1. What Is an Alloy Refurb Machine?

An alloy refurb machine is specifically engineered to repair scratches, dents, and other damages on the surface of car rims. These damages can result from scraping, collisions, or general wear and tear. By refurbishing the rims to a condition that meets factory specifications, these machines help maintain the value of used or accident-damaged vehicles. This is particularly beneficial for car owners and second-hand car dealers, as it reduces economic losses. In this article, we will explore the features and benefits of alloy refurb machines, particularly those from Taian Haishu Company.

2. How Does an Alloy Refurb Machine Work?

2.1 Core Components of the Alloy Refurb Machine

The heart of a wheel lathe machine(آلة إصلاح العجلات) is its CNC system, also known as the wheel refurbishment system. Taian Haishu has developed a proprietary system that boasts full intellectual property rights. Currently in its sixth generation, this system has undergone numerous upgrades based on feedback from customers in over 100 countries.

2.2 Detection Features

The machine includes several advanced detection capabilities:

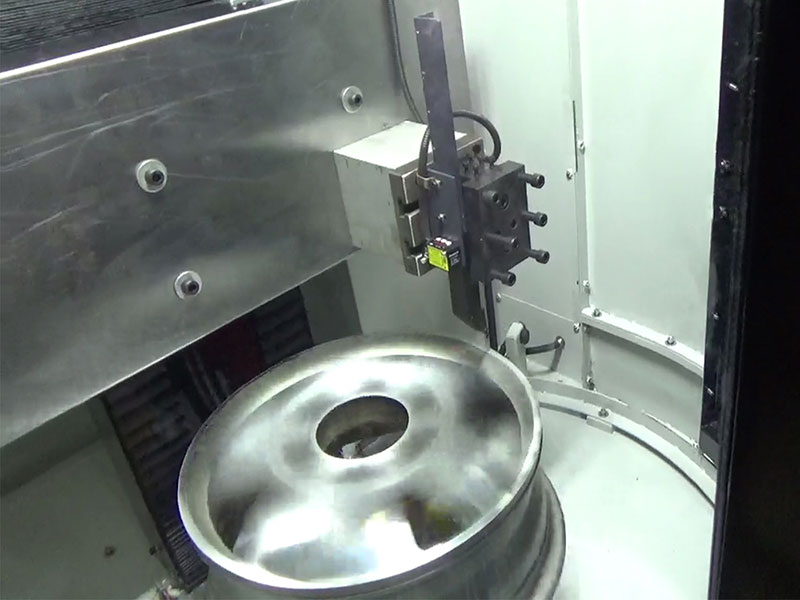

- Laser Detection: A fast method that completes the detection process in just 15 seconds.

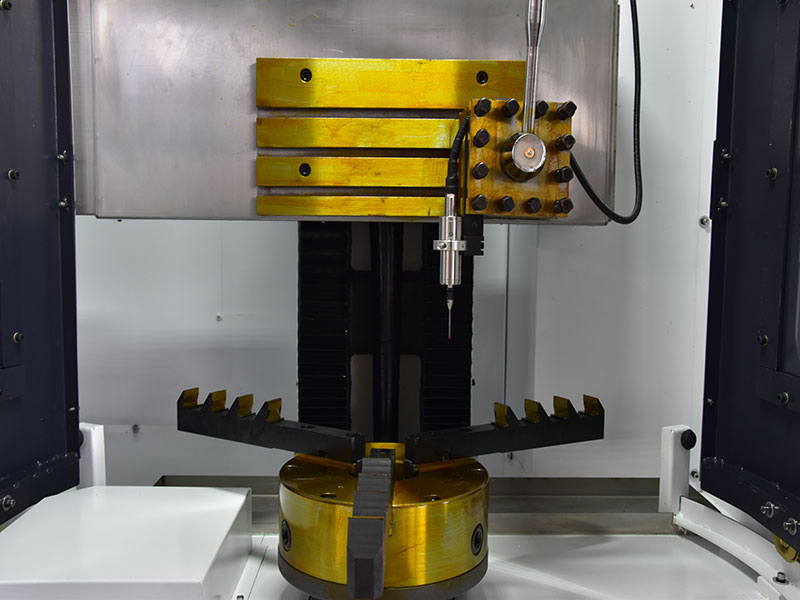

- Probe Detection: Ideal for wheels with significant curvature changes.

