How to Choose the Right Alloy Wheel Lathe for Sale?

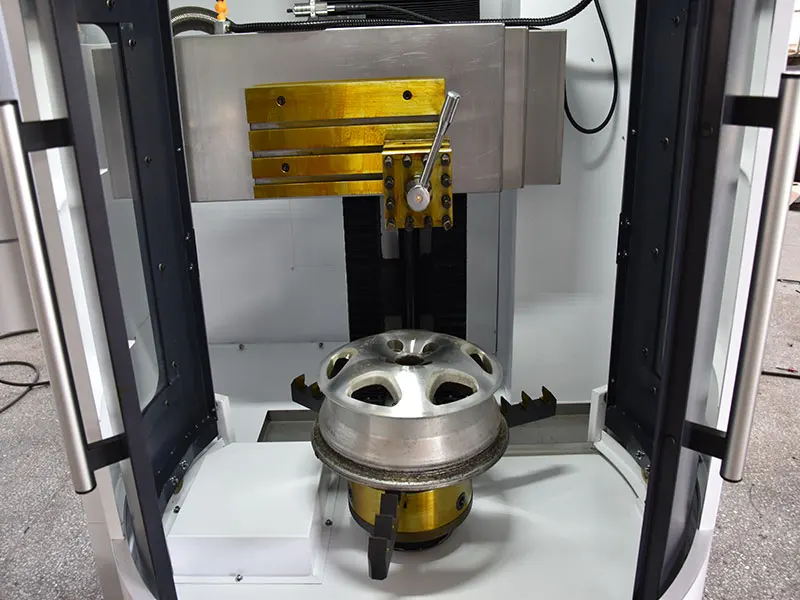

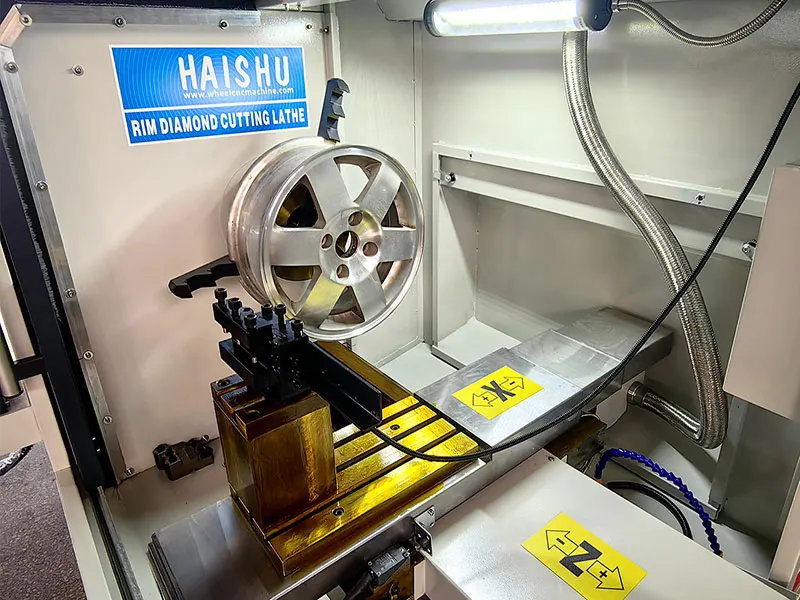

An “Alloy Wheel Lathe for Sale” refers to a specialized machine used to repair and restore automotive alloy wheels. These machines are essential for fixing surface damage, such as scratches, scuffs, and corrosion, which can occur during regular vehicle use. A wheel repair lathe (पहिया मरम्मत मशीन)removes a thin layer of material from the damaged wheel surface using precision turning, restoring it to a smooth and flat condition.

For example, scratches and scuffs can form when alloy wheels scrape against curbs or collide with road debris. A diamond-cut wheel lathe can precisely remove these imperfections, restoring the wheel to its original appearance. Similarly, corrosion is a common issue in coastal regions where wheels are exposed to salt-laden air. A wheel CNC machine can effectively remove the corroded layer, preparing the surface for subsequent treatments like painting or electroplating.

Selecting the right aluminum wheel CNC lathe is crucial for ensuring high-quality repairs, optimizing efficiency, and meeting your business’s demands. Below, we’ll explore the key features and considerations to help you choose the best wheel repair machine (Máquina de Reparación de Ruedas) for your needs.

Why Are Automation Features Important in an Alloy Wheel Lathe for Sale?

The Role of Automation in Wheel Repair Machines

Automation is a critical factor when choosing a wheel repair lathe (Jant Tamir Makinesi). Manual operations are time-consuming and prone to errors, requiring skilled labor to achieve consistent results. Automated aluminum wheel repair machines (Machine de Réparation de Roues)simplify these processes, offering faster and more accurate repairs while reducing operator dependency.

