In the fast-evolving world of automotive repair, precision and efficiency are paramount, especially when it comes to refurbishing alloy wheels. A best wheel repair lathe can transform a shop’s capabilities, turning damaged rims into like-new components with minimal effort. Whether you’re a shop owner seeking to expand services or a technician aiming to streamline operations, choosing the right CNC lathe is a critical decision. The options can be overwhelming, with numerous CNC lathe manufacturers and factories offering advanced solutions.

This comprehensive guide, crafted with expertise from years in the CNC industry, dives deep into selecting the wheel repair machine for your needs. We’ll explore its definition, functions, advantages, disadvantages, and key considerations, spotlighting HAISHU Machinery—a trusted name among CNC lathe manufacturers—for its innovative offerings. By the end, you’ll have the knowledge to invest wisely in equipment that boosts productivity and profitability.

1. What Is the Best Wheel Repair Lathe?

A best wheel repair lathe is a specialized CNC (Computer Numerical Control) machine designed to repair, refurbish, and enhance alloy wheels with exceptional precision. Unlike traditional manual lathes, these advanced tools integrate computerized controls to automate cutting, grinding, and finishing processes. Drawing parallels from CNC dental file grinders—known for their micron-level accuracy in shaping dental tools—a wheel CNC lathe achieves similar precision, restoring wheel surfaces, center holes, and rims to OEM (Original Equipment Manufacturer) standards.

Typically manufactured by leading CNC lathe manufacturers like HAISHU Machinery, these lathes feature robust cast iron beds, high-speed spindles, and advanced measurement systems (e.g., laser or probe detection). For instance, HAISHU’s CKL-35 vertical wheel repair lathe boasts a maximum processing diameter of 35 inches, making it versatile for cars, trucks, and SUVs. The best wheel repair lathe combines durability, automation, and user-friendly interfaces—often with LCD touchscreens—to cater to small repair shops and large-scale CNC lathe factories.

1.1 Key Specifications of a Best Wheel Repair Lathe

- Max Turning Diameter: Up to 710 mm (e.g., HAISHU CKL-26Q)

- Spindle Speed: 50-2000 RPM for precise cutting

- Measurement System: Non-contact laser (10-15 seconds detection) or probe

- CNC System: Proprietary software with automatic curve generation

- Material Compatibility: Aluminum alloys, steel rims

These specs ensure the best wheel repair lathe meets the demands of modern wheel refurbishment, delivering high-gloss finishes and structural integrity.

2. What Are Functions of the Best Wheel Repair Lathe?

The best wheel repair lathe serves multiple critical functions, making it an indispensable tool in automotive workshops. Inspired by the versatility of CNC dental file grinders—which shape, polish, and sharpen with pinpoint accuracy—these lathes excel in wheel-specific applications.

2.1 Wheel Surface Restoration

Using diamond-cutting tools, the best wheel repair lathe smooths scratches, scuffs, and curb rash, achieving a mirror-like finish. HAISHU Machinery’s lathes, for example, employ high-precision linear guides to ensure uniform surface refurbishment.

2.2 Rim and Center Hole Machining

The lathe re-machines rims and center holes to precise dimensions, correcting warpage or misalignment. This function, akin to grinding dental files to exact profiles, ensures wheels fit perfectly on vehicles.

2.3 Customization and Refinishing

From adding custom patterns to refinishing brushed or painted surfaces, the diamond cutting wheel lathe machine offers flexibility. Advanced CNC systems allow operators to program unique designs, enhancing aesthetic appeal.

2.4 Efficiency Through Automation

Equipped with automated detection (e.g., laser scanning in 10-15 seconds), the best wheel repair lathe reduces manual labor. HAISHU’s proprietary software optimizes machining paths, streamlining workflows in busy shops.

These functions position the vertical wheel repair lathe as a powerhouse for both repair and enhancement, catering to diverse customer needs.

3. What Are the Advantages of the Best Wheel Repair Lathe?

Investing in the best wheel repair lathe offers significant benefits, particularly when sourced from reputable CNC lathe manufacturers like HAISHU Machinery. Here’s why it stands out.

3.1 Precision and Consistency

With accuracy down to 0.01 mm—comparable to CNC dental file grinders—the best wheel repair lathe ensures every wheel meets exact specifications. This precision reduces errors and enhances customer satisfaction.

3.2 Time and Labor Savings

Automation cuts repair times dramatically. For instance, HAISHU’s CK6160W lathe completes surface scans and optimizations in under a minute, compared to 10-20 minutes manually. This efficiency boosts shop throughput.

3.3 Cost-Effectiveness

Refurbishing wheels with the best wheel repair lathe is far cheaper than replacements, saving customers money and increasing your service revenue. Durable construction from a trusted CNC lathe factory ensures long-term ROI.

3.4 Versatility

Handling wheel sizes from 16 to 35 inches, the best wheel repair lathe adapts to various vehicles. HAISHU Machinery’s vertical and horizontal models cater to both compact shops and large-scale operations.

3.5 Competitive Edge

Offering high-quality repairs with advanced technology sets your business apart. HAISHU’s global reputation—backed by 30+ patents and exports to 60+ countries—enhances your credibility when you choose their equipment.

These advantages make the best wheel repair lathe a strategic asset for any automotive repair business.

4. What Are Disadvantages of the Best Wheel Repair Lathe?

While the best wheel repair lathe offers transformative benefits, it’s not without challenges. Understanding these drawbacks ensures informed decision-making.

