What Does The Customized Wheel Repair Machine For The Vietnamese Customer Look like?

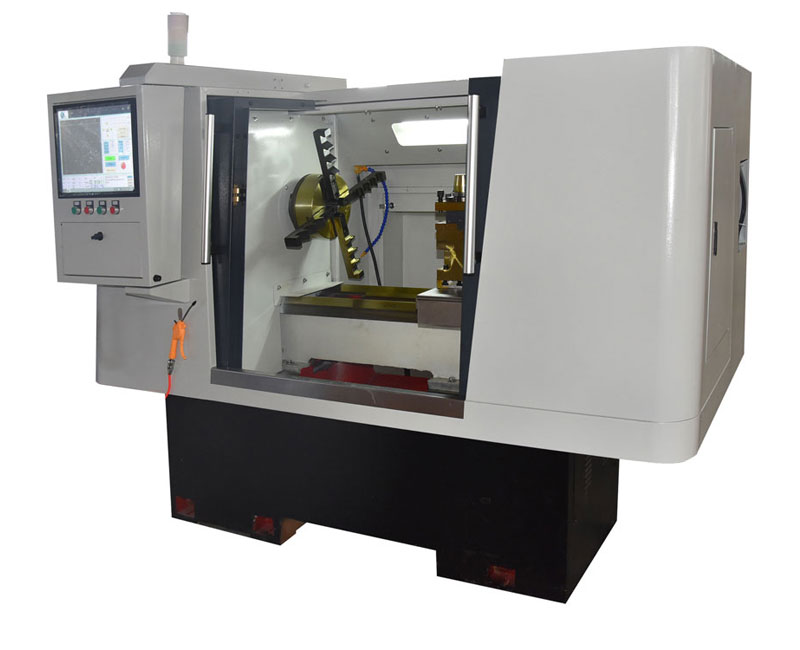

The CK6160W Custom Wheel Repair Machine has established itself as the premier CNC wheel lathe in the rim repair industry since its introduction in 2000. With its unparalleled features and performance, it has become the go-to choice for professionals worldwide. Equipped with a user-friendly touchscreen control system, our wheel repair lathe offers a seamless and effortless operation experience. The self-developed unique systems and dedicated “HSAISHU” software specifically designed for wheel lathes further enhance its capabilities.

Our extensive global presence is evidenced by our agents in over 30 countries. The majority of professional rim shops rely on our wheel CNC lathes due to their exceptional quality and superior performance. The CK6160W guarantees to replicate or even surpass the factory-quality finishes on rims, ensuring impeccable results every time.

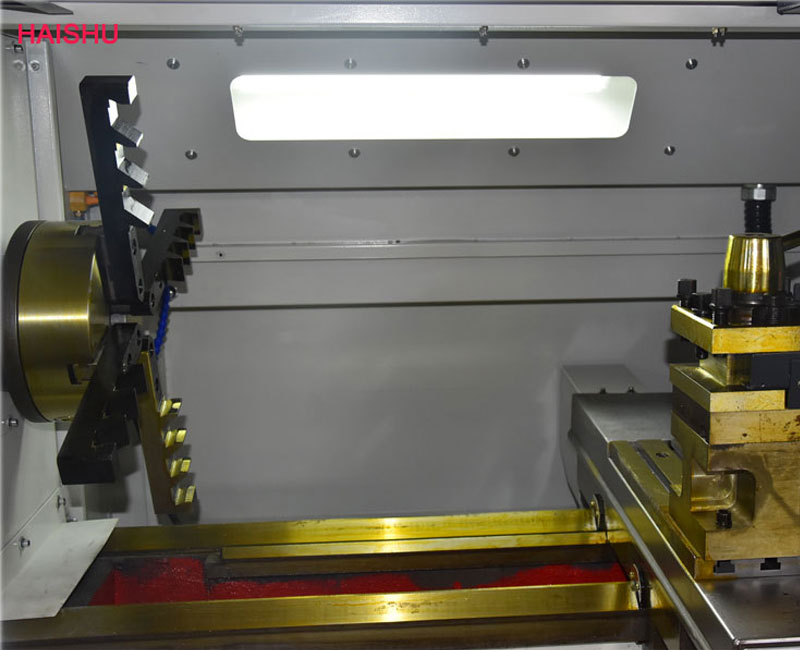

One of our valued customers in Vietnam has already procured multiple Alloy Wheel Repair Equipment from us. This time, they required a customized wheel CNC lathe to cater to their special wheels. Upon confirming the maximum wheel size and thickness, we recommended the Alloy Wheels Lathe CK6160W and offered to customize and extend the Z-axis travel to accommodate their specific requirements. Our prompt and effective solution to their long-standing problem left them immensely grateful, prompting them to express their desire to immediately pay the deposit. We promptly provided them with the Proforma Invoice (PI) and initiated the preparations for their customized CK6160W Custom Wheel Repair Machine.

