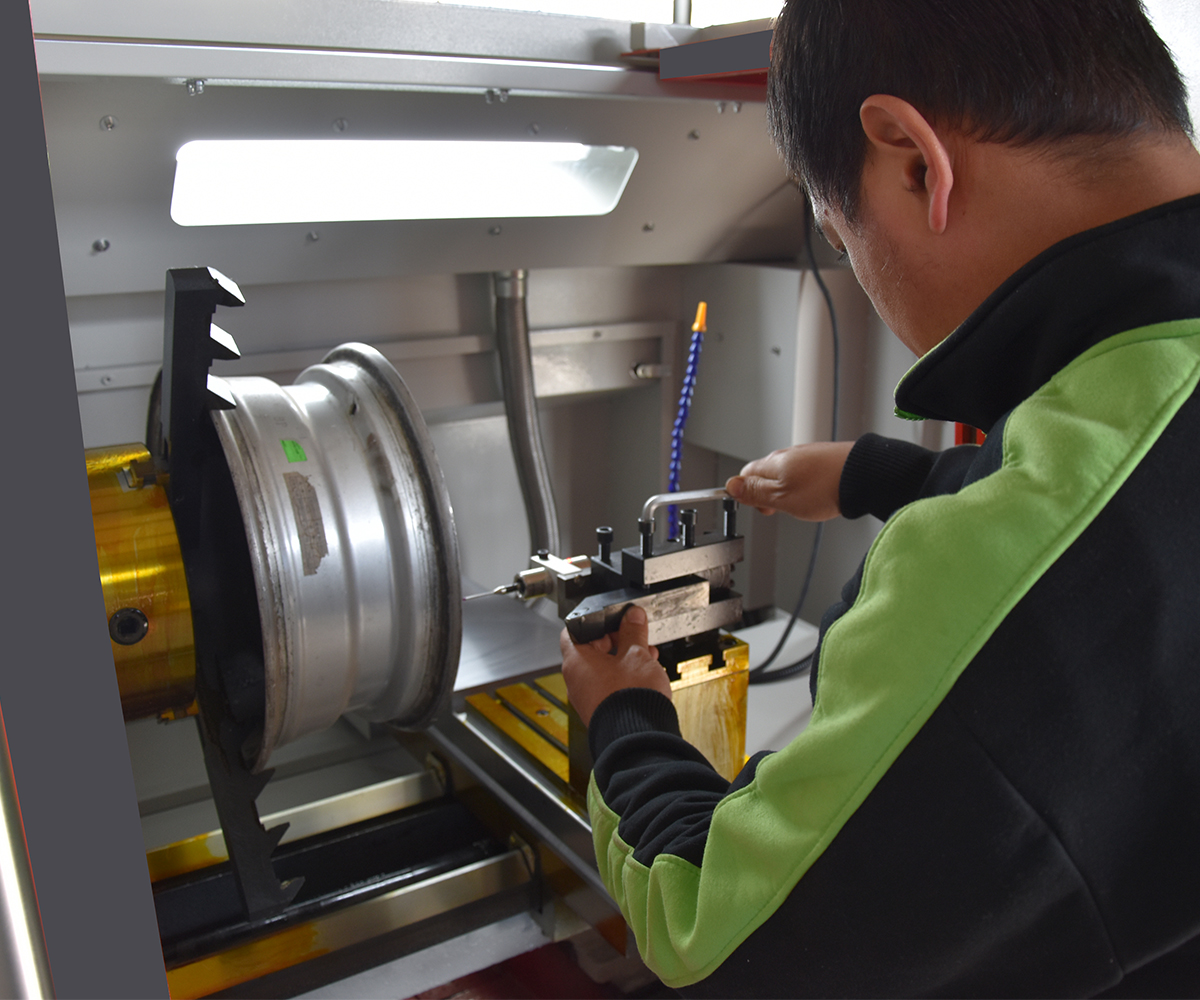

The working principle of a horizontal wheel rim repair machine is relatively simple. The wheel rim is clamped vertically onto a chuck or custom fixture. Prior to this, the wheel rim is cleaned and inspected for any deformations. If deformations are detected, they are rectified using a wheel rim reshaping machine. The machine then utilizes laser detection to analyze the wheel rim’s surface and generates a processing path through specialized algorithms for wheel rim cutting. Finally, the wheel rim undergoes paint spraying treatment.

