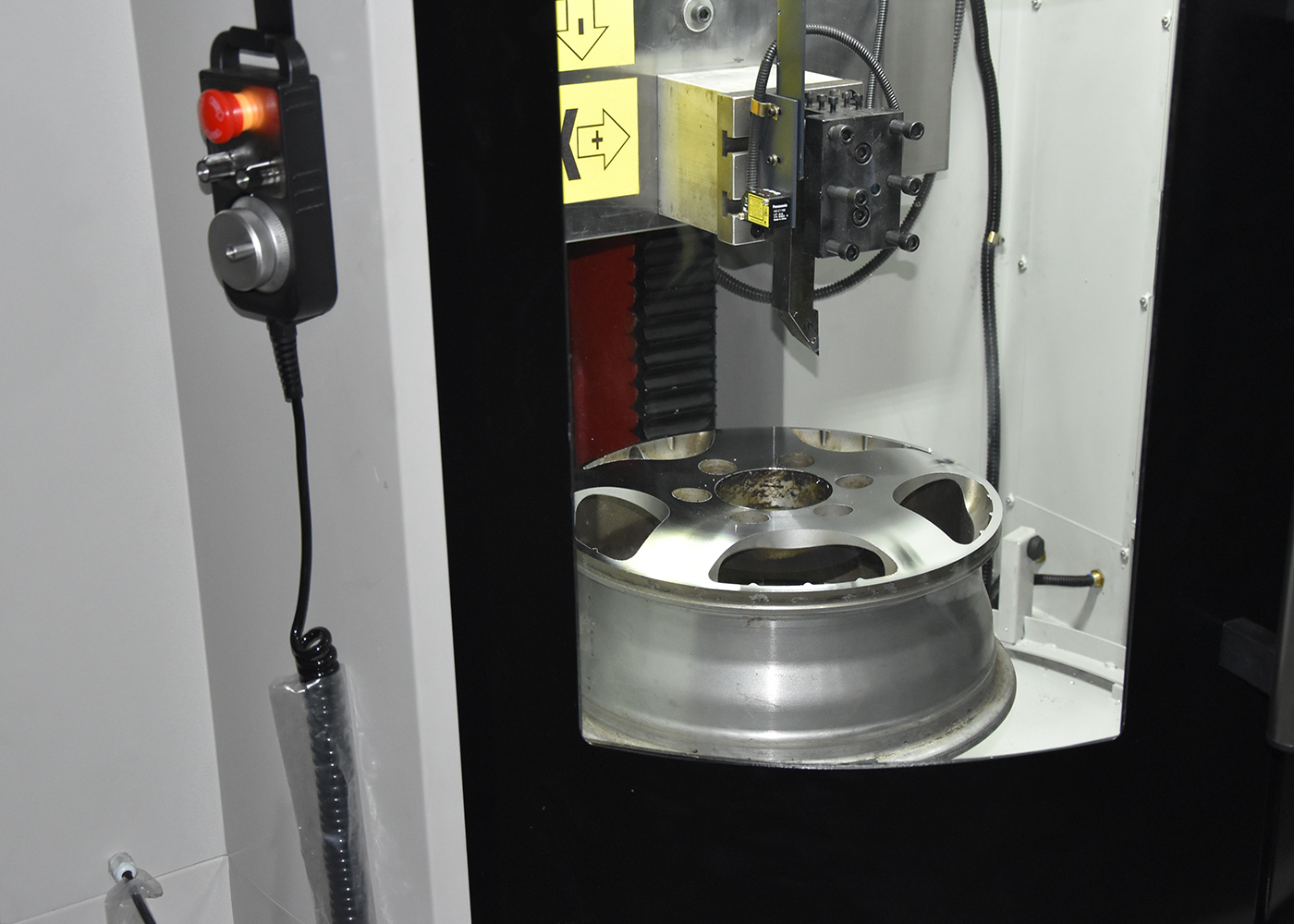

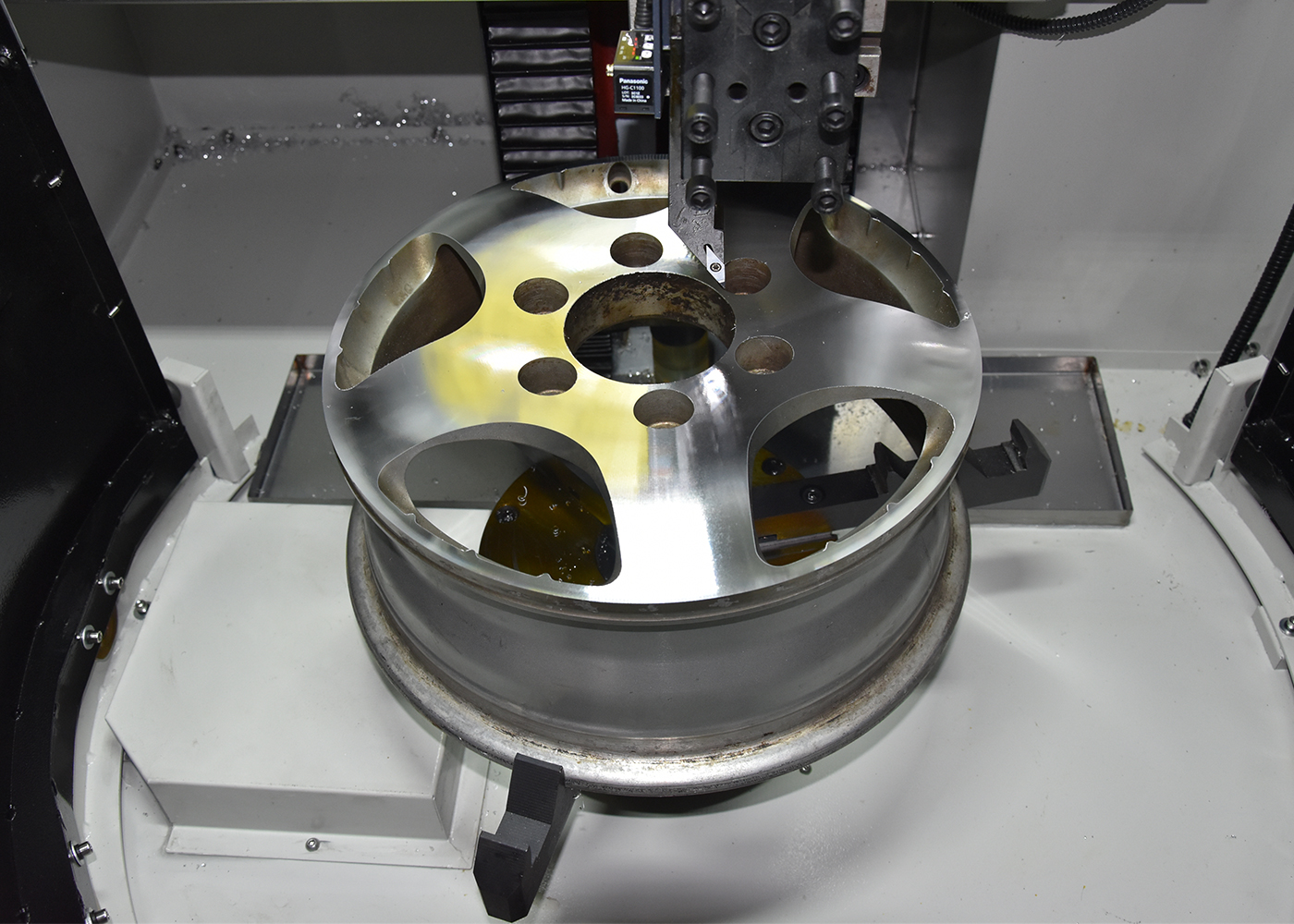

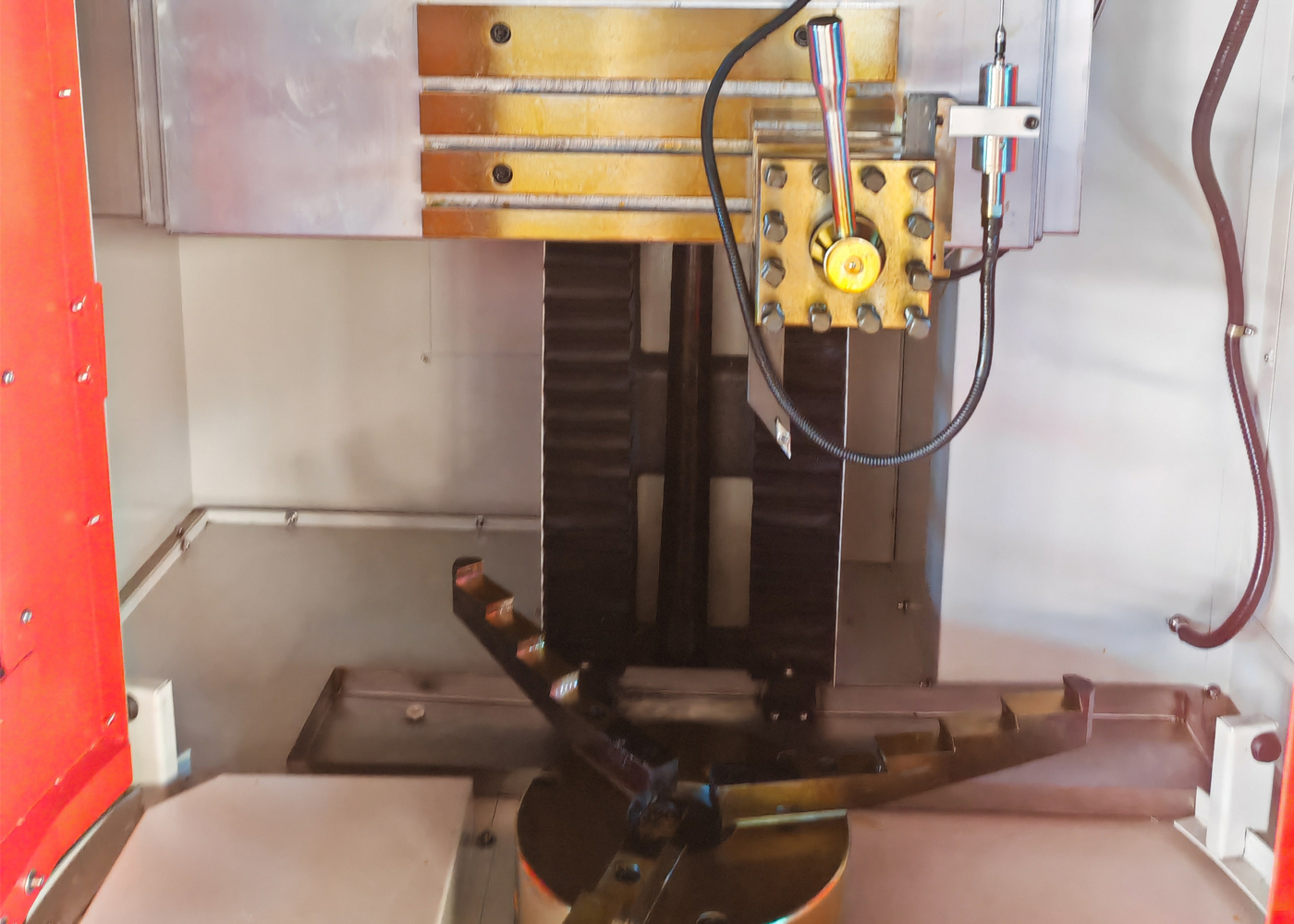

When it comes to selecting the perfect wheel repair lathe toolpost for your automotive service center, it’s crucial to understand the differences between the available toolpost options. A wheel repair machine, especially a wheel CNC machine, is indispensable for addressing the wear and tear on vehicle rims that result from challenging driving conditions. These versatile machines, equipped with laser detection and CNC technology, can adeptly restore damaged wheels to their former glory.