- Tool Tip Detection: The most precise but also the most time-consuming method, specifically designed for deep-lip processed wheels.

These detection features allow for both automatic and manual optimization, streamlining the refurbishment process.

3. What Are the Advantages of Using an Alloy Refurb Machine?

3.1 Time Efficiency

One of the standout features of Taian Haishu’s alloy refurb machine is its one-click output of CNC programs. This significantly reduces programming time and lowers the skill threshold required for operators. Beginners can learn to master this system within just 30 minutes, producing programs comparable to those created by experienced technicians.

3.2 Custom Program Naming

The outputted CNC programs can be named according to customer preferences, making it easy to identify which program corresponds to specific types of car rims. This facilitates future use for similar rims, saving time on detection and optimization.

4. What Are the Key Features of Taian Haishu’s Alloy Refurb Machine?

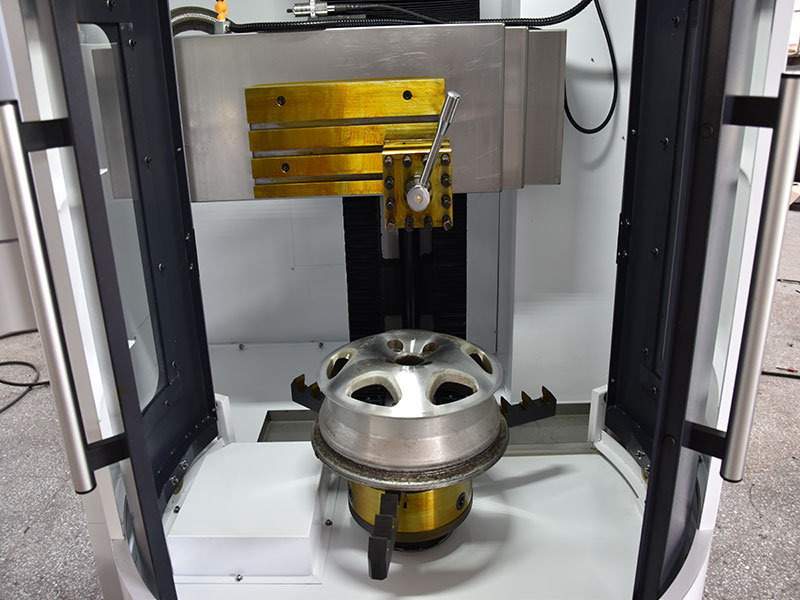

4.1 Specialized Chuck Furniture

The wheel repair machine(Máquina de reparo de rodas) features a specialized three-jaw extended jaw chuck, allowing for quick and efficient clamping of rims. This design improves the overall workflow, making it easier to switch between different rim sizes.

4.2 Tool Holder Options

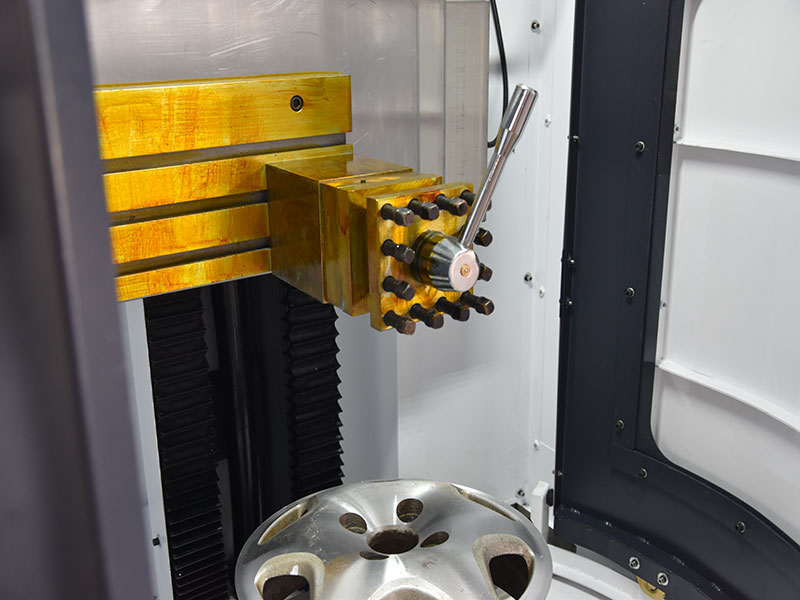

Taian Haishu provides a variety of tool holders:

- Straight Row Tool Holders: Offer the best cost-effectiveness with direct tool clamping and low maintenance costs.

