How Do CNC Wheel Machines Transform Traditional Wheel Repair?

Historically, traditional wheel repair depended heavily on the manual skills of technicians using standard CNC lathes. This process required intricate programming and precise manual input of coordinates, leading to a high risk of human error, such as misaligned coordinates and tool crashes. These limitations not only made the process labor-intensive but also restricted the repair capabilities and throughput, affecting the overall efficiency and quality of wheel repairs.

How Do CNC Wheel Machines Enhance Wheel Repair Efficiency?

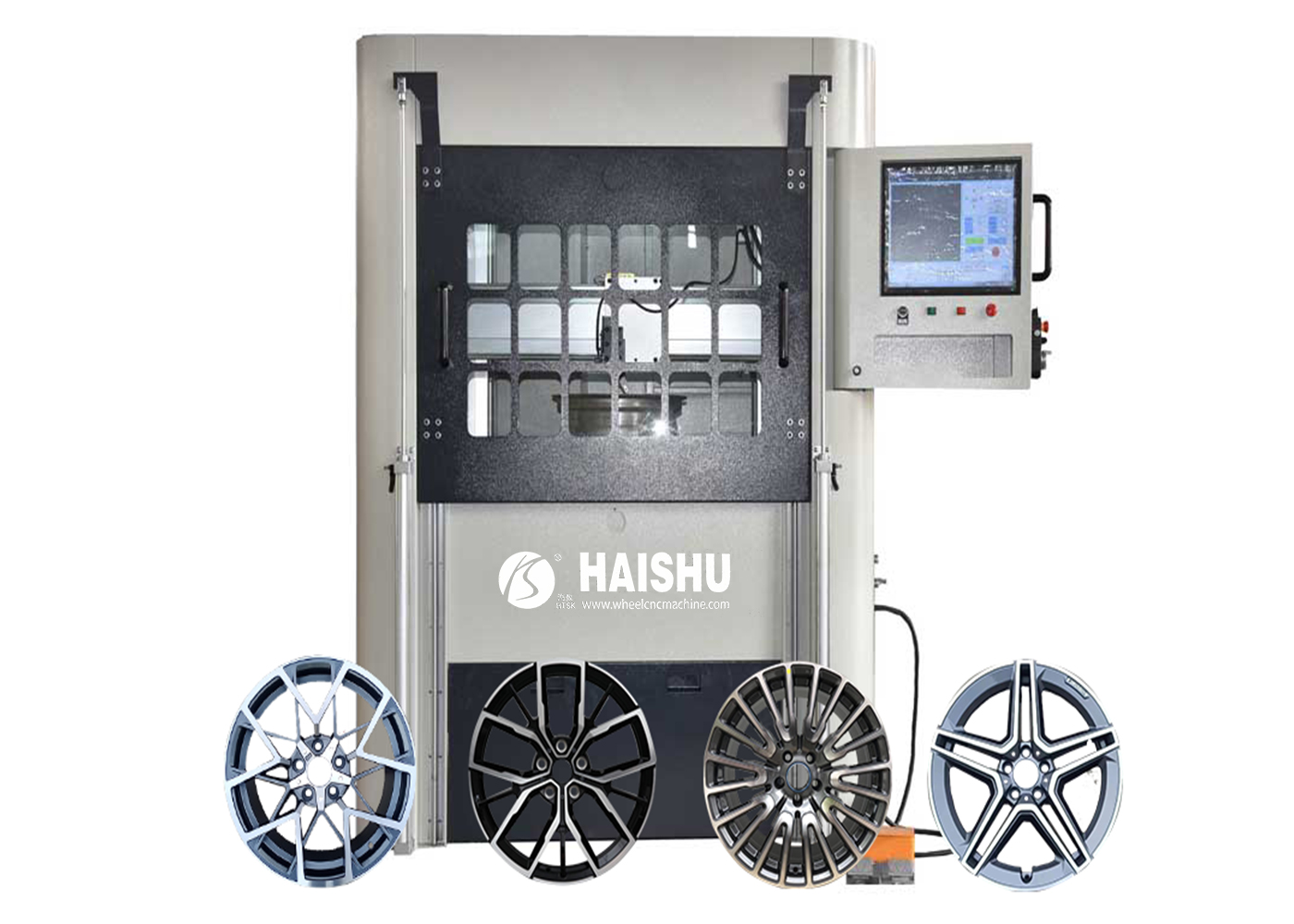

The introduction of CNC Wheel Machines has revolutionized the wheel repair industry by automating and streamlining the repair process. The HAISHU CNC Wheel Lathe, a leader in this innovation, incorporates advanced detection technology and optimization systems that significantly enhance machining efficiency, safety, and precision.

These machines, such as the Tai’an HAISHU CNC Wheel Repair Lathe, integrate features like laser detection, mechanical probing, and tooltip detection, accommodating various automobile wheel types. The process starts with a swift fixture loading followed by a comprehensive laser scan, which collects all necessary data in just 15 seconds—a stark contrast to older methods. This technological advancement not only speeds up the repair process but also ensures high precision with the use of advanced servo motors and precision ball screws, enhancing the quality of the repair and extending the life of the wheels.

Moreover, the HAISHU Wheel CNC Machine can complete a wheel repair in as little as 30 minutes, significantly boosting operational efficiency and reducing costs. The CNC machining programs created can be replicated for similar tasks, ensuring consistency and flexibility in operations.

What Future Trends Will CNC Wheel Machines Introduce to the Industry?

Looking ahead, the wheel repair industry is set to become even more automated and intelligent. Advances are aimed at reducing the skill required to operate these machines, facilitating one-touch operations that promise a future of smart factories with fully automated repair services.

The role of technology in Wheel Repair Machine is pivotal. They not only simplify existing processes but also open avenues for new services and business models. The integration of AI and IoT is expected to further enhance the capabilities of these machines, promoting more sustainable practices by reducing waste and increasing the efficiency of resource use.

In summary, CNC Wheel Machines stand at the forefront of technological evolution in the wheel repair industry. They are setting new standards for efficiency, cost savings, and ease of operation. With ongoing innovations in automation and customization, CNC Wheel Machines are poised to shape the future of wheel repair, meeting the increasing demands of a technologically savvy customer base and expanding globally to new markets. As these machines continue to evolve, they will transform the wheel repair industry, ensuring high-quality, efficient, and customizable wheel repairs.