What Is A Brake Lathe?

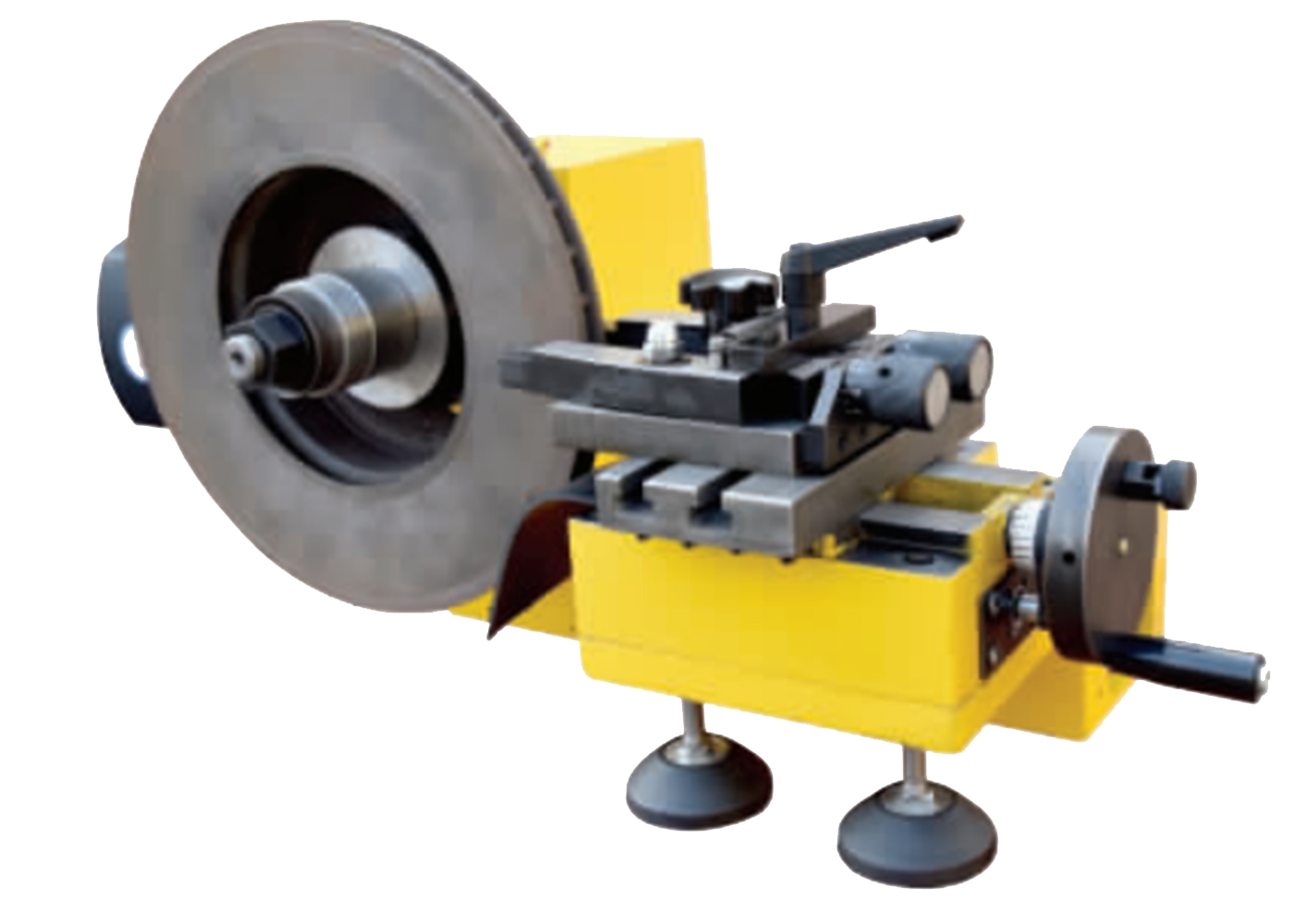

A brake lathe is a specialized equipment used for handling and repairing automotive brake discs. This rotating machine is designed to restore the surface of brake discs, eliminating vibrations and noise during braking. Utilizing a Brake drum lathe involves securing the brake disc onto the machine and rotating the disc’s surface to remove any irregularities and wear. Equipped with cutting tools and grinding wheels, it effectively repairs concave, convex, and worn areas on the brake disc surface. Additionally, a brake lathe can adjust the surface roughness to ensure stability and performance during braking.

