Essential Hub Repair: A Guide to Safety and Precision

Introduction to Hub Maintenance

Hub repair is a critical component of vehicular maintenance, involving the careful restoration of a vehicle’s wheel hubs. This guide aims to inform vehicle owners and service technicians about the importance of hub repair, the use of specialized machinery such as a wheel repair lathe, and the crucial decisions between hub repair and replacement.

Significance of Hub Repair

Ensuring Vehicle Safety

Vehicle safety is closely linked to the integrity of the hubs. Minor damage such as scratches can escalate into more significant issues if ignored. Rim repair equipment offers a non-invasive fix that preserves the structural integrity of the hub. For more severe damage, an alloy wheel repair machine is necessary to restore proper functionality. If a hub is extensively damaged, replacement might be the safer alternative to repair.

Understanding Wheel Performance

Hubs, often made from aluminum alloy, are prone to metal fatigue. Damage left unrepaired can compromise wheel performance and driving safety. A CNC wheel lathe can address these issues promptly. For professionals, vertical wheel repair lathes and alloy wheel lathes are essential for delivering precision and dependability.

Hub Repair Strategies and Tools

Selecting the Appropriate Repair Approach

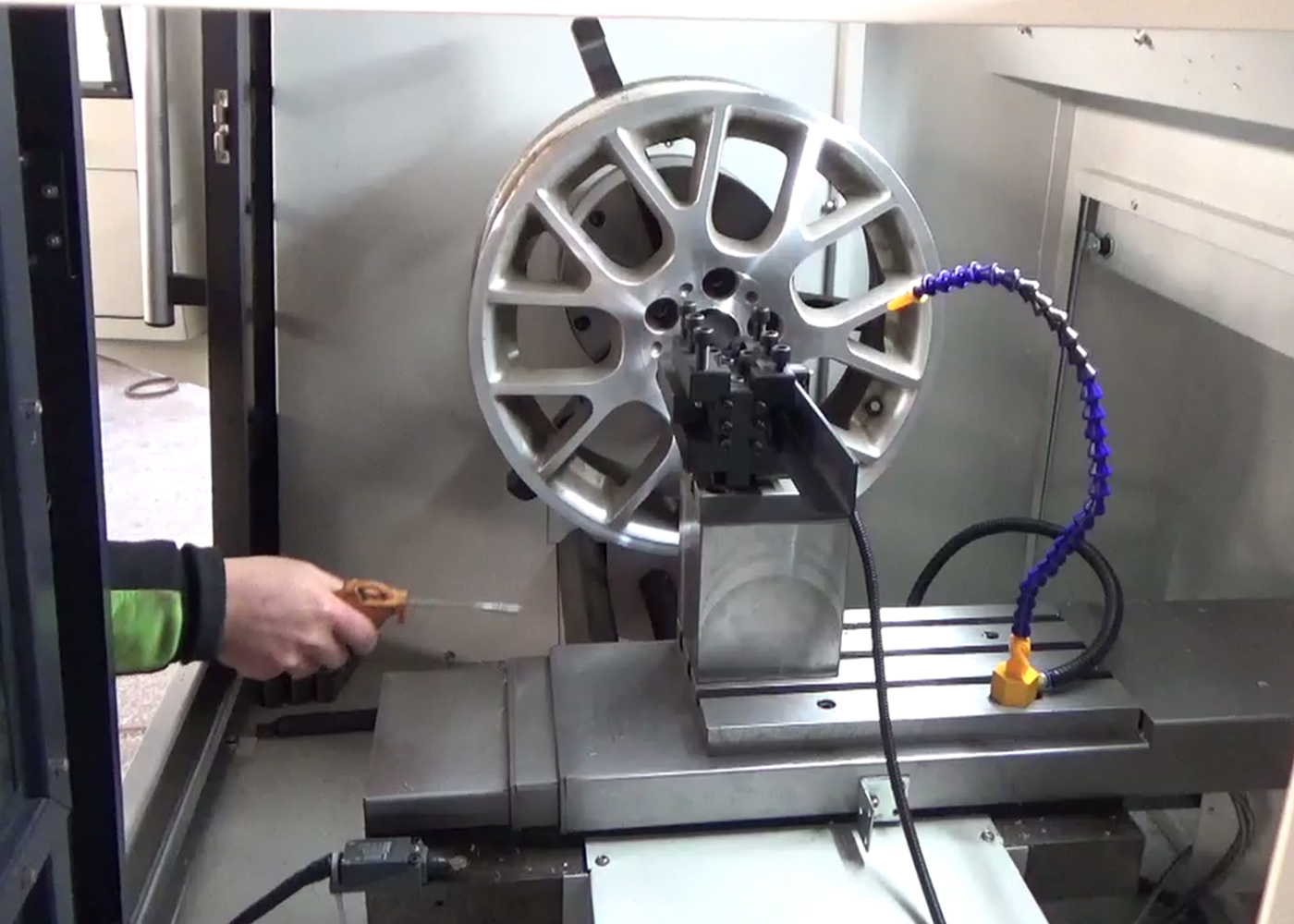

For minor hub damage, a rim refurbishment machine can quickly restore the wheel’s appearance. More significant damage requires a wheel CNC machine or a mobile wheel repair lathe, which assures both aesthetic and structural integrity. A diamond cutting wheel lathe can provide a polished finish, especially critical for hubs with intricate designs.

Innovative Repair Machinery

Professionals seeking top-quality results should consider automated wheel repair machines or wheel restoration machines. These pieces of equipment offer the precision needed for complex repairs that could require an alloy wheel diamond-cutting machine. A rim straightening machine is indispensable for correcting bent rims, ensuring the wheel rolls smoothly.

The Hub Repair Methodology

Preparing for Effective Repair

The hub repair process starts with careful preparation. Reshaping indented hubs while maintaining the metal’s properties is key. A wheel refinishing machine then smoothens the hub’s surface.

Applying the Finishing Touches

After the repair, the hub is ready for finishing. A wheel polishing machine creates a smooth base for the paint. The hub is painted with a color that closely matches the original, achieved with an automated paint system.

The Case for Nitrogen in Tires

The debate about using nitrogen or air in tires is ongoing. Nitrogen has certain benefits for commercial vehicles due to its stable properties. However, maintaining proper tire pressure is crucial for safety and performance, whether nitrogen or air is used.

Introducing HAISHU

Taian HAISHU is renowned for its quality wheel lathe machines, including vertical wheel hub lathes and mobile wheel CNC lathes. Those in the market for superior hub repair equipment will find HAISHU’s offerings to be of exceptional quality and reliability.

Conclusion

Hub repair is essential for vehicle safety and aesthetics. Using the right tools, such as a wheel repair CNC lathe or an alloy wheel repair machine, is crucial for restoring hubs to their optimal condition. HAISHU’s equipment, including the alloy wheel diamond cutting machine and the rim straightening machine, ensures precision in repair work. Remember, the safety of your vehicle and its passengers should always be the top priority in hub maintenance.