1. What is a Spoke Repair Machine?

A spoke repair machine is a specialized wheel hub repair machine designed to restore car wheel hubs that have been scratched during driving or distorted due to excessive pressure. The spokes, which connect the rim to the center, are crucial for the overall integrity of the wheel. Damage from roadside debris, collisions, or deformation can compromise driving safety. To effectively refurbish car wheel hubs, combining the functionalities of a wheel hub shaping machine and a wheel hub repair lathe is essential. In this article, we will explore the configurations and advantages of the CNC wheel hub repair machines (آلة إصلاح العجلات) offered by Tai’an Haishu Company.

2. How Does a Spoke Repair Machine Work?

2.1 The Initial Assessment

Before using a spoke repair machine, it is vital to assess whether the car wheel hub is deformed. If deformation is present, the first step is to utilize a wheel hub straightening machine (Máquina de Reparación de Ruedas) to restore the wheel’s shape.

2.2 The Role of Wheel Repair Machines (Tekerlek Onarım Makinesi)

The rim repair machine is capable of addressing various sizes and types of car rims, including aluminum alloy rims. This hydraulic rim repair machine is specifically engineered to correct wheel hub deformations. It operates on a hydraulic system that utilizes heat to facilitate shaping and correction, followed by rapid cooling to restore the hub to its original shape.

2.3 The Repair Process

Initially, the wheel hub is secured using specialized screws and a faceplate. A special alignment pin is then used to manually rotate and identify deformed areas. The damaged sections are softened through heating and corrected using a hydraulic jack device. This process is usually completed within 30 minutes for each wheel hub.

3. What Are the Key Features of a Spoke Repair Machine?

3.1 Hydraulic Drive Mechanism

Selecting a wheel hub correction machine (เครื่องซ่อมล้อ) with a hydraulic drive is crucial for reliability. Over time, hydraulic valves can experience oil leakage and pressure loss. Tai’an Haishu Company uses high-quality Taiwan-brand hydraulic valves to ensure consistent performance.

3.2 Frequency Converters for Versatility

The incorporation of frequency converters allows the machine to meet various rotational acceleration needs. This feature, combined with crab-claw-shaped long hydraulic jack claws, significantly enhances shaping efficiency and accuracy.

4. How is the Surface of the Wheel Hub Repaired?

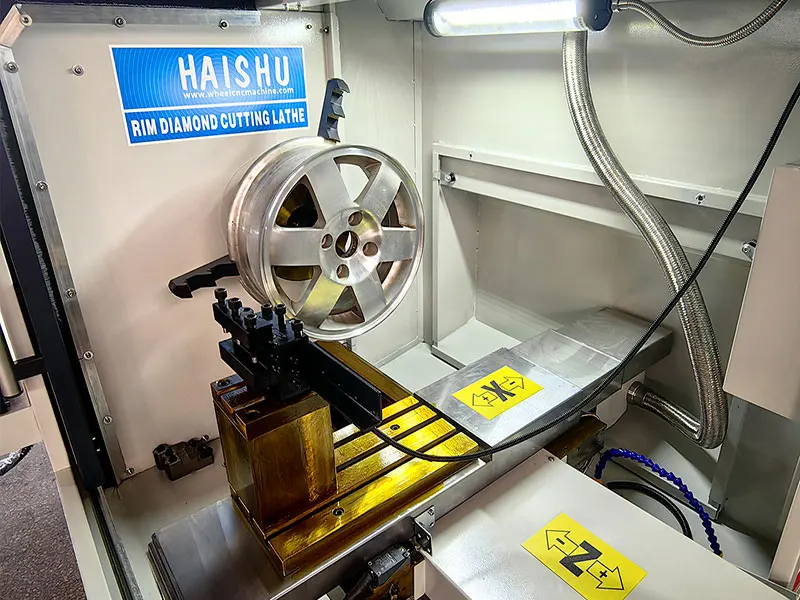

4.1 Using Diamond Cutting Tools

After correcting the wheel hub, the next step involves repairing the surface, particularly the spokes. This process employs specialized diamond cutting tools to refine the spokes, restoring them to a bright, new appearance, thereby preserving the wheel hub’s value.

4.2 Custom Refurbishment Options

Many car beauty shops offer customized refurbishment services that can give wheel hubs unique finishes, such as rainbow colors when light reflects off them. This customization not only enhances aesthetics but also adds to the overall appeal of the vehicle.

5. What Are the Main Configurations of a Spoke Repair Machine?

5.1 Advanced Clamping Devices

Tai’an Haishu Company’s spoke repair machines are equipped with specialized wheel hub fixture chucks. These elongated claws are crafted using precise wire cutting techniques, allowing for quick and secure fixation of the wheel hub.

5.2 Detection Methods

The spoke repair machine supports multiple detection methods, including laser detection, probe detection, automatic tool detection, and manual tool detection. Users can select any of these methods to gather surface data from the spokes efficiently.

5.3 Data Conversion and Optimization

Once the data is collected, it is processed through precise algorithms. The machine offers two optimization methods: automatic and manual. Customers can choose their preferred optimization method, making it easy to generate CNC programs with just one click, significantly reducing manual programming time.

6. How User-Friendly is the Spoke Repair Machine?

6.1 One-Click Operations

The spoke repair machine is designed for ease of use, allowing even those with no prior experience to master its functions within approximately 30 minutes. The one-click tool setting feature simplifies the entire processing experience, making it accessible for all users.

6.2 Multiple Operation Modes

Tai’an Haishu Company’s focus on user-friendly design extends to the implementation of multiple one-click operation methods, ensuring that the wheel hub repair machine (Rad reparatur maschine) is straightforward and efficient to operate.

6. When Should You Use a Spoke Repair Machine?

6.1 Signs of Damage

If you notice scratches or deformation on your car spokes, it is essential to refurbish them using a combination of an alloy wheel hub repair machine and a wheel hub straightening machine (휠 수리 기계). Addressing these issues promptly can prevent further damage and enhance driving safety.

6.2 Comprehensive Service Solutions

In addition to spoke repair machines, Tai’an Haishu Company offers a complete range of service solutions, including wheel hub polishing machines (Máquina de Reparação de Rodas), wheel hub ovens, sandblasting machines, and spray booths. These additional tools ensure that every aspect of wheel hub maintenance is covered.

7. Conclusion

A spoke repair machine is an integral tool for maintaining the safety and aesthetics of vehicle wheels. Combining the functionalities of wheel repair lathes (Máy sửa chữa bánh xe)and wheel CNC machines (Wiel diagnose machine)provides comprehensive solutions for wheel hub restoration. Tai’an Haishu Company stands out as a professional manufacturer, offering advanced spoke repair machines equipped with the latest technology. We invite you to visit our factory and discuss your wheel hub repair needs directly. Your vehicle’s safety and appearance are our top priorities, and we are here to provide the best solutions for your wheel maintenance requirements.