1. What Is Machined Alloy Wheel Repair?

Machined alloy wheel repair involves utilizing specialized wheel refinishing lathes to address damage caused by scrapes, bumps, or other impacts to a vehicle’s alloy wheels. This process is essential for restoring wheels to a like-new condition or ensuring they meet the manufacturer’s safety standards. By maintaining or enhancing the value of a vehicle, effective wheel repair can be a significant investment for car owners. So, how should one select the right equipment for this type of repair, and what are the costs associated with alloy wheel repair devices? This article will introduce the wheel repair lathe (máy sửa chữa bánh xe)from Tai’an Haishu, offering a comprehensive understanding of this innovative technology.

1.1 Why Is Machined Alloy Wheel Repair Important?

1.11 Value Preservation

Maintaining the aesthetic and functional integrity of alloy wheels is crucial for preserving a vehicle’s overall value. Damaged wheels can detract from the appearance of a car and may even pose safety risks if not repaired properly.

1.12 Safety Considerations

Wheels that are not properly maintained or repaired can lead to unsafe driving conditions. Ensuring that wheels meet safety standards is essential for both the driver and passengers.

2. How to Choose the Right Machined Alloy Wheel Repair Equipment?

2.1 Factors to Consider

When selecting a wheel repair machine (آلة إصلاح العجلات), it’s important to evaluate several factors including:

- Ease of Use: Look for machines that simplify operation, especially for novice users.

- Technology: Advanced features like laser detection can significantly improve the repair process.

- Versatility: A good machine should be able to handle various types of alloy wheels, including aluminum wheel CNC lathes and diamond cut wheel lathes.

2.2 Equipment Options

Tai’an Haishu has developed a range of fully automatic wheel CNC machines that not only facilitate user operation but also reduce the complexity of the repair process. This innovative approach positions us as a leader in the wheel repair industry.

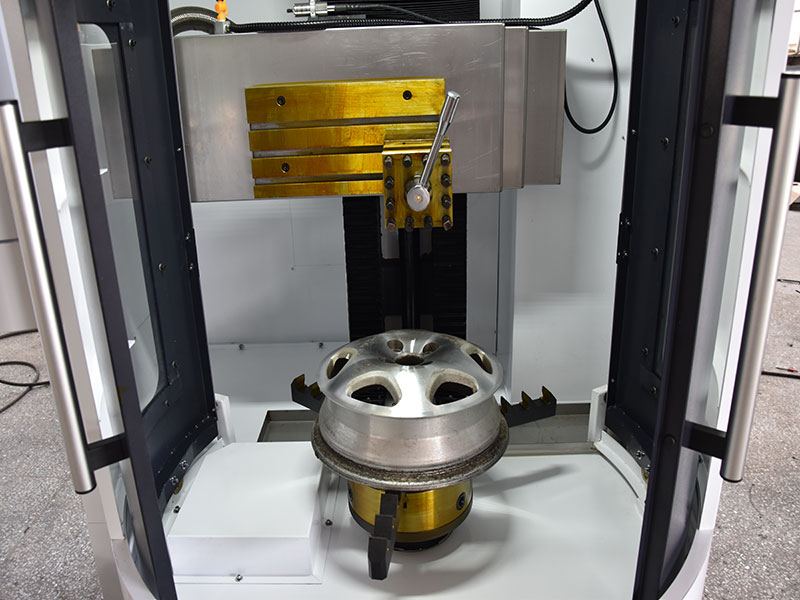

3. What Are the Key Features of Machined Alloy Wheel Repair Machines?

3.1 Advanced Detection Technology

Older wheel repair machines (teker onarım makinesi) required manual curve collection using drawing software and complex G-code programming, which could be cumbersome. In contrast, Tai’an Haishu’s wheel repair system utilizes laser detection technology, enabling users to complete surface detection in under 15 seconds without the need for third-party software for path optimization.

3.2 Types of Detection Methods

- Probe Detection: Ideal for wheels with significant surface undulations but can be time-consuming and carries collision risks.

- Cutting Edge Detection: Suited for intricate wheel surfaces, providing precise detection but taking the longest duration.

This flexibility allows customers to select detection methods based on the specific wheel type they are working on.

4. How Does Machined Alloy Wheel Repair Simplify Operations?

4.1 Automatic and Manual Optimization

Our wheel repair system features both automatic and manual optimization options, eliminating the need for complex manual drawing through software. For smoother surfaces, users can initiate automatic optimization with a simple click. For uneven curves, manual optimization simplifies the process by allowing users to select key points along the detected path.

4.2 User-Friendly Interface

The ease of operation means that even novices can master the system within 30 minutes, compared to traditional methods that might take up to three months to learn.

5. What Are the Post-Repair Processes in Machined Alloy Wheel Repair?

5.1 CNC Program Export

After completing path optimization, users can export CNC programs with customizable names for easy identification. This feature helps avoid errors from manual programming and saves significant programming time.

5.2 One-Click Tool Setting

We offer a one-click tool setting feature, crucial for achieving accurate repair outcomes. This function sets coordinates for both the X and Z axes of the CNC lathe, preventing any misalignment during the machining process.

6. What Tools Are Used in Machined Alloy Wheel Repair?

6.1 Specialized Tooling

With everything set, the system allows for one-click initiation of surface brushing and machining. We provide diamond-specific tools and holders to achieve mirror and brushed finishes, enhancing the aesthetic appeal of the repaired wheels.

6.2 Diamond Cut Wheel Lathes

The use of diamond cut wheel lathes is particularly effective for achieving high-quality finishes on alloy wheels, making them a preferred choice for many repair shops.

7. How Does Tai’an Haishu Support Your Machined Alloy Wheel Repair Needs?

7.1 Commitment to Quality

Tai’an Haishu is a production-oriented enterprise that integrates design, manufacturing, sales, and service. Our CNC repair product line has established partnerships and sales networks in over 80 countries and regions.

7.2 Collaboration Opportunities

We invite potential customers to collaborate with us and welcome visits to our factory. Our commitment to quality and innovation ensures that our clients receive the best possible support for their wheel repair lathe (máquina de reparo de rodas) needs.

8. Conclusion

In summary, machined alloy wheel repair is a vital process that enhances both the safety and aesthetic appeal of vehicles. With advanced features such as laser detection, automatic optimization, and specialized tooling, the wheel repair machines (Rad reparatur maschine) from Tai’an Haishu are designed to meet the diverse needs of the industry. By investing in high-quality CNC lathe machines and utilizing modern technology, repair shops can improve their efficiency and service quality. For more information or inquiries about our products, please contact us or visit our facility.