1. What is a Bent Rim Repair Machine?

A bent rim repair machine is a specialized device designed to restore deformed wheel rims. During vehicle operation, wheel rims can become bent due to collisions, such as hitting a curb or driving over large potholes, as well as from excessive loading and other impacts. Deformed wheel rims can compromise vehicle stability, reduce tire lifespan, and pose safety risks. Understanding the criteria for choosing a wheel hub straightening machine is essential. Here, we will explore the features of the wheel hub straightening machine from Tai’an Haishu Company.

2. How Does a Bent Rim Repair Machine Work?

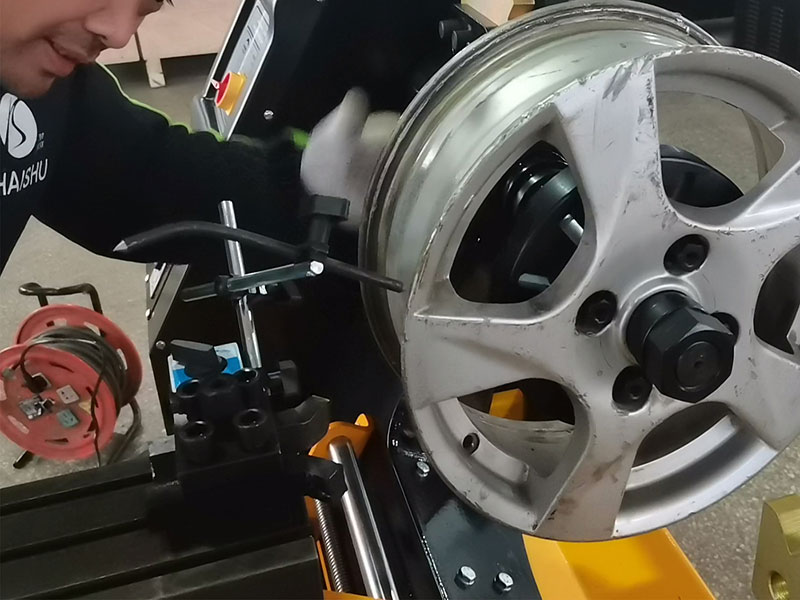

2.1 Understanding the Mechanism

The working principle of a bent rim repair machine typically involves a hydraulic or mechanical pressure system. This equipment applies precise pressure to the deformed sections of the wheel rim, gradually restoring it to its original shape. For example, many machines use adjustable clamps to secure the wheel rim, while hydraulic jacks are employed to exert force from specific angles, allowing bent parts to rebound effectively.

2.2 Features of Tai’an Haishu’s Machine

The wheel hub straightening machine from Tai’an Haishu utilizes an automatic hydraulic adjustment device, enabling the straightening of both straight lines and curves. It can even restore the interior of the wheel rim. The core hydraulic components, including top-quality hydraulic valves from Taiwan, ensure no oil leaks and allow for sensitive operations, eliminating the need for complicated manual adjustments.