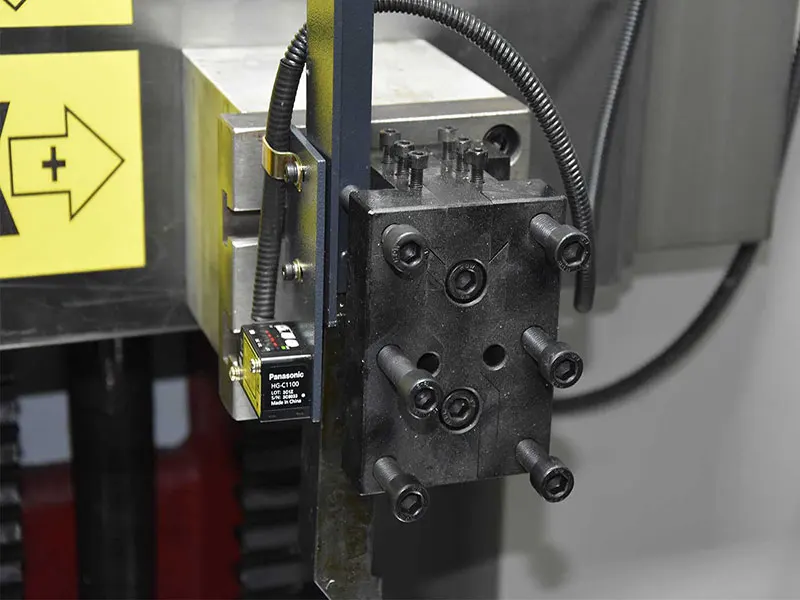

For example, advanced wheel CNC machines from leading manufacturers like Taian Haishu come with laser scanning technology that can measure a wheel’s surface in just 15 seconds. This automated scanning ensures precise turning without manual errors. Features such as one-click tool setup and automatic CNC programming further streamline operations, enabling even inexperienced operators to achieve professional-grade results.

Benefits of Automation

- Increased Efficiency: Automated processes reduce repair time and improve workflow.

- Enhanced Precision: Automation ensures consistent and high-quality results.

- Ease of Use: Simplified operations make the machine accessible to operators of all skill levels.

- Error Reduction: Minimizes human errors, leading to more reliable repairs.

Automation in a diamond cut wheel lathe not only improves efficiency but also increases profitability by reducing labor costs and turnaround times.

How Does High-Precision Machining Improve an Alloy Wheel Lathe for Sale?

Precision in Wheel Repair Machines

High-precision machining is essential for achieving flawless results in alloy wheel repairs. A wheel repair lathe (Máy Sửa Chữa Bánh Xe) with advanced precision ensures that the repaired wheel surface is smooth, uniform, and free of defects. Without precise machining, the quality of repairs may be compromised, leading to poor performance and aesthetics.

Modern aluminum wheel CNC lathes use servo motor drives and encoder feedback technology to maintain machining accuracy. This technology ensures a precision level of 0.01mm or better, making it possible to perform intricate repairs with exacting standards. Additionally, linear guides allow for higher-speed movements while maintaining accuracy, producing polished and flawless wheel surfaces.

Why Precision Matters

- Enhanced Aesthetics: Ensures the wheel looks as good as new after repair.

- Improved Safety: Guarantees that the wheel meets industry safety standards.

- Customer Satisfaction: High-quality repairs lead to better customer retention.

When selecting an aluminum wheel repair machine (Rad reparatur maschine), prioritize those with advanced precision features to ensure optimal results.

What Multifunctionality Should You Expect in an Alloy Wheel Lathe for Sale?

The Importance of Multifunctionality

A multifunctional wheel CNC machine allows you to perform various repair tasks, such as machining, brushing, and polishing, without needing additional equipment. This versatility saves time, reduces costs, and increases overall productivity, making it an invaluable asset for any repair business.

Modern aluminum wheel repair machines (Máquina de Reparação de Rodas)integrate multiple functions, enabling seamless transitions between tasks. For instance, a diamond cut wheel lathe can handle everything from restoring smooth surfaces to adding brushed finishes, eliminating the need for separate machines.

Benefits of Multifunctionality

- Time Savings: Reduces the time spent switching between machines.

- Cost Efficiency: Eliminates the need for additional equipment, lowering operational costs.

- Versatility: Accommodates a variety of wheel sizes and repair requirements.

By investing in a multifunctional wheel repair lathe (เครื่องซ่อมล้อ), you can enhance the flexibility and efficiency of your operations.

How Easy is the System Operation of an Alloy Wheel Lathe for Sale?

