1. What Is The Process Like For Australian Customers To Purchase The China Wheel CNC Lathe?

The CK6180W China Wheel CNC lathe manufactured by our company is a highly mature and sought-after product in the market. It has gained widespread popularity and is extensively utilized in various automotive 4S shops, wheel repair shops, and similar establishments. The wheel CNC machine provides exceptional solutions for alloy automobile wheel machining, super-finishing, and maintenance requirements. With its outstanding features of high quality, precision, and efficiency, it has become the preferred choice for professionals in the industry.

Our wheel repair lathe is not only suitable for automobile wheel factories but also finds applications in repair shops. The same goes for our wheel repair machine and brake drum lathe, which are highly regarded for their performance and reliability. We have established strong partnerships with renowned brands from European countries, the United States, South Korea, Russia, and across Asia.

Recently, we had the pleasure of assisting Joe, an Australian reseller, who needed a wheel repair lathe for his customers. After exploring our product range online, he found our company and reached out to us. Considering his requirement for a maximum wheel size of 24 inches, we recommended the CK6180A Wheel lathe machine and CK6180W wheel repair lathe. Both models were suitable for his needs, but Joe expressed a preference for the CK6180W with a laser probe.

We promptly initiated the production process and within a span of 20 days, we successfully manufactured the CNC wheel repair lathe tailored to Joe’s specifications. This collaboration marks the beginning of a promising partnership, and we are confident that if Joe’s customers are satisfied with the machine, we will receive additional orders for our CNC wheel repair lathe.

At our company, we are committed to delivering high-quality products, exceptional customer service, and innovative solutions for the automotive industry. We take pride in our extensive experience, advanced technology, and comprehensive capabilities to meet the diverse needs of our clients. Whether it’s alloy wheel machining, super-finishing, or maintenance, our CK6180W Wheel CNC lathe is designed to exceed expectations and deliver superior results.