2.2 Advantages of Horizontal Wheel repair lathe:

Economic Efficiency: Horizontal wheel repair lathes are based on horizontal CNC lathes, which simplifies their design, processing, and assembly. Consequently, the cost is relatively low. Therefore, they are suitable for users facing economic pressures.

Automation Capability: The machine incorporates automated detection and optimization processes, enabling operators to quickly grasp the operational steps.

High Precision Repair: With CNC programming after data collection, the machine allows for precise control during processing.

In addition to the aforementioned features, Haishu’s horizontal wheel repair lathe is equipped with three types of detection functionalities: laser detection, probe detection, and tooltip detection. This allows users to choose the appropriate wheel rim detection method based on their specific requirements.

3. Vertical Wheel repair lathe

3.1 Workflow of Vertical Wheel Rim Repair Machines

principle of vertical wheel repair lathe is similar to that of horizontal ones. Before the repair process, the wheel rims are inspected for deformations and then thoroughly cleaned. The wheel rims are clamped horizontally and undergo automatic laser detection and optimization programs before the automated machining process begins.

Vertical wheel repair lathe are further categorized into double-column and single-column structures, designed to repair different sizes of car wheel rims.

3.2 Advantages of Vertical Wheel repair lathe

3.2.1 Versatility: Vertical wheel repair lathe can accommodate various wheel sizes, making them suitable for processing different-sized wheel rims. They offer a high level of versatility.

3.2.2 Space Efficiency: The vertical structure allows for placement in narrow spaces, such as small workshops or inside vehicles. These machines occupy a smaller footprint, freeing up more space for other equipment.

3.2.3 High Configuration: Vertical wheel repair lathe often utilize linear guides for precise and smooth surface machining of car wheel rims.

High Automation Level: Vertical structures are equipped with higher levels of automation, including automatic doors, safety gates, and one-touch detection functions.

Efficiency: Vertical wheel repair lathe are specially designed for car wheel rims, resulting in processing efficiency that can be double or even higher than that of horizontal structures.

3.2.4 Ease of Maintenance: The vertical structure employs a linear guide mode, allowing for simple and quick replacement during maintenance and repairs.

HAISHU offers both double-column and single-column vertical wheel repair lathe. The double-column, also known as a gantry structure, provides efficient and automated processing for large wheel rims. The single-column wheel rim repair machine is particularly suitable for small spaces, such as storefronts or trucks. These machines offer fully automated operations, including one-touch detection, optimization, tool alignment, and machining functions.

4. Comparison and Contrast of Horizontal and Vertical Wheel repair lathe

4.1 Performance Comparison: The vertical wheel rim repair machine offers higher precision compared to the horizontal structure, as it utilizes linear guides, which is the most powerful configuration for alloy car wheel rims. Additionally, the vertical structure provides better processing efficiency and reliability in comparison.

4.2 Scope of Application Comparison: The vertical wheel rim repair machine can handle larger-sized car wheel rims. In the case of horizontal structures, larger wheel rims can generate more centrifugal force, leading to machine vibrations. The horizontal structure is more suitable for smaller wheel types and vehicle models.

4.3 Cost Comparison: The vertical wheel rim repair machine is equipped with linear guides, spindle units, and various servo motors, resulting in higher costs. On the other hand, the horizontal structure uses rigid guides instead of linear guides, which makes it more cost-effective. However, in terms of maintenance costs, the vertical structure with linear guides allows for direct replacement, ensuring the machine maintains the quality standards of a new one, thus resulting in lower overall maintenance costs.

HAISHU offers both horizontal and vertical wheel repair lathe, allowing users to choose the appropriate structure based on their specific needs.

5. Conclusion

Users can choose the appropriate wheel rim repair machine based on the wheel rim sizes commonly encountered in their shop or repair company. If the majority of the wheel rims are 24 inches or larger, the vertical structure machine should be prioritized. On the other hand, if the wheel rim sizes are mainly 22 inches or smaller, the horizontal structure machine can be considered.

Furthermore, the choice of machine should also take into account space limitations. If the shop is small or if there is a need to place the machine inside a truck, the vertical structure is the best option. However, if there is a large workshop available, space constraints may not be a major concern.

Additionally, it is recommended to consult friends or companies who have experience using wheel repair lathe to gather more advice. Taking into consideration one’s own practical circumstances, the purchase and selection can be made accordingly.

HAISHU is a professional manufacturer of wheel repair lathe, providing efficient and professional consulting services to customers. We offer tailored services such as logo customization, voltage configuration, and supporting equipment. If you have any needs, please feel free to contact us.