4.1 High Initial Cost

Prices for the best wheel repair lathe range from $10,000 to $20,000+, depending on features. For small shops, this upfront investment—though offset by long-term savings—can strain budgets.

4.2 Learning Curve

Despite user-friendly interfaces, operating a CNC lathe requires training. Unlike CNC dental file grinders, which demand specialized skills, wheel lathes need about 30-60 minutes of instruction—still a hurdle for novices.

4.3 Maintenance Requirements

Regular upkeep, such as lubricating linear guides or updating software, is essential. A CNC lathe factory like HAISHU provides support, but neglecting maintenance can lead to downtime.

4.4 Space Considerations

Vertical models like HAISHU’s CKL-35 save space, but horizontal lathes may require more room. Shops with limited floor area must plan accordingly.

These disadvantages highlight the need to weigh costs and capabilities when selecting the best wheel repair lathe.

5. Main Considerations When Choosing the Right Best Wheel Repair Lathe

Selecting the best wheel repair lathe involves evaluating several factors to match your shop’s needs. Here’s a detailed breakdown, informed by industry standards and HAISHU Machinery’s offerings.

5.1 Wheel Size Compatibility

Ensure the lathe handles your target wheel range. HAISHU’s CKL-35, with a 35-inch capacity, suits diverse vehicles, while the CK6160Q (24 inches) is ideal for smaller rims.

5.2 Precision and Measurement Systems

Look for laser or probe detection for speed and accuracy. HAISHU’s lathes offer both, with laser scans taking just 10-15 seconds—mirroring the precision of CNC dental file grinders.

5.3 Build Quality and Durability

A cast iron or steel bed ensures stability during high-speed operations. HAISHU Machinery’s 12,000-square-meter CNC lathe factory produces robust machines designed for heavy-duty use.

5.4 Automation and Software

Advanced CNC systems reduce operator effort. HAISHU’s proprietary software includes teaching functions and free lifetime upgrades—a competitive advantage over other CNC lathe manufacturers.

5.5 Motor Power and Speed

A spindle speed of 50-2000 RPM and a strong motor (e.g., 5.5 kW) ensure smooth cutting. HAISHU’s servo-driven spindles deliver consistent performance.

5.6 Budget and Support

Balance cost with quality. Entry-level lathes start at $10,000, while premium models exceed $20,000. HAISHU offers remote diagnostics and global agent support, minimizing downtime.

5.7 Shop Space and Workflow

Vertical lathes save space; horizontal ones suit larger setups. Assess your layout and repair volume to choose the right fit.

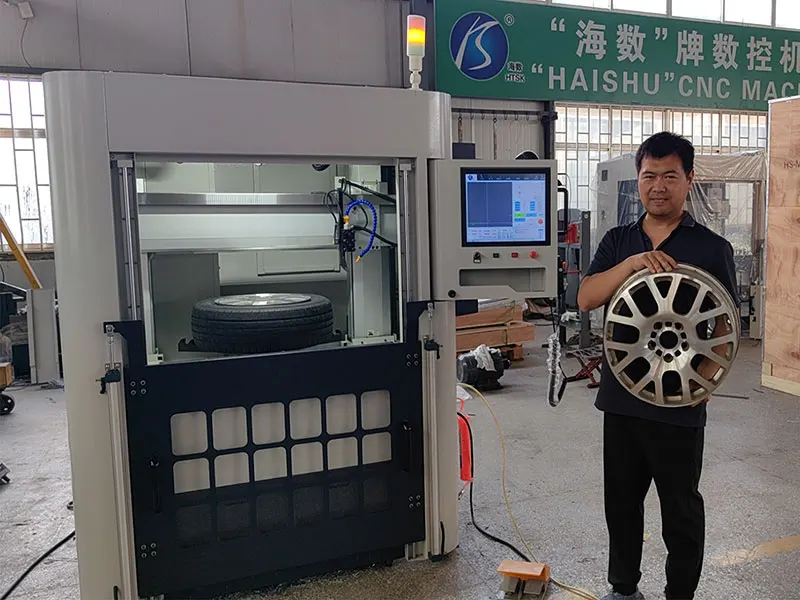

6. Why Choose HAISHU Machinery?

HAISHU stands out among CNC lathe manufacturers for its innovation (30+ patents), quality (ISO9001 certified), and customer focus. Their 25+ years of experience, collaboration with universities like Shandong University, and exports to 60+ countries underscore their reliability. Unlike competitors, HAISHU provides free software upgrades, remote training, and a network of agents, ensuring your best wheel repair lathe remains cutting-edge.

7. Final Thoughts

Choosing the best wheel repair lathe is a pivotal step toward elevating your automotive repair business. This specialized CNC equipment offers unmatched precision, efficiency, and versatility, transforming damaged wheels into pristine assets. While the initial cost and learning curve present challenges, the long-term benefits—cost savings, customer satisfaction, and competitive differentiation—far outweigh them.

Among CNC lathe manufacturers, HAISHU Machinery emerges as a leader, blending advanced technology with practical support. Their wheel repair equipment models, like the CKL-35 and CK6160W, cater to diverse needs with robust construction, intuitive software, and global service. Whether you’re refurbishing rims for a high-end client or scaling up shop capacity, HAISHU delivers the tools to succeed.

Investing in the mobile wheel repair machine isn’t just about equipment—it’s about empowering your business with precision and reliability. Explore HAISHU Machinery’s offerings, assess your needs against our considerations, and take the leap toward a more efficient, profitable future in wheel repair.