2. What Are The Characteristics Of The HAISHU China Wheel CNC Lathe Compared To Traditional Wheel Repair Lathes?

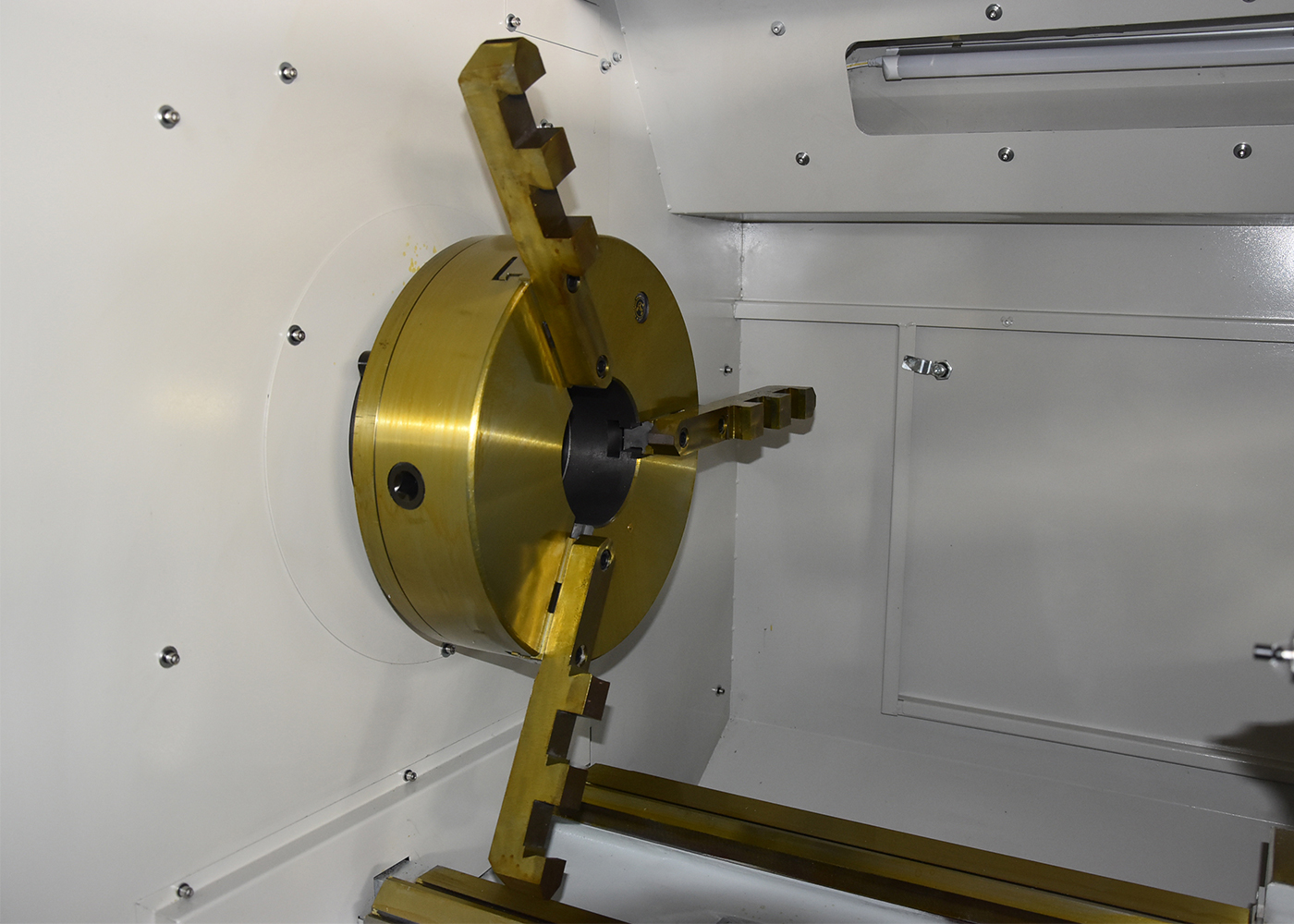

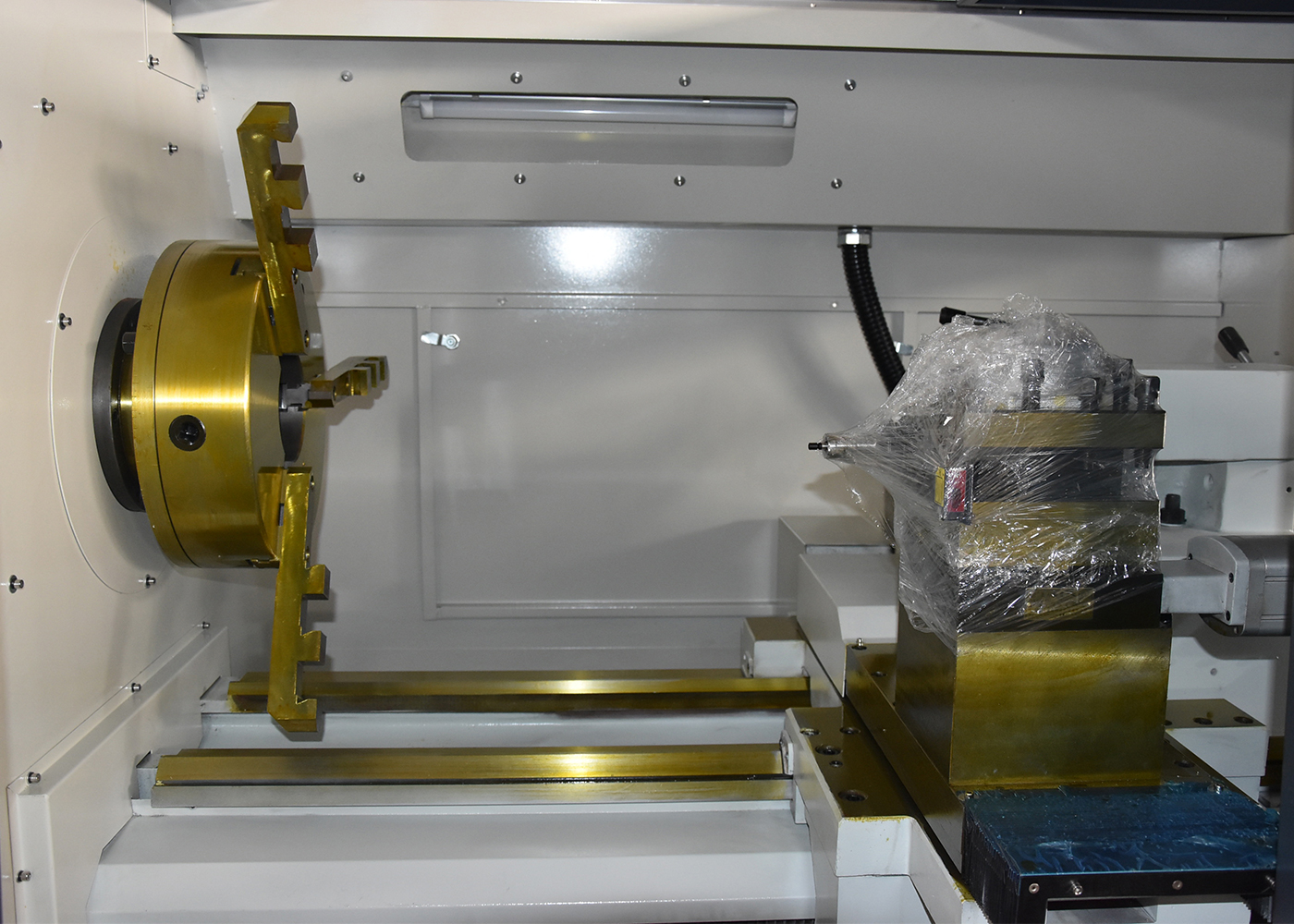

2.1 The CK6180W Wheel CNC Lathe incorporates a fully enclosed sheet metal design, which serves a dual purpose. It aims to prevent aluminum chips from escaping the machine’s confines, ensuring a safe working environment. The enclosed setup promotes cleanliness, reduces noise levels, and enhances overall safety.

2.2 One of the standout features of this wheel CNC lathe is the installation of a dedicated CNC system, equipped with software specifically designed for automotive wheel hubs. This specialized software has significantly improved efficiency and precision compared to traditional operating systems. In the past, generating wheel hub programs required manual programming, which was time-consuming and prone to errors. With the CK6180W’s dedicated system, a single click is all it takes to generate a machining program with automatic G-code generation.

2.3 Moreover, the CNC wheel lathe’s tool holder is software-controlled and features an automatic rotation function. This enables the tools to rotate automatically, eliminating the need for manual tool changes. As a result, it increases efficiency and facilitates operator control.

2.4 An additional noteworthy aspect is the user-friendly operation of the advanced wheel repair lathe. Its fully automated one-click functionality significantly reduces the learning curve, making it easily accessible even for beginners. Traditional alloy wheel lathes tend to be more challenging to learn, resulting in higher learning costs and operational difficulties. HAISHU’s wheel repair lathe can be mastered in as little as 30 minutes, ensuring users have a pleasant operational experience and an enjoyable learning process.