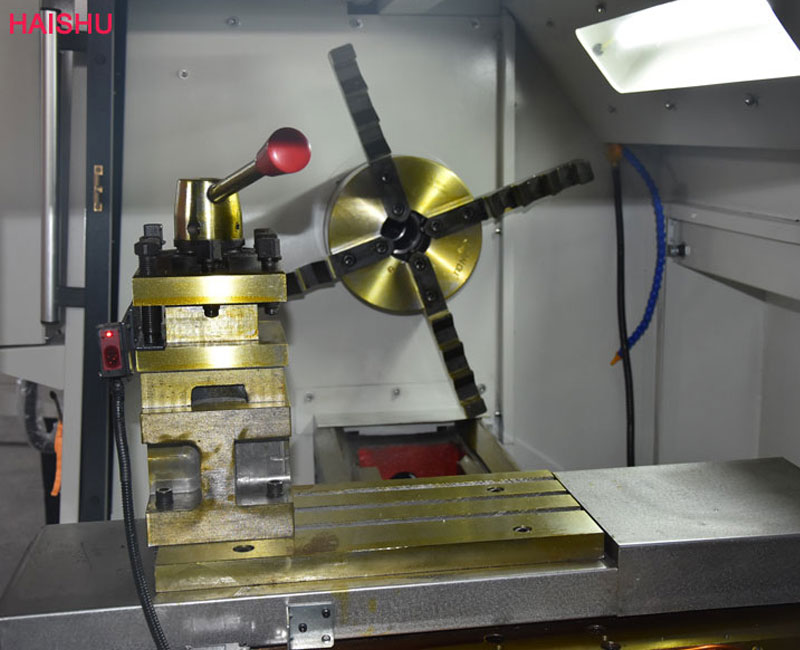

Upon the completion of the Diamond Cutting process, the Alloy Wheels Lathe CK6160W was ready for use. To ensure complete customer satisfaction, we shared a comprehensive test video and detailed pictures showcasing the capabilities of the Alloy Wheel Surface Repair lathe. The customer was highly content with the results, further solidifying their confidence in our products and services.

With the CK6160W Custom Wheel Repair Machine, we continue to deliver unmatched quality, performance, and customer satisfaction. Our commitment to innovation and excellence remains unwavering as we strive to meet the evolving needs of the rim repair industry.

Custom Wheel Repair Machine CK6160W Specifications

| Item | Unit | Specifications |

| Max Wheel Diameter | inch | 22″ |

| X-axis maximum stroke | mm | 320 |

| Main motor power | kw | 3 |

| Rial Width | mm | 260 |

| Max. workpiece length | mm | 500 |

| Wheel measuring direction | X, Z | |

| Measuring Tool | Laser or probe (optional) | |

| Measurement method | Point measurement and a quick scan | |

| Program optimization | Manual and automatic | |

| Number of wheel processing programs | rows | 100000 |

| CNC System | “HAISHU” special system (touch screen operation, 17 “screen LCD display).