In the world of wheel refurbishment, two prominent contenders are the vertical wheel repair lathe and the manual wheel repair lathe. Each brings unique benefits and limitations to the table. Below, we will delve into the advantages and drawbacks of the direct (vertical) toolpost and the manual toolpost.

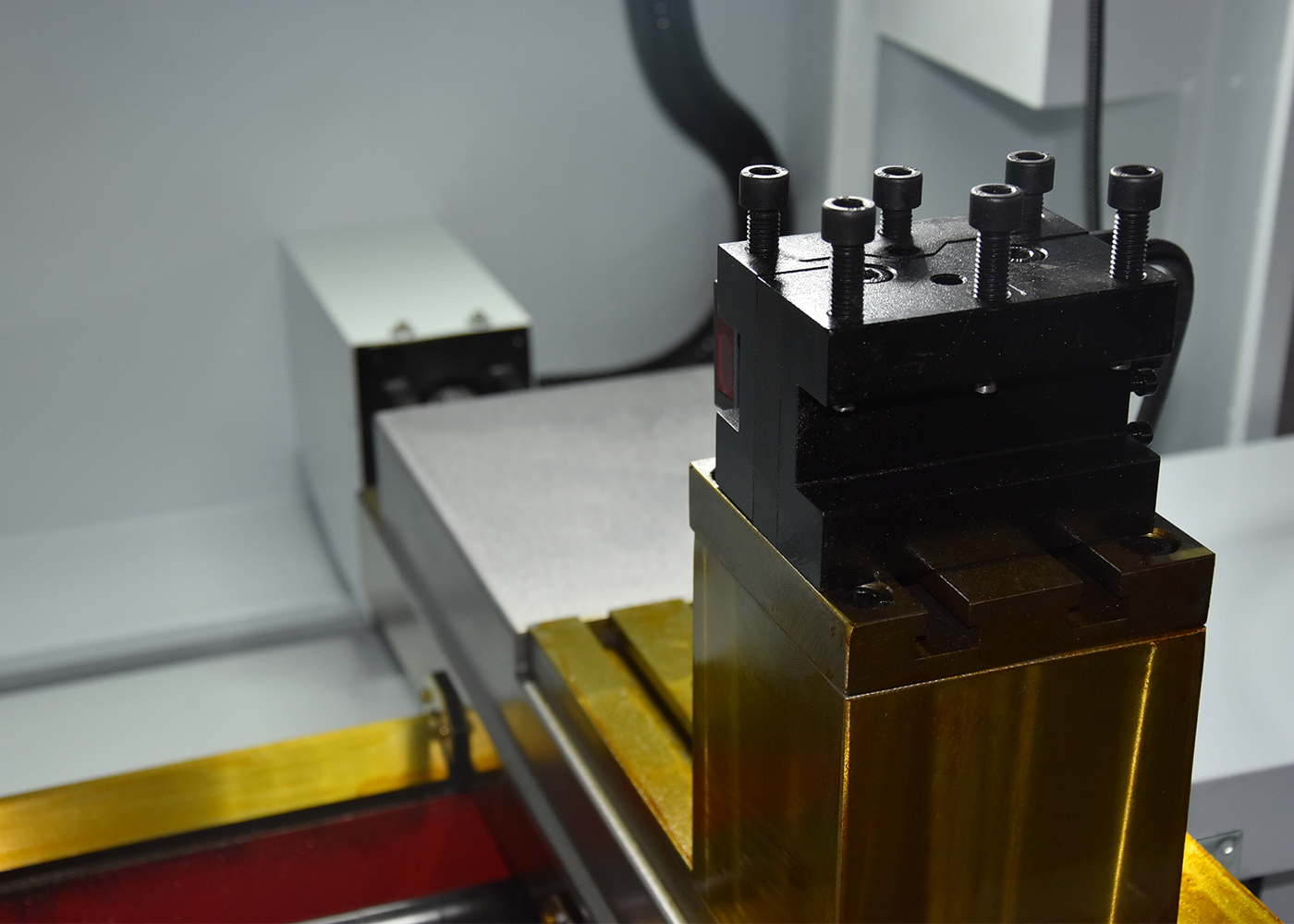

Advantages of a Vertical Wheel Repair Lathe Toolpost

Rapid Tool Changes: The vertical wheel repair lathe allows for quick tool changes, significantly reducing downtime and boosting productivity. This feature is a game-changer in high-volume shops where efficiency is paramount.