- Four-Station Manual Tool Holders: Allow for manual adjustment of tool tip angles, though they require more processing space.

- Automatic Rotating Electric Tool Holders: These holders rotate automatically, eliminating the need for manual tool changes. However, they can be costly to repair if damaged.

4.3 Linear Guide Rails

The alloy refurb machine is equipped with linear guide rails, which move faster and are more wear-resistant compared to traditional cast iron guide rails. Even if wear occurs, these can be directly replaced to restore factory standards, representing a high-end configuration.

5. How Can an Alloy Refurb Machine Benefit Car Owners?

5.1 Maintaining Vehicle Value

By refurbishing damaged rims, an alloy refurb machine helps maintain the vehicle’s overall value. This is crucial for car owners looking to resell or trade in their vehicles, as well-maintained wheels can significantly enhance resale value.

5.2 Reducing Economic Losses

For second-hand car dealers, having a wheel repair machine (Rad reparatur maschine)on-site can reduce economic losses associated with damaged inventory. By quickly repairing rims, dealers can keep their vehicle stock in excellent condition, making them more appealing to potential buyers.

6. What Should You Consider When Choosing an Alloy Refurb Machine?

6.1 Features and Functionalities

When selecting an alloy refurb machine, consider the features that will best meet your operational needs. Look for machines with advanced detection capabilities, efficient programming options, and versatile tool holders. The presence of a wheel repair lathe (Máy sửa chữa bánh xe)or wheel CNC machine (Tekerlek tamir makinesi)can also enhance functionality.

6.2 Customization Options

Taian Haishu offers customization options tailored to the specific requirements of different customers. Whether you need voltage adjustments or specific functionalities, it’s important to choose a machine that meets your unique needs.

7. How to Get Started with an Alloy Refurb Machine?

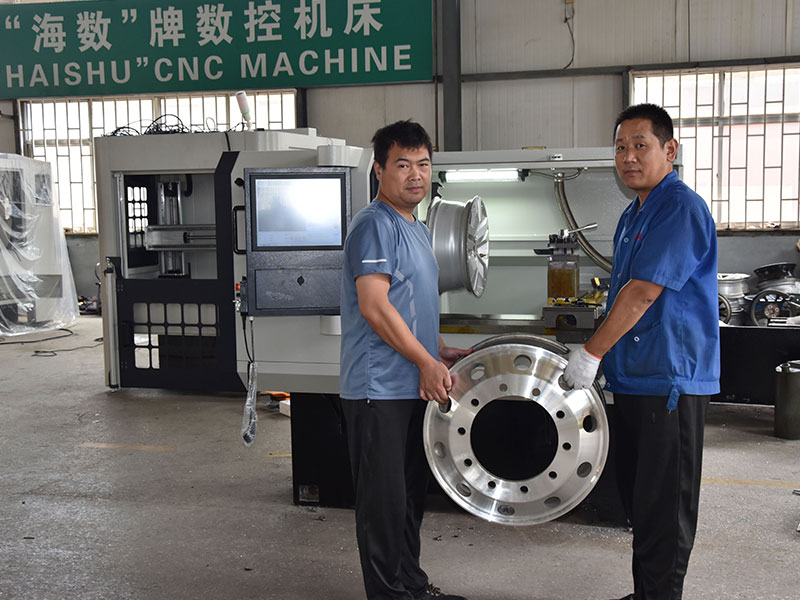

7.1 Visit Taian Haishu

To understand the full capabilities of Taian Haishu’s alloy refurb machine, we recommend visiting their facility. There, you can operate the machines and see firsthand how they function. Their team is knowledgeable and can provide valuable insights into the various features and benefits.

7.2 Contact for More Information

For those interested in learning more about alloy refurb machines and how they can benefit your business, feel free to reach out via email or follow Taian Haishu’s official website and video channels. The company is committed to providing comprehensive support and information to help you make an informed decision.

8. Conclusion

In summary, an alloy refurb machine is an essential tool for repairing and maintaining alloy wheels. With features like advanced detection systems, customizable programming, and specialized tool holders, these machines can significantly enhance the efficiency and effectiveness of wheel refurbishment processes. By choosing a high-quality alloy refurb machine from Taian Haishu, you can ensure that your car rims are restored to their optimal condition, preserving the value of your vehicles and minimizing economic losses.