2.5 Furthermore, HAISHU’s wheel repair lathe offers various options for wheel hub detection. Unlike older models that solely rely on mechanical probing, our lathe provides three detection methods: laser detection, mechanical probe detection, and tool tip detection. Customers can choose their preferred detection method or even combine all three functionalities.

2.6 In summary, the CK6180W Wheel CNC Lathe by HAISHU features a fully enclosed design, specialized CNC system, automated tool rotation, user-friendly operation, and multiple wheel hub detection options. These comprehensive features provide customers with enhanced safety, efficiency, precision, and flexibility for their wheel repair and machining needs.

3. The Other Side Of HAISHU That You Can’t Imagine

HAISHU’s Wheel CNC Lathe stands out from traditional wheel repair lathes due to its unique characteristics and dedicated design team. Our team consists of 19 designers, 8 electrical engineers, and 4 quality inspectors who collaborate to create exceptional wheel repair machines. In addition to our standard designs, we offer customized solutions tailored to meet the specific requirements of our customers.

When it comes to customization, HAISHU goes the extra mile. We provide options for customizing the appearance, system logos, software functionality, language preferences, working voltage, diverse fixture options, tool holder variations, and even the type of machine guard door switch, such as pneumatic opening. We can also extend the travel range of each axis based on individual needs. Our goal is to ensure that customers receive a CNC wheel repair lathe that fully satisfies their unique specifications.

At HAISHU, we welcome inquiries and strive to provide the best possible solutions within our capabilities. Whether you need a customized CNC wheel repair lathe or have specific requirements, our experienced team is ready to assist you. Contact us today to discuss your needs and benefit from our expertise in the field of wheel repair lathe manufacturing.