Alloy Rim Repair CNC: Elevating Wheel Refurbishment

Alloy Rim Repair CNC technology marks a significant leap in the automotive repair industry, offering a sophisticated approach to refurbishing alloy rims. This technology encompasses a suite of specialized machines, including the wheel repair lathe, wheel CNC machine, wheel hub repair machine, and alloy wheel CNC lathe, which together streamline the repair process and ensure exceptional results.

Understanding Alloy Rim Repair CNC Technology

The Process of Repairing Alloy Rims

It process begins with a careful evaluation of the damaged rim. Utilizing advanced equipment like the wheel repair lathe and wheel CNC machine, technicians can accurately identify and measure any damage.

Initial Assessment of the Wheel Repair Lathe

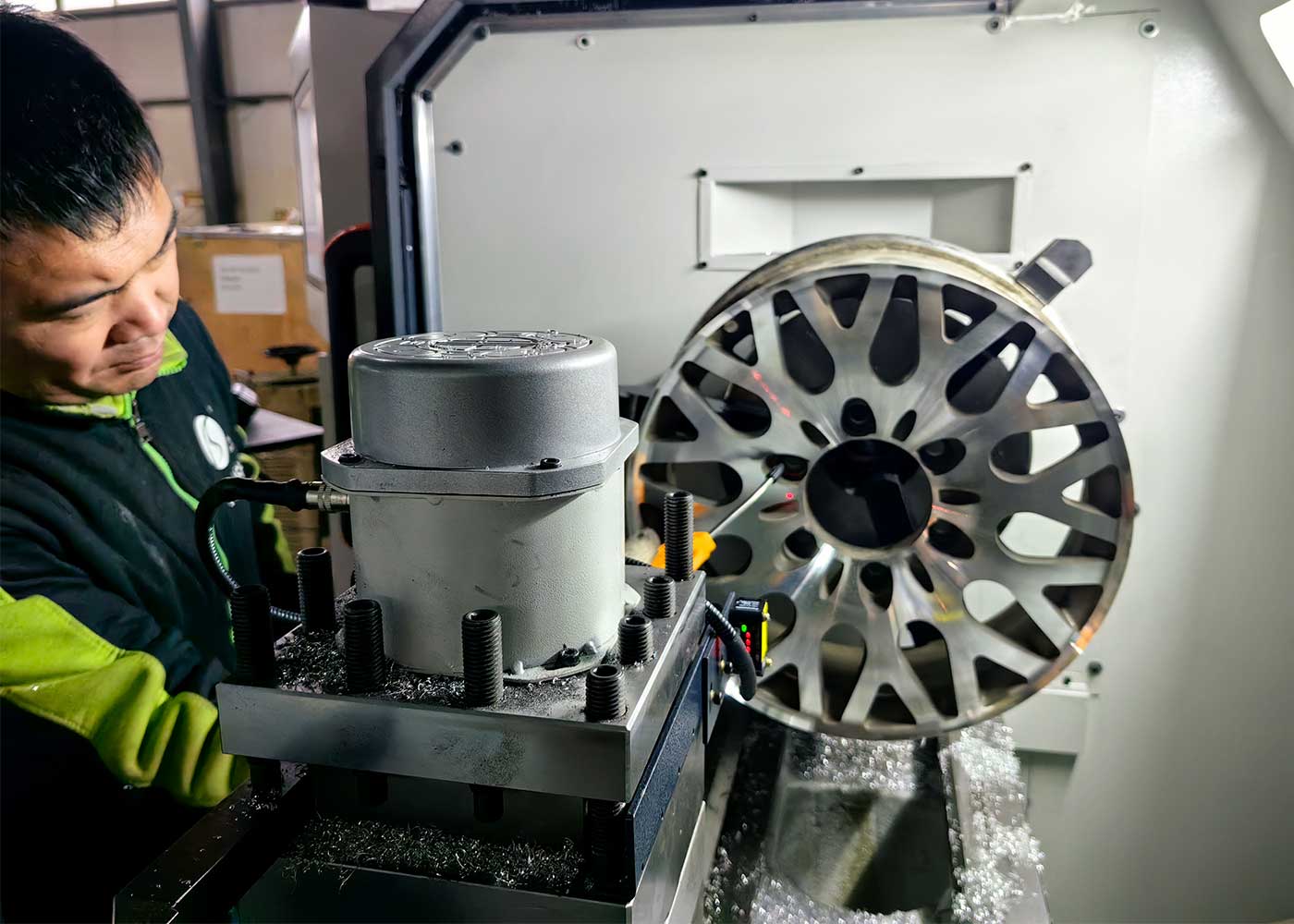

The damaged alloy rim is first mounted onto a wheel repair lathe, a pivotal component of the Alloy Rim Repair CNC system. Here, the lathe assesses the rim’s damage by spinning the wheel at high speeds.

Precision Scanning with Wheel CNC Machine

Next, a wheel CNC machine equipped with high-tech scanners maps the geometry of the rim, allowing for an accurate repair plan tailored to the specific damage.

Machining with Alloy Wheel CNC Lathe

The core of the repair process is the alloy wheel CNC lathe, which meticulously reshapes the damaged areas, returning the rim to its original profile and aesthetic quality.

Comprehensive Repairs with Wheel Hub Repair Machine

If the damage extends to the wheel hub, a wheel hub repair machine ensures a complete and thorough repair, restoring the entire wheel assembly to optimal functionality.

The Advantages of Alloy Rim Repair CNC Machines

Q: What makes Alloy Rim Repair CNC machines stand out in rim repair?

A: wheel hub machining machines like the wheel repair lathe and alloy wheel CNC lathe bring unparalleled precision to the repair process. These machines can achieve a level of accuracy that manual repair methods cannot match, ensuring that rims are restored to their original condition both functionally and aesthetically.

Q: How do service providers benefit from using vertical wheel repair lathe technology?

A: By integrating alloy wheels repair lathe machines, such as the wheel CNC machine and wheel hub repair machine, service providers can significantly boost their efficiency. Repairs that used to take hours can now be completed much faster, which not only improves turnaround times but also enhances customer satisfaction through quick and reliable service.

The Impact of Diamond cut wheel repair on Automotive Services

Precision and Efficiency in Rim Restoration

The precision and efficiency offered by CNC wheel lathe machines have revolutionized the way automotive service providers approach alloy rim restoration. The wheel repair machine, at the heart of this innovation, ensures that each rim is repaired with the utmost care, preserving the integrity of the wheel and ensuring safety for the vehicle’s occupants.

Cost-Effective Solution for Rim Damage

With the ability to accurately machine and repair rims, Rim repair equipment technology reduces the need for costly rim replacements. This not only saves money for customers but also promotes sustainability by extending the life of existing rims.

Ensuring Quality and Safety

After the repair process, a thorough inspection guarantees that the rim meets stringent quality and safety standards. Service providers can assure their customers that the repaired rims are as reliable as new ones, fostering trust and confidence in their services.

Conclusion

Alloy Rim Repair CNC technology, through the use of sophisticated equipment like the wheel repair lathe, wheel CNC machine, wheel hub repair machine, and alloy wheel CNC lathe, has set a new benchmark in alloy wheel refurbishment. This technology delivers precision, efficiency, and cost savings, making it an invaluable asset for automotive service providers. As the industry continues to innovate, shops equipped with Alloy Rim Repair CNC technology will remain at the forefront, offering superior service and impeccable results for every alloy rim that rolls into their workshop.