Stability and Precision: Engineered to minimize vibrations, the vertical toolpost enhances overall machining precision, a critical factor in achieving flawless wheel finishes.

Rigidity: Its robust design is ideal for heavy cutting operations, ensuring the wheel CNC lathe operates under optimal conditions even under demanding tasks.

Maintenance: With a simple structure, the vertical wheel repair lathe tool demands minimal maintenance, saving both time and resources in the long run.

Space Efficiency: The compact design is compatible with a variety of wheel sizes, making it a versatile solution for shops with limited space.

Adaptability and Flexibility: Capable of accommodating multiple cutting tools, the vertical toolpost is adaptable to various machining requirements.

Thermal Expansion: Reduced thermal expansion effects mean more consistent work throughout the repair process.

Cost-Effectiveness: The initial investment and operating costs are relatively low, offering a high return on investment.

Limitations of a Vertical Wheel Repair Lathe Toolpost

Tool Capacity: A vertical toolpost’s setup may not support a vast array of tools, which could be a limitation for complex repair tasks.

Automation: With limited support for automatic tool selection, efficiency could be impacted, especially for custom wheel repairs.

Tool Interference: The potential for tool conflicts can arise, necessitating careful planning of the machining process.

Extreme Cutting Conditions: Under severe cutting conditions, the performance of the vertical toolpost might be constrained.

