What Are the Specifications of Alloy Wheel Refurbishment Equipment UK CK6180W?

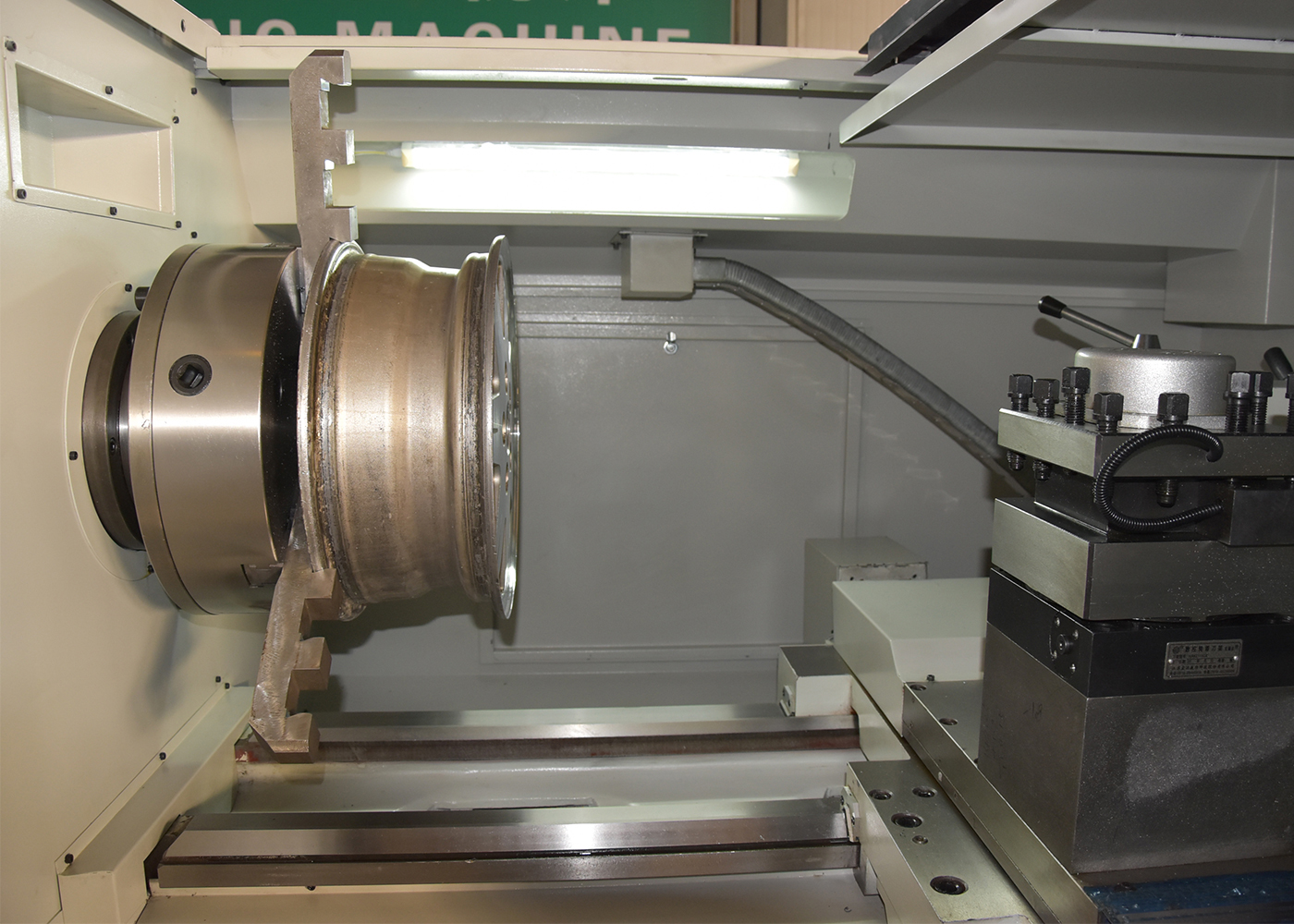

The CK6180W Alloy Wheel Refurbishment Equipment, designed and manufactured by Haishu Machinery, offers high precision, cost-effective performance, and a space-saving design. This equipment is widely utilized in auto 4S shops, wheel repair shops, and more. Featuring a cast steel bed, high-precision spindle, fixing chuck and feed mechanism, imported CNC system, automatic measuring system, brand-name servo motor, and auxiliary components like lubrication and cold light, our wheel repair lathe ensures reliable and efficient operation.

How Does Alloy Wheel Refurbishment Equipment UK CK6180W Enhance Wheel Repairs?

In addition to general wheel repairs, the CK6180W wheel repair machine also caters to wheel updates, a trending service in repair garages. With increasing attention on wheels, immediate remediation of damages has become crucial. The complexities of hub surface problems arise from varying materials and wear resistance. Our technicians refurbish hubs based on specific wear, fading, and scratching conditions, requiring skilled expertise. The CK6180W wheel CNC machine addresses these challenges effectively.

What Advanced Features Does Alloy Wheel Refurbishment Equipment UK CK6180W Offer?