By using a Brake drum turning machine, the lifespan of brake discs can be extended, brake performance can be improved, and noise and vibrations during braking can be reduced. It is a common automotive repair equipment widely employed in auto repair shops, car maintenance centers, and specialized brake system repair facilities. Operating a brake lathe requires some level of experience and technical knowledge, although the process itself is relatively straightforward. Operators should adhere to safety protocols and ensure proper machine setup and adjustment to achieve high-quality and accurate repair results.

In summary, a Brake lathe machine is a professional equipment used to repair and restore the surface of automotive brake discs, enhancing braking performance and safety. It plays a crucial role in the automotive repair industry and is extensively utilized. It is akin to a wheel repair lathe for car brakes.

What Configurations Does A Brake Lathe Have?

A brake lathe is a specialized machine used for repairing and restoring the surface of automotive brake discs. It consists of several essential configurations, including a lathe machine, cutting tools, grinding wheels, adapters, feed mechanism, clamping system, control panel, cooling system, and collection system.

The lathe machine rotates the brake disc during the repair process, while the cutting tools and grinding wheels are utilized to remove material and improve the surface smoothness. Adapters are included to accommodate different sizes and types of brake discs, ensuring versatility. The feed mechanism enables precise and controlled material removal, while the clamping system securely holds the brake disc in place during the lathe operation. A user-friendly control panel allows for convenient operation and parameter adjustments.

To prevent overheating and damage, a cooling system is incorporated to cool and lubricate the cutting area. Additionally, a collection system is implemented to gather and dispose of the generated debris and waste, maintaining a clean working environment. These configurations ensure that the brake lathe machine is efficient and versatile for different disc sizes and types.

What Are The Characteristics Of The Brake Lathe Produced By HAUSHU Company?

The brake lathe produced by HAUSHU company has several distinctive features that make it stand out in terms of quality, efficiency, company scale, packaging, transportation, warranty, and service.

Quality: The brake lathe manufactured by HAUSHU company is known for its exceptional quality. It is built using advanced manufacturing processes and high-quality materials, ensuring stability and durability.

Efficiency: This brake lathe incorporates advanced technology and design, enabling efficient repair capabilities. It can swiftly and accurately address surface issues on brake discs, enhancing repair efficiency.

Company Scale: HAUSHU company is a large-scale manufacturer equipped with state-of-the-art production facilities and a skilled technical team. This allows for mass production and supply of Brake drum lathe tool to meet market demands.

Packaging: HAUSHU company utilizes professional packaging materials and methods to ensure the safe transportation of their products. The Brake lathe equipment is carefully packaged to protect it from damage and collisions during shipping.

Transportation: HAUSHU company works with reliable logistics partners to ensure secure and timely delivery of the brake lathe to designated customer locations, guaranteeing on-time product arrival.

Warranty: HAUSHU company provides comprehensive quality assurance for their Brake drum repair lathe. The product comes with a specified warranty period, during which any quality issues will be addressed through repair or replacement services.

Service: HAUSHU company places great emphasis on customer service. They offer professional pre-sales consultations and post-sales support, addressing customer inquiries and providing technical guidance. Customer satisfaction is at the core of their service approach, striving to deliver a premium service experience.

In summary, the brake lathe produced by HAUSHU company is renowned for its high-quality construction, efficient repair capabilities, large-scale production capacity, secure packaging and transportation, comprehensive warranty policies, and dedicated customer service. These factors contribute to its widespread recognition and popularity among customers in the market.

How Does A Brake Lathe Compare To A Wheel Repair Machine?

When comparing a brake lathe to a wheel repair machine or wheel CNC machine, it’s essential to understand their distinct roles. While a Commercial brake lathe focuses on resurfacing brake discs to eliminate vibrations and noise, a wheel repair lathe or wheel CNC machine is designed to address and repair wheel imperfections, such as scratches, dents, and deformations. Both machines enhance vehicle performance and safety but operate on different components. A brake drum repair lathe, specifically, targets the drum brakes, ensuring they meet optimal standards.

By understanding these nuances, automotive repair shops can invest in the right equipment to serve their specific needs, ensuring comprehensive vehicle maintenance and customer satisfaction.