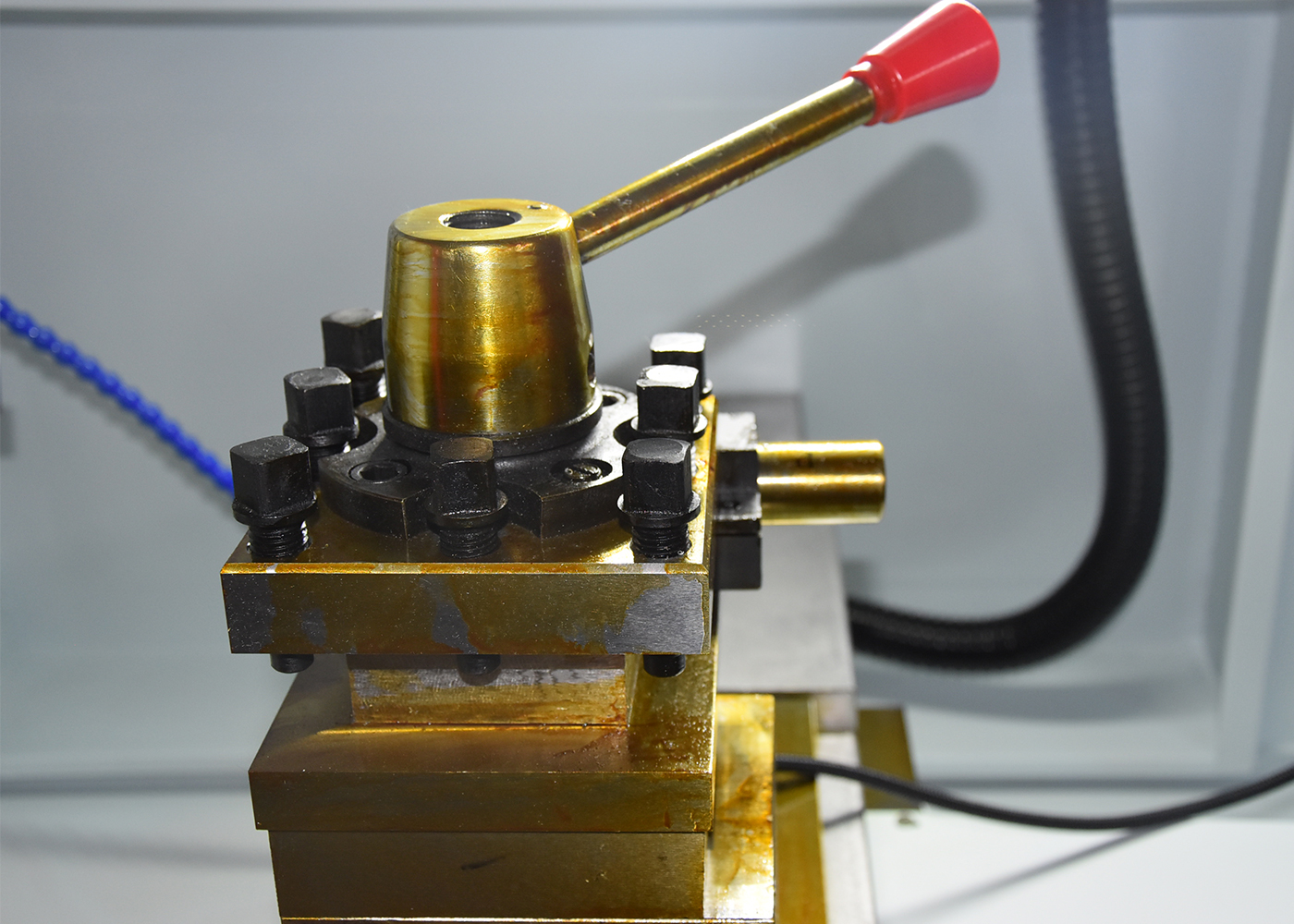

Advantages of a Manual Wheel Repair Lathe Toolpost

Cost Savings: For businesses on a tight budget, the manual toolpost is an economical option, making it accessible for startup wheel repair services.

Ease of Operation: The manual wheel repair lathe is straightforward to use and ideal for operators who are in the process of learning the trade.

Maintenance Simplicity: With fewer complex parts, maintenance is a breeze, and costs are kept to a minimum.

Small Batch Production: The manual toolpost can be quickly adapted to different tasks, perfect for custom wheel repair jobs.

Error Detection: Operators can easily detect and correct issues on the fly, which is invaluable for ensuring high-quality finishes.

Limitations of a Manual Wheel Repair Lathe Toolpost

Efficiency: Tool changes are time-consuming, which can be a significant disadvantage in a busy wheel repair shop.

Consistency and Precision: The potential for human error can affect the uniformity and accuracy of the wheel repairs.

Labor Intensity: High labor demands can lead to operator fatigue, impacting overall productivity.

Safety Risks: Manual changes increase the risk of injury, which is a concern for any workshop.

Complex Tasks: For intricate wheel repair jobs, manual tool changes can prolong the process, leading to inefficiencies.

Automation Level: The lower level of automation may hinder the ability to scale up production or introduce more advanced machining techniques.

After evaluating the needs of a wheel repair lathe, it becomes clear that the direct (vertical) toolpost stands out for its simplicity, ease of operation, high repeatability, robustness, space adaptability, and versatility. It’s an excellent fit for various wheel repair tasks, offering the flexibility to use cutting tools from different angles, with the toolpost serving merely as a stable platform. Thus, for distributors or end-users, the vertical wheel repair lathe tools often emerge as the superior choice.

Whether you’re in the market for a mobile wheel repair lathe or a stationary setup, the vertical toolpost should be at the top of your considerations. It’s not just about having a machine that can do the job, but having one that can do it efficiently, reliably, and with the precision that today’s discerning customers expect.

For those seeking to enhance their wheel repair services with the latest in wheel CNC technology, the vertical wheel repair lathe tools offer a blend of performance and value that’s hard to beat. Investing in a wheel CNC lathe with a vertical toolpost is a strategic move that can help streamline operations, reduce turnaround times, and deliver exceptional quality that keeps customers coming back.

In conclusion, while both vertical and manual toolposts have their respective places in the wheel repair industry, it’s the vertical wheel repair lathe toolpost that often provides the best balance of efficiency, precision, and cost-effectiveness.