Universal CNC system (key operation, 10.4 “screen LCD display) (optional) |

|

| Wheel processing | Surface, rim | |

| Machining accuracy | um | IT6~IT7 |

| Main drive form | Frequency control, servo drive (optional) | |

| Spindle speed | Factory setting 150~2800 | |

| Fast-moving feed | mm/min | X:5000 Z:8000 |

| Repeat accuracy | mm | X :0.01 Z :0.015 |

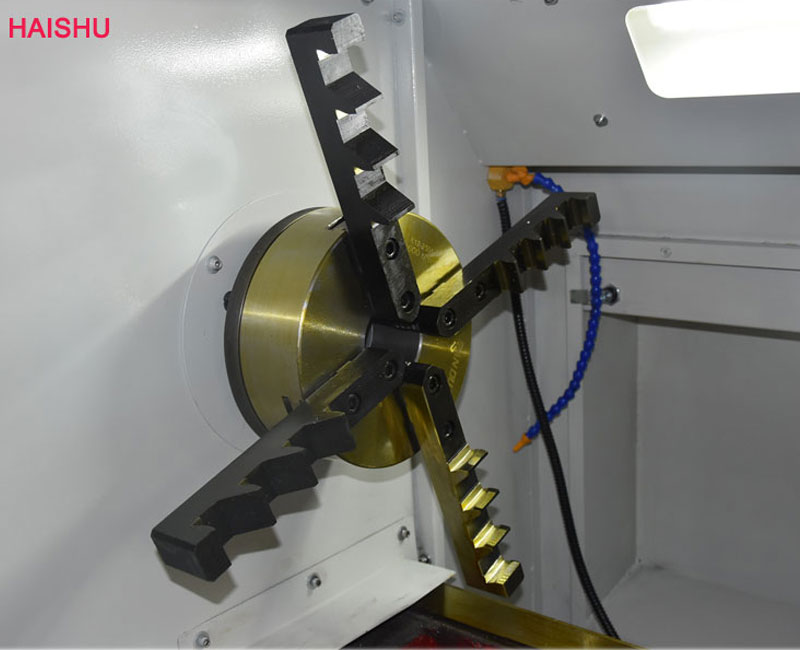

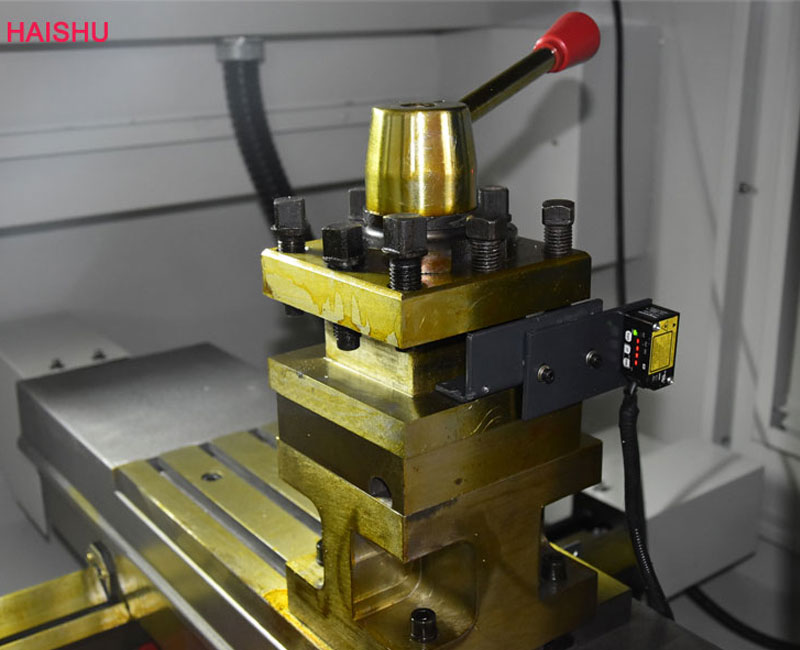

| Turret form | Fixed turret,Electric turret (optional) | |

| Section of the turning tool | mm | 25×25 |

| Machine size(L×W×H) | mm | 1900×1400×1750 |

| Net weight | kg | 1300 |

What Is The Features Of The Customized Wheel Repair Machine?

The CK6160W Custom Wheel Repair Machine boasts a range of impressive features that make it a top choice in the industry.

- The machine’s simple structure, cost-effectiveness, and high-performance price ratio set it apart from the competition.

- The Diamond Cut Wheel lathe offers flexibility in measurement options, allowing users to choose between laser scanning or probe click measurement.

- Wheel data is automatically stored, and machining programs can be easily recalled as needed.

- The software is independently developed, enabling automatic optimization of machining programs.

- The wheel processing is highly precise and fast, ensuring efficient operations.

- The machine is operated through a user-friendly touch screen, and the system interface supports multiple languages for enhanced accessibility.

- The X/Z-axis measurement allows for precise machining of the wheel surface and circumferential areas.

- An automatic lubrication system is integrated into the machine, ensuring smooth and reliable operation.

- The Wheel CNC Machine utilizes diamond tool turning, resulting in a smoother surface finish for the wheels.

- The machine features a teaching function that allows for easy programming and customization using a computer interface.

- The Wheel Surface Repair lathe can be tailored to meet specific customer requirements, providing a customizable solution for various wheel repair needs.

With its advanced features and customizable options, the CK6160W Custom Wheel Repair Machine offers a comprehensive solution for the rim repair industry, ensuring high-quality results and customer satisfaction.

Our Alloy Wheel Repair Machines are known for their high-tech features, professional performance, and top-notch quality. They are widely used by professional rim shops worldwide, as well as reputable automobile and wheel manufacturers. Whether you are looking to start an alloy wheel repair business or need to repair and refurbish damaged machined/polished alloy wheels, we have the perfect solution for you. Please don’t hesitate to contact us, and we will provide you with an amazing alloy wheel lathe that meets your needs and exceeds your expectations.