What is a Top Wheel Refurbishment Lathe?

The development of top wheel refurbishment lathes has a long history. From the initial simple use of polishing wheels for repair to the current use of specialized PCD (polycrystalline diamond) tools for machining, there have been significant improvements in efficiency and quality. In this article, we will explore how top wheel refurbishment lathes have evolved and why they are crucial in the industry today.

How Did the Top Wheel Refurbishment Lathe Evolve?

Initially, car wheels were made of steel. When they became worn, simple grinding and painting could refurbish them. However, with the advancement of automotive technology, wheels are now made of aluminum alloy. When these wheels become worn, traditional refurbishment techniques are no longer sufficient. This led to the development of new wheel CNC machines, specifically designed for alloy wheel repair.

These new machines are based on traditional CNC lathes but with increased spindle height to accommodate the rotation of larger wheels. However, traditional CNC lathes are slow and cannot perform automatic detection. Operators had to manually record each point and input them into the system to create a machining program, which required skilled alignment techniques. This method placed high demands on the operator’s technical abilities. The need for a simpler and more efficient wheel repair machine led to the development of advanced top wheel refurbishment lathes.

What Are the Key Features of a Top Wheel Refurbishment Lathe?

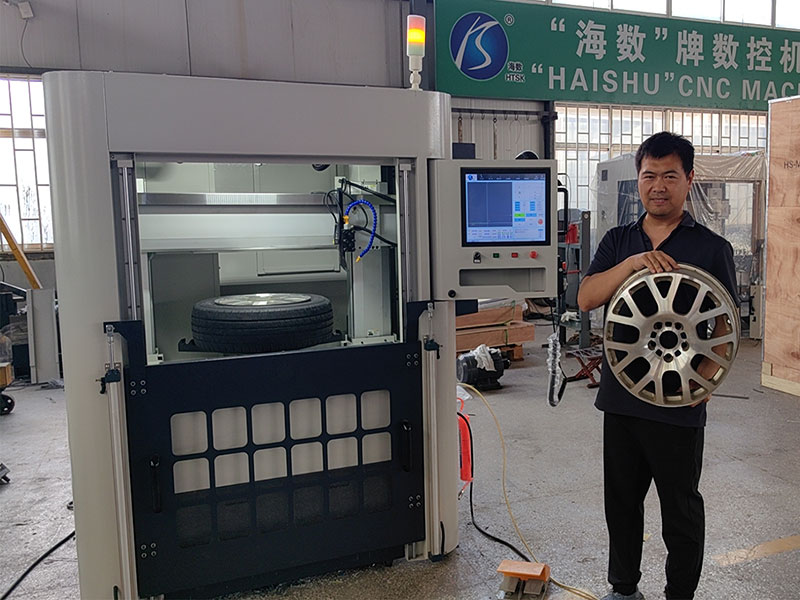

To cater to smaller wheels, Taian HAISHU designed six models of horizontal wheel lathes. These are not only easy to operate but also cost-effective, achieving a high cost-performance ratio. However, this article will focus on our vertical wheel repair lathes, also known as mobile wheel repair lathes.

Our vertical wheel repair machines feature a double-column gantry structure, which increases rigidity and extends the range of movement, making them ideal for large car wheels. Additionally, specially designed extended fixtures enable quick clamping, saving a significant amount of time.

For efficient detection, we developed precise laser detection technology. Laser detection does not require contact with the wheel surface, preventing collisions and completing detection in just 15 seconds. We also have contact-type probes, though these take longer for detection. Once detection is complete, our system directly transitions to the curve optimization phase, eliminating the need to export curves for external optimization and re-import them into the system. The HAISHU system can optimize curves internally, fully automating the process. We also offer one-click programming, eliminating the need for manual programming, and one-click alignment, requiring zero CNC knowledge from the operator, who can master the system in just 30 minutes.

Why Choose a Top Wheel Refurbishment Lathe from HAISHU?

HAISHU’s top wheel refurbishment lathes support various customizations, such as logo customization, which allows customers to integrate their brand into the system. We can also tailor the voltage to 110V, 220V, 380V, or 415V. If there are language requirements, we offer various language customizations, making our machines suitable for your ODM (Original Design Manufacturer) needs.

How Does a Top Wheel Refurbishment Lathe Improve Efficiency?

The top wheel refurbishment lathe is designed to streamline the wheel refurbishment process significantly. Traditional methods required manual input and skilled labor to create precise machining programs. Our machines, however, utilize advanced technology such as laser detection and automated programming to reduce the time and expertise needed. This not only speeds up the process but also improves the accuracy and quality of the refurbishment.

What Makes HAISHU’s Top Wheel Refurbishment Lathe Stand Out?

HAISHU’s top wheel refurbishment lathes are equipped with state-of-the-art features that make them stand out in the market. The double-column gantry structure provides unmatched rigidity and stability, which is crucial for handling large wheels. The laser detection system ensures precise measurements without the risk of damaging the wheel surface. Additionally, our machines offer quick clamping and easy operation, making them user-friendly and highly efficient.

Can a Top Wheel Refurbishment Lathe Handle Different Types of Wheels?

Yes, a top wheel refurbishment lathe from HAISHU can handle various types of wheels, including alloy wheels. The machines are versatile and can be customized to fit different wheel sizes and materials. This makes them an excellent choice for workshops that deal with a variety of wheel types.

What Customization Options Are Available for a Top Wheel Refurbishment Lathe?

HAISHU offers a range of customization options for their top wheel refurbishment lathes. Customers can choose to have their brand logo integrated into the system, tailor the machine’s voltage to suit their country’s requirements, and select from various language options. This level of customization ensures that the machine meets the specific needs of each customer, making it an ideal solution for global markets.

How Can a Top Wheel Refurbishment Lathe Benefit Your Business?

Investing in a top wheel refurbishment lathe can significantly benefit your business by increasing efficiency, reducing labor costs, and improving the quality of your wheel refurbishments. The advanced features of HAISHU’s machines ensure that you can deliver high-quality results consistently, which can enhance your reputation and attract more customers. Additionally, the ability to customize the machine to your specific needs ensures that you get the best possible return on your investment.

Conclusion

The top wheel refurbishment lathe is an essential tool for modern automotive workshops. Its advanced features and customizable options make it a versatile and efficient solution for refurbishing wheels. By investing in a high-quality wheel repair machine from HAISHU, you can improve your operational efficiency, reduce costs, and deliver superior results to your customers. Whether you are dealing with alloy wheels or other types of wheels, HAISHU’s top wheel refurbishment lathe is the ideal choice for your business needs. We invite you to visit our company or send a representative to see our machines in action and discover how they can benefit your operations.