1. What Are the Key Features of a Rim Straightening Machine for Sale?

1.1 Understanding the Basic Design

When considering a rim straightening machine for sale, the appearance and design are crucial factors for potential buyers. However, many customers may lack prior experience with such machines, making it difficult to understand their configurations. This article will introduce the rim straightening machine from Tai’an Haishu, helping you identify the right wheel repair machine(tekerlek tamir makinesi) for your needs while ensuring the best cost-performance ratio.

1.2 Basic Components of the Machine

The most fundamental wheel repair lathe (مخرطة إصلاح العجلات)for reshaping wheels features a hydraulic reshaping function. Its main components include:

- Spindle: The spindle provides rotational movement. It must be fitted with an alignment pin before reshaping to identify deformed areas on the car wheel hub.

- Crab Claws: These are essential for supporting the wheel hub during the reshaping process.

- Hydraulic Jack: Used to apply force for reshaping the wheel hub.

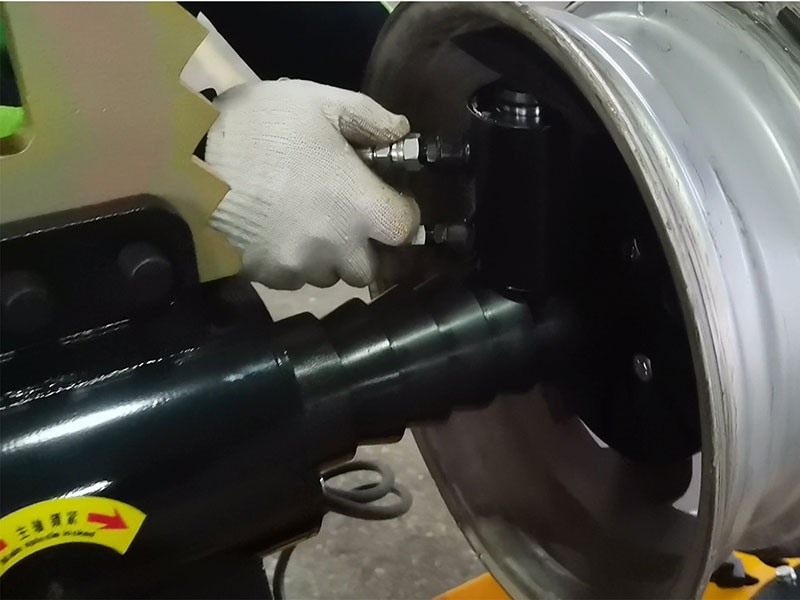

- Chuck: The chuck on the spindle secures the wheel hub in place.

Before starting the reshaping process, the car wheel hub is mounted on a specialized chuck equipped with various mounting slots suitable for 99% of car wheel hub sizes. Special screws are used to firmly secure the wheel hub onto the machine, allowing for quick alignment and installation.

2. How Does the Rim Straightening Machine for Sale Operate?

2.1 The Reshaping Process

The operation of a rim straightening machine for sale begins with mounting the deformed wheel hub onto the specialized chuck. The spindle is then rotated to identify the deformed areas, which are marked with chalk. A heat gun is utilized for heating the wheel hub, softening the material for easier reshaping. After the wheel hub is adequately heated, the hydraulic jack is engaged to perform the correction.

2.2 Importance of Crab Claws and Hydraulic Support

The crab claws play a vital role in supporting the wheel hub during the vertical installation. They work in conjunction with the hydraulic jack to provide the necessary support from various angles, ensuring effective reshaping. The unique design of the crab claws, along with extended rods provided with the hydraulic jack, allows for versatile reshaping options, accommodating different wheel hub configurations.

3. What Advanced Features Are Available in a Rim Straightening Machine for Sale?

3.1 Turning Function for Enhanced Repair

Some rim straightening machines for sale come with an additional turning function. This feature is critical for car wheel hubs that may suffer from cracks or missing parts. In such cases, an aluminum welding machine is used for repairs. After welding, excess material must be ground down and cut off for a smooth finish.

3.2 Upgraded Cutting Tools

Previously, cutting tools used for this process were welded tips, which proved to be less durable and had weak impact resistance. Now, Tai’an Haishu offers specialized diamond and forming tools that can be quickly replaced, significantly reducing machining time. The turning tool holder with this function features scales and can rotate to any angle after loosening the screws. Once the desired angle is set, it is secured, making it easier to address different damaged areas on the wheel hub.

4. What Models of Rim Straightening Machines for Sale Are Available?

4.1 Variety of Models

Tai’an Haishu has developed three models of rim straightening machines, each customized according to different customer needs. These variations include adjustments in voltage, functions, configurations, and branding options. The machines cater to diverse applications, making them suitable for various wheel CNC machines and aluminum wheel CNC lathe needs.

4.2 Customization and Branding Options

In addition to standard features, Tai’an Haishu offers ODM branding services, allowing customers to personalize their machines. This ensures that businesses can maintain their brand identity while benefiting from high-quality machinery. If you require more specific product details and configurations, please don’t hesitate to contact us.

5. What Is the Rim Straightening Machine Price and Its Value?

5.1 Cost Considerations

When purchasing a rim straightening machine for sale, the price is always a key consideration. The cost can vary based on features, functions, and customization options. Generally, investing in a quality rim straightening machine can yield significant returns in terms of efficiency and service quality.

5.2 Value for Money

While the initial investment may seem high, the long-term benefits of owning a reliable wheel repair machine (machine de réparation de roues) are substantial. With efficient operations, lower maintenance costs, and enhanced customer satisfaction, the rim straightening machine price (Radreparaturmaschine) reflects its value in the market.

6. Conclusion: Finding the Right Rim Straightening Machine for Sale

In summary, understanding what a rim straightening machine for sale looks like and how it operates is essential for making an informed purchase. By considering the design, features, and pricing, you can choose the best machine to meet your needs. For more information or to explore our range of machines, please contact Tai’an Haishu. With numerous distributors and service providers worldwide, we’re here to help you enhance your wheel repair capabilities.