Unlocking Efficiency with Alloy Wheels Restoration CNC Lathe CK6160Q

Revolutionizing the Wheel Restoration Industry

The Alloy Wheels Restoration CNC Lathe CK6160Q is redefining the standards of wheel refurbishment. This machine boasts a self-developed CNC system, high efficiency, compact structure, touch screen, and user-friendly operation. It’s engineered to restore alloy wheels up to 24 inches, catering to the ubiquitous diamond-cut alloys that are a staple on modern vehicles.

Alloy wheels face daily wear from sidewalks and regular usage, losing their showroom shine. The CK6160Q wheel CNC machine steps in to offer a quick, cost-effective solution, returning wheels to their pristine condition in approximately 20 minutes for a standard 20″ wheel.

Expanding Success in Spain

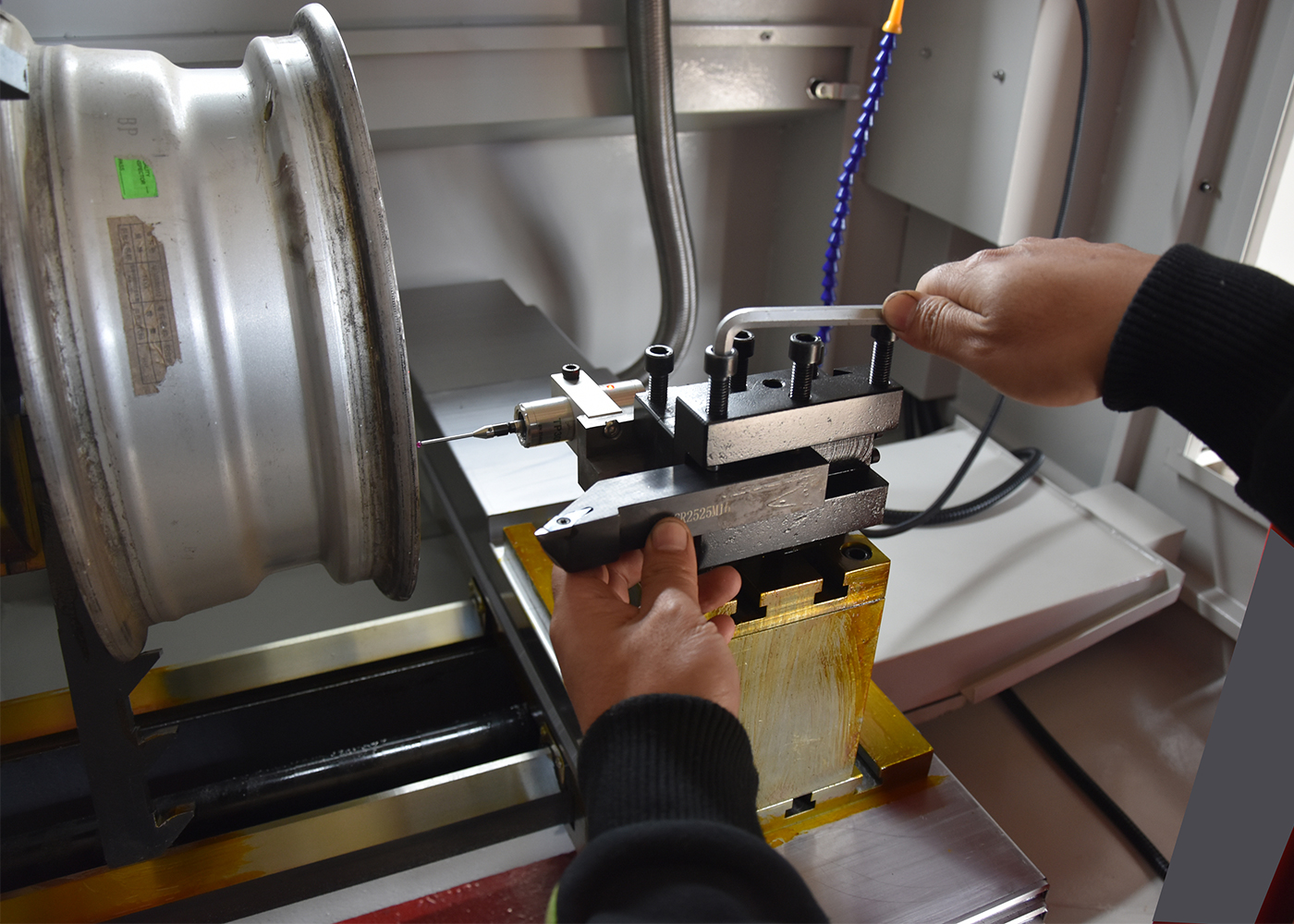

A Spanish 4s shop owner, having witnessed the efficiency of our wheel repair lathe firsthand, has decided to double his capacity for excellence by ordering another set. Tailoring to his specific needs, we’ve integrated a Windows 10 system into the wheel repair machine and added both probe and laser detection for unparalleled precision. The customization didn’t end there; we also adapted the mandrel for optimal wheel clamping.

After the full payment was settled, we showcased the operational prowess of the CK6160Q through a detailed video, earning high praise and anticipation for future collaboration.

Cutting-Edge Features of the CK6160Q

Precision and Performance

The Alloy Wheels Restoration CNC Lathe CK6160Q is equipped with either laser scanning or probe click measurement for supreme accuracy. It automatically saves wheel data, allowing for easy retrieval of machining programs. Its software is the result of independent development, ensuring constant optimization for superior wheel processing.

User-Centric Design

The lathe’s operation is simplified through a touchscreen interface, supporting multiple languages to cater to a global market. The X/Z axis measurement facilitates meticulous surface and circumferential machining.

Enhanced Quality

An automatic lubrication system ensures the machine’s longevity, while the diamond tool turning feature produces a smoother wheel surface. For those looking to delve deeper into the machine’s capabilities, there’s a computer teaching function available.

Customization

Understanding that needs vary, the Alloy Wheel CNC Machine can be customized to meet individual client requirements.

Haishu Machinery: Pioneering Wheel Repair Innovations

Haishu Machinery stands at the forefront of R&D and manufacturing for the mobile wheel repair lathe sector. With a commitment to bridging the technological gap in China’s auto wheel repair market, our company has forged strategic alliances with top-tier American automotive maintenance firms. The introduction of the alloy wheel repair lathe technology reinforces our mission to spearhead the wheel repair movement, ensuring a greener, more sustainable approach to giving old wheels new life.

Conclusion

The Alloy Wheels Restoration CNC Lathe CK6160Q represents a leap forward in wheel repair technology. With its advanced features, customization options, and unparalleled ease of use, this wheel repair machine is not just a purchase; it’s an investment in efficiency and quality. For those in the wheel restoration business, the CK6160Q is the key to unlocking a new level of service and customer satisfaction.