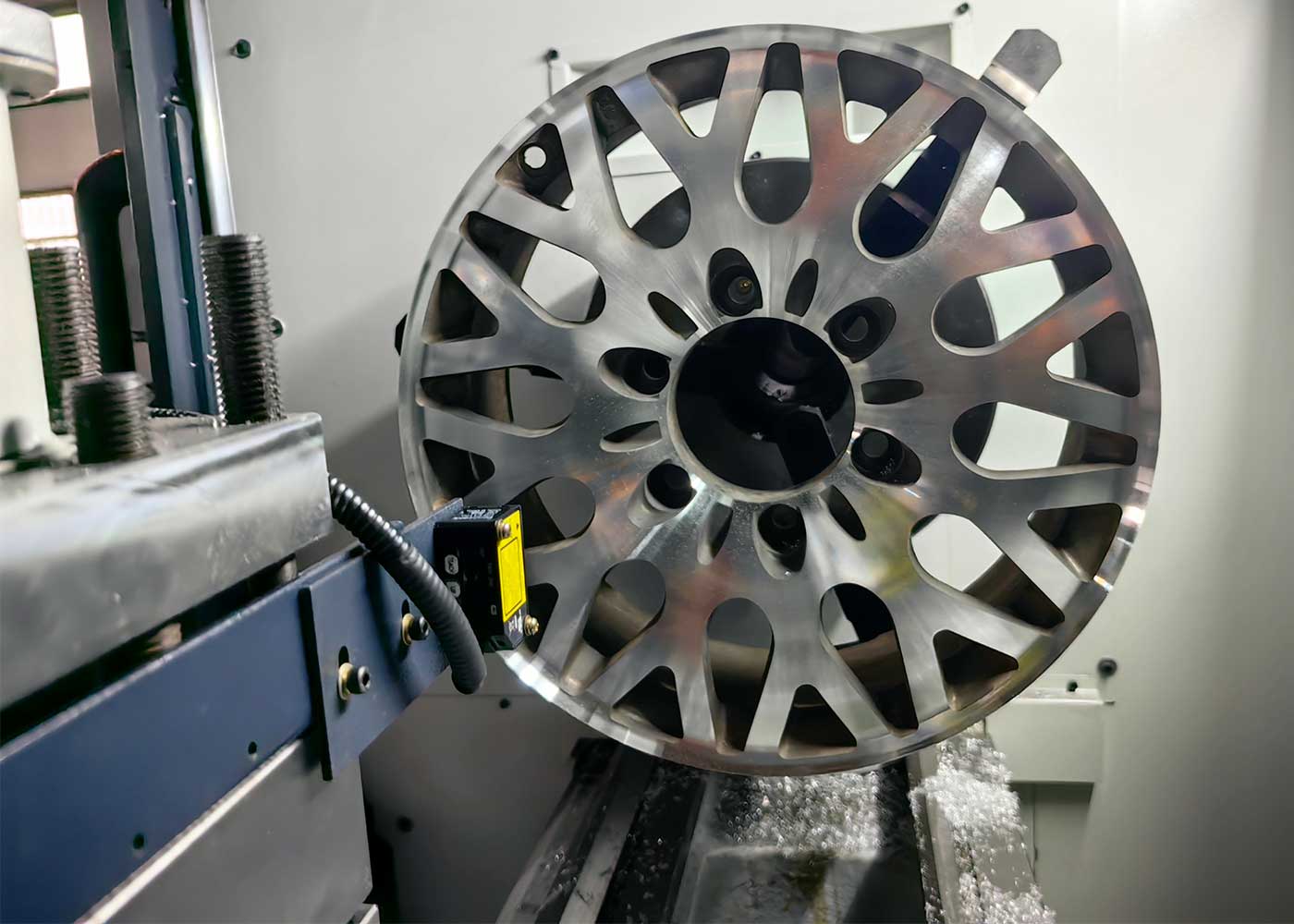

Equipped with a swivel electric tool holder and a laser probe, the equipment enables quick access to the hub surface, accommodating varying skill levels. Furthermore, customization options allow us to match the customer’s preferred wheel color. Beyond surface repairs, our wheel CNC machine can modify the wheel’s curvature, providing a personalized and distinctive touch. The CK6180W alloy wheel refurbishment equipment meets our customers’ unique requirements. While powerful, our wheel lathes are user-friendly, allowing easy mastery within a few hours of training.

Moreover, the stable overall structure of our alloy wheel refurbishment equipment ensures smoother and more stable wheel repairs. The electric tool holder enables quick tool changes without manual probe removal, enhancing convenience and efficiency. Key features include automatic laser scanning, fast measurement, automatic wheel data acquisition and storage, self-developed CNC software with program optimization, precise and fast wheel processing, user-friendly touch screen operation, X/Z axis measurement and machining, three-color warning lights, automatic lubrication system, and diamond cutting capabilities.

Why Choose Haishu Machinery for Alloy Wheel Refurbishment Equipment UK CK6180W?

Are you searching for professional and versatile alloy wheel refurbishment equipment? Look no further than the CK6180W, designed to handle wheels of all sizes with precision and efficiency. Our commitment to customer satisfaction and providing detailed information throughout the negotiation and transaction process ensures a smooth and transparent experience for customers like Mr. Kim from Bulgaria. He discovered our company online and was impressed by our top-quality alloy wheel refurbishment equipment. After evaluating his needs, we recommended the CK6180W as the ideal solution, and we provided him with detailed documentation, including a working video, technical parameters, and detailed photographs of the machine.

To cater to Mr. Kim’s specific preferences, we offered him a choice between a touch probe and a laser probe, and two system options: the SYNTEC CNC system or the touch screen system. Ultimately, Mr. Kim chose the SYNTEC CNC system and the laser probe due to their faster detection speed and versatility. Upon completion of the machine, we provided Mr. Kim with a final working video and pictures for his approval. Satisfied with the equipment, he promptly settled the remaining balance, and we initiated the shipment process.

Welcome to Taian Haishu Machinery Co., Ltd., the leading designer and manufacturer of CNC machines specializing in automobile wheel production and repair solutions. Since our establishment in 2001, we have continuously strived to be at the forefront of CNC lathe design and manufacturing. With over 30 talented experts and a state-of-the-art 12,000-square-meter factory, we are committed to delivering excellence to customers worldwide. We are actively seeking partners worldwide to join us on our journey of providing top-notch CNC machine solutions.