Simplified Operation for Better Productivity

Ease of use is a crucial consideration when choosing a wheel repair machine (휠 수리 기계). A user-friendly interface reduces the learning curve, allowing operators to quickly adapt to the machine and perform repairs efficiently. This is particularly important for businesses with high turnover or limited access to skilled labor.

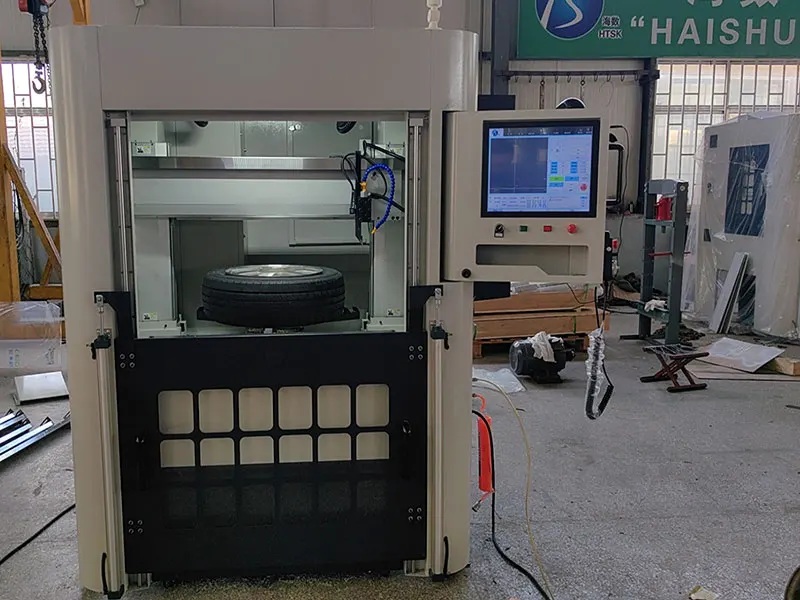

Modern aluminum wheel CNC lathes feature intuitive systems with one-click operational functions, enabling simplified processes. For example, Taian Haishu’s advanced systems support multiple languages, including English, Spanish, Russian, Portuguese, Polish, Vietnamese, and Turkish, catering to a global customer base.

Features That Enhance Usability

- One-Click Operations: Simplifies complex processes, making them accessible to all users.

- Training Resources: Video tutorials and on-site training ensure operators can master the system quickly.

- Customizable Interface: Adapts to the needs of different users with multilingual support.

By choosing a diamond cut wheel lathe with user-friendly features, you can improve productivity and reduce downtime in your operations.

How Safe and Stable is an Alloy Wheel Lathe for Sale?

Ensuring Operator Safety

Safety is a top priority when operating a wheel repair lathe (Maszyna do Naprawy Kół). Machines must include features that protect operators during use, such as safety doors, emergency stop functions, and overload protection. These safeguards are essential for preventing accidents and ensuring a safe working environment.

Stability for Long-Term Use

Stability is equally important, especially in high-volume repair shops. Reliable aluminum wheel CNC lathes are designed to maintain consistent performance during extended use. Features such as quick-change clamps make wheel mounting and removal faster, enhancing workflow efficiency.

By investing in a stable and safe wheel CNC machine, you can ensure smooth and uninterrupted operations while prioritizing operator well-being.

Why is After-Sales Support Important for an Alloy Wheel Lathe for Sale?

Comprehensive Support for Your Business

After-sales support is a vital consideration when purchasing a wheel repair machine (Macchina per la Riparazione delle Ruote). Reliable support ensures that your machine remains operational and performs at peak efficiency throughout its lifecycle. Leading manufacturers, such as Taian Haishu, offer robust after-sales services, including 24/7 phone and email support and on-site assistance.

Additional Benefits

- Free Spare Parts: Replacement parts are often provided free during the warranty period.

- Affordable Maintenance: Post-warranty parts are available at cost price, minimizing operational expenses.

- Lifetime Software Upgrades: Ensures your aluminum wheel CNC lathe stays updated with the latest features.

By choosing a reputable manufacturer with strong after-sales support, you can maximize the value of your investment in a wheel repair lathe.

Why Choose Taian Haishu for an Alloy Wheel Lathe for Sale?

Taian Haishu is a trusted name in the wheel repair machine (آلة إصلاح العجلات)industry, offering cutting-edge solutions for alloy wheel restoration. Their machines combine precision, automation, multifunctionality, and user-friendly operation, making them the ideal choice for professionals in the automotive repair sector.

Whether you need a diamond cut wheel lathe, an aluminum wheel CNC lathe, or a versatile wheel CNC machine, Taian Haishu provides tailored solutions to meet your needs. With their robust after-sales support and innovative technology, Taian Haishu ensures exceptional performance and long-term value for your business.

If you’re looking for a reliable alloy wheel lathe for sale, contact Taian Haishu today to explore their range of high-quality machines.