3. What Are the Key Components of a Bent Rim Repair Machine?

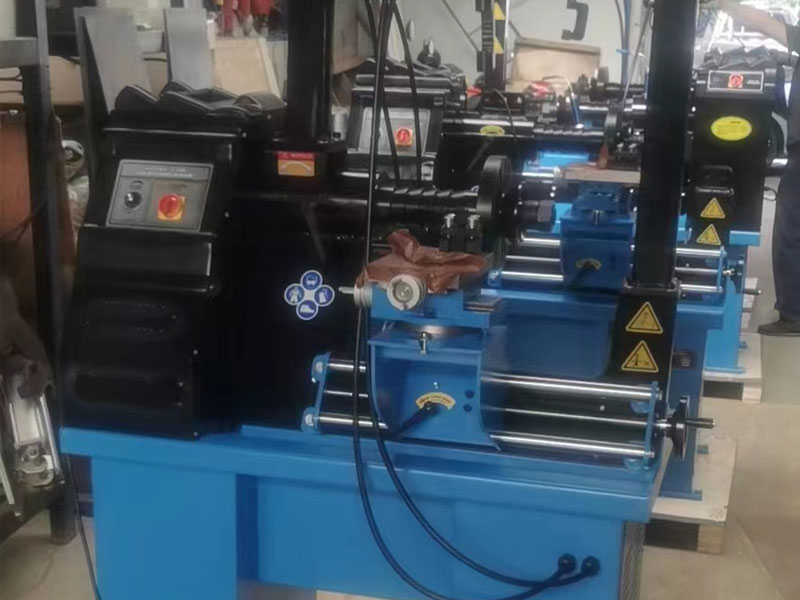

3.1 Structural Overview

A bent rim repair machine generally consists of several essential components: a fixing device, a pressure-applying device, and a control section. The fixing device firmly clamps the wheel rim to prevent movement during the repair process. The pressure-applying device, whether a hydraulic pump or cylinder, generates the necessary force to correct the deformation. The control section allows operators to adjust the pressure’s magnitude, direction, and duration based on the deformation’s specifics.

3.2 Innovative Design Features

The uniquely designed faceplate of the bent rim repair machine can effectively clamp 99% of automobile wheel hubs on the market. This design not only ensures quick and secure fixing but also features accurate center positioning and tight installation screws, making it a reliable clamping method. Hydraulic systems are preferred for straightening due to the higher compression ratio of oil, providing greater stability and ease of operation.

4. Where is a Bent Rim Repair Machine Used?

4.1 Common Applications

The bent rim repair machine is primarily found in automotive repair shops, tire specialty stores, and large after-sales service centers. When a vehicle arrives for repair and a technician identifies a deformed wheel rim, this machine can be utilized to restore it. This capability effectively reduces the cost of wheel rim replacements and enhances repair efficiency.

4.2 Related Equipment

In addition to the bent rim repair machine, related tools such as wheel repair lathes (máquina de reparación de ruedas), wheel CNC machines (machine de réparation de roues), and wheel straighten machines (Rad reparatur maschine) complement the repair process. These devices provide comprehensive solutions for wheel maintenance and restoration, enabling facilities to offer a full range of wheel repair services.

5. What Are the Advantages of Using a Bent Rim Repair Machine?

5.1 Benefits of Hydraulic Systems

Using hydraulic systems in a bent rim repair machine offers significant advantages. The compression ratio of oil is higher than that of gas, allowing for greater and more stable force application. This feature makes operations more efficient and user-friendly. Furthermore, the integration of servo motors and frequency converters enhances system control, enabling quick start-stop functions with low noise and high torque, which are highly valued by customers.

5.2 Cutting and Shaping Functions

Moreover, this machine comes equipped with 360-degree cutting tools that can directly cut welded parts. This dual functionality facilitates both shaping and cutting, allowing for immediate preliminary wire drawing processing, thereby improving operational efficiency.

6. How Does Tai’an Haishu Support Customers with Bent Rim Repair Machines?

6.1 Comprehensive Customer Service

Tai’an Haishu Company is a trusted manufacturer of bent rim repair machines, providing professional ODM integrated design services. Customers can opt to use their own branding or submit specific designs for customization. The commitment to quality ensures that the produced machines are both affordable and reliable, with partnerships extending to over 60 countries and regions worldwide.

6.2 Training and Support Resources

To assist users further, the company offers detailed operation instructions and video tutorials, helping to alleviate any concerns regarding machine usage. Their dedicated service team is available 24/7 to address inquiries, ensuring customer satisfaction and confidence in their equipment.

7. What Does the Future Hold for Bent Rim Repair Machines?

7.1 Market Trends

As the automotive industry continues to advance, the demand for efficient bent rim repair machines is expected to grow. Innovations in technology will likely lead to more sophisticated wheel repair lathes (tekerlek onarım makinesi), wheel CNC machines (آلة إصلاح العجلات), and rim repair machines (máy sửa chữa bánh xe), enhancing the capabilities of wheel straightening and repair processes.

7.2 Conclusion

In conclusion, the bent rim repair machine is an essential tool in the automotive repair industry. Its ability to restore deformed wheel rims not only improves vehicle safety but also enhances repair shop efficiency. With companies like Tai’an Haishu leading the way in quality manufacturing and customer support, the future of wheel repair technology looks promising. We invite customers to visit our factory to witness our manufacturing capabilities firsthand, ensuring you choose a reliable partner for your wheel repair needs. Your inquiries are always welcome!