Aluminum Alloy Wheel Repair Equipment is the high performance wheel repair lathe with an automatic detection scanning programming hub. The wheel repair lathe is further improved based on the original programming automatic wheel repair lathe. Through the stability of the wheel lathe, detection, system programming speed, drawing lines and other aspects are upgraded. Comparing with the manual drawing machine, an automatic wheel machine adopts a laser displacement ranging scanning curve. No need for manual programming to measure the curve. Our alloy wheel lathe has fast operation speed and simple operation. Our company’s wheel CNC machine tool for repairing wire drawing hub, repairing damaged wire drawing hub, after renovation, bright as new!

This German customer is our regular customer. After he used our wheel CNC machine, he was very satisfied, so he wants to buy another Wheel CNC Lathe. After he expressed the request this time, we choose the small Aluminum Alloy Wheel Repair Equipment CK6160Q for him, and he told him he needs this type. Then he requested the PI and pay the deposit immediately.

After the Aluminum Alloy Wheel Repair Equipment completed, we invited him to accept the wheel CNC lathe, he told just send the test video will be ok. He was very relieved about our company and the machine. We sent the test video of the wheel lathe to him and he was very satisfied.

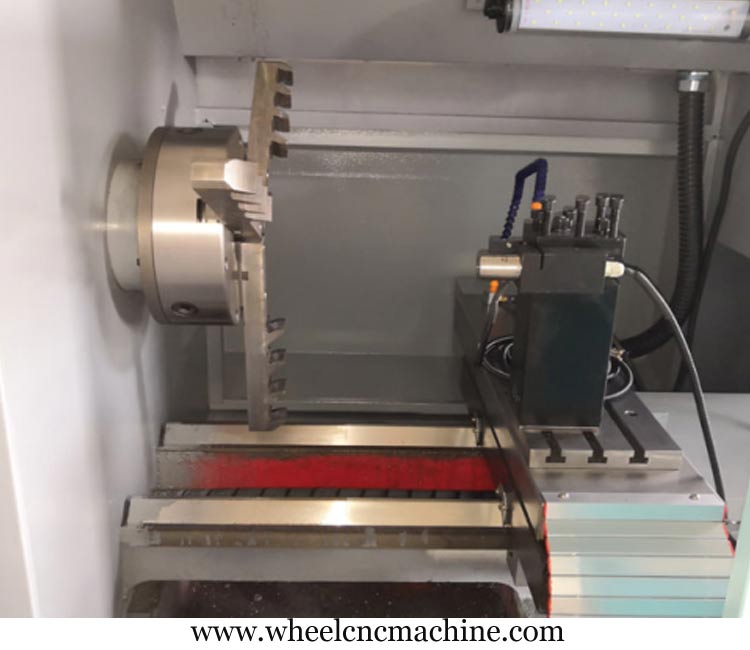

Aluminum Alloy Wheel Repair Equipment CK6160Q Specifications

| Item | Unit | Specifications |

|---|---|---|

| Max Wheel Diameter | inch | 22″ |

| X-axis maximum stroke | mm | 320 |

| Main motor power | Kw | 3 |

| Rial Width | mm | 260 |

| Max. workpiece length | mm | 500 |

| Wheel measuring direction | X,Z | |

| Spindle speed | Factory setting 150~2800 | |

| Fast-moving feed | mm/min | X :5000 Z :8000 |

| Repeat accuracy | mm | X :0.01 Z :0.015 |

| Turret form | Fixed turret,Electric turret (optional) | |

| Section of turning tool | mm | 25×25 |

| Machine size(L×W×H) | mm | 1900×1400×1750 |

| Net weight | Kg | 1300 |

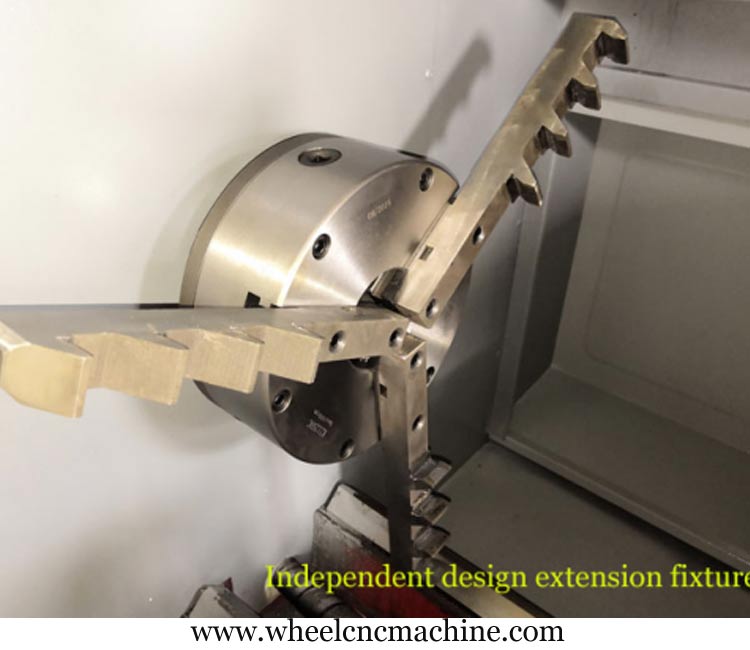

Aluminum Alloy Wheel Repair Equipment CK6160Q Features

1.The Wheel Cutting CNC Lathe has the advantages of simple structure, low cost and high performance price ratio.

2.The Alloy Wheel repair Machine can be selected by laser scanning or probe click measurement.

3.Wheel data is automatically stored, machining program is arbitrarily called out.

4.Software independent development, program automatically optimize

5. Wheel processing is automatic precise and fast

6. The Wheel cnc Machine is operated by touch screen, and the system interface supports many languages.

7.X / Z axis measurement, wheel surface and circumferential machining.

8. The Wheel Diamond Cutting Machine is equipped with an automatic lubrication system.

9.The Wheel Cutting Machine with diamond tool turning, make wheel surface more smooth.

10. The Wheel repair Machine has the teaching function of the computer.

11.The Alloy Wheel cnc Machine can be customized according to customer requirements.

About Haishu Machinery

Haishu Machinery is a product design, R&D, sales and service integrated automotive aftermarket repair application brand, with independent technology development departments to develop products in equipment production, professional technicians with excellent services. In line with the purpose of “environmental protection, economy, and high efficiency”, the company has developed a series of high-tech automobile repair equipment in application technology, We provide Aluminum Alloy Wheel Repair Equipment CK6160Q, Wheel repair Lathe, Wheel straightening machine, brake drum lathe, etc. for automobile rear market terminal stores, and can customize the shape and color of the wheel machine and also configuration, which is welcomed and praised by large customers. Our company follows the principle of “material, material, telling the truth, truthful work”, with a flexible business model, high-quality service to customers, sincere cooperation with friends from all walks of life.