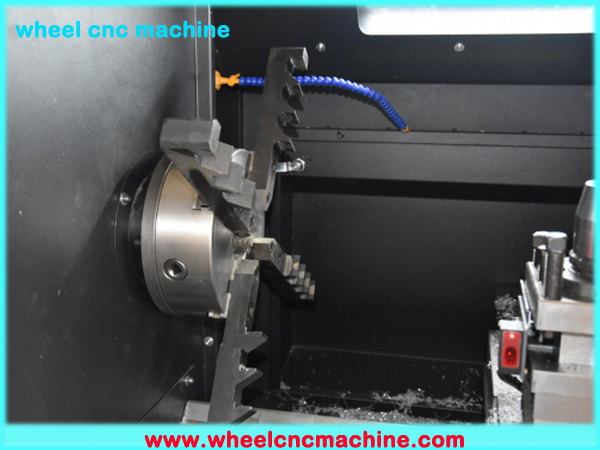

Diamond Cutting Alloy Wheels Lathe CK6160W is designed with black appearance and fully covered by sheet metal shell. The wheel CNC lathe CK6160W has a good protective effect and a beautiful appearance. At the same time, Wheel Lathe CK6160W has such key benefits as max wheel process up to 24 inches in diameter, fully automated and easy to use, PC based interface controller, easy to use touchscreen interface, Automated optimization, laser detection can probe a normal wheel in 1 minute, Compact design saves on workshop space. Option configuration can be customized.

This Russian customer has a 4s shop and wants to purchase an automatic lathe for repairing the wheel. After confirming the max wheel size, we chose Diamond Cutting Alloy Wheels Lathe CK6160W. After they saw the parameter and machine operate video of Alloy Wheel Surface Repair lathe CK6160W, they were very satisfied and wanted to order 1 set. We sent the PI to them and they paid the deposit.

After the Diamond Cutting, Alloy Wheels Lathe CK6160W completed, we sent them the Alloy Wheel Surface Repair lathe test video and detailed pictures. He was very satisfied.

Diamond Cutting Alloy Wheels Lathe CK6160W Specifications

| Item | Unit | Specifications |

|---|---|---|

| Max Wheel Diameter | inch | 24″ |

| Main motor power | Kw | 3 |

| Wheel measuring direction | X,Z | |

| Measuring Tool | Laser or probe (optional) | |

| CNC System | “HAISHU” special system (touch screen operation, 17 “screen LCD display).

Universal CNC system (key operation, 10.4 “screen LCD display) (optional) |

|

| Section of turning tool | mm | 25×25 |

| Machine size(L×W×H) | mm | 1900×1400×1750 |

| Net weight | Kg | 1300 |

Diamond Cutting Alloy Wheels Lathe CK6160W Features

1. The Wheel Machine has the advantages of simple structure, low cost, and high-performance price ratio.

2. The Diamond Cut Wheel lathe can be selected by laser scanning or probe click measurement.

3. Wheel data is automatically stored, the machining program is arbitrarily called out.

4. Software independent development, program automatically optimize.

5. Wheel processing is automatic precise and fast.

6. The wheel CNC lathe is operated by a touch screen, and the system interface supports many languages.

7.X / Z-axis measurement, wheel surface, and circumferential machining.

8. The wheel repair Machine is equipped with an automatic lubrication system.

9. The Wheel CNC Machine with diamond tool turning, make wheel surface more smooth.

10. The Alloy Wheel Surface Repair lathe machine has the teaching function of the computer.

11. The Alloy Wheel Surface Repair lathe can be customized according to customer requirements.

About Haishu Machinery

Haishu Machinery is a modern professional company specialized in R&D, manufacturing, sales, technical training, and import trade of automotive Diamond Cutting Alloy Wheels Lathe. We have the latest(state-of-the-art) technology for diamond cutting alloy wheels.

If you want a lathe which is good for an alloy wheel repair business, to start up an alloy wheel repair business, or to repair and refurbish damaged machined/polished alloy wheels; We offer an amazing alloy wheel lathe that delivers great value with decent price while still offering the most amazing finishes on your wheels. As of now, the majority of new cars come with alloy wheels as standard, the options available are growing and diamond cut wheels are becoming more popular. With this growing market, there is an increasing demand for diamond cut wheel repairs, our wheel lathe is a great choice for you to be able to tap into this growing market of alloy wheel refurbishment. Our wheel turning lathe is the lathe to use if you are serious about offering alloy wheel repair and refurbishment services.