1. How to Choose the Top Aluminum Wheel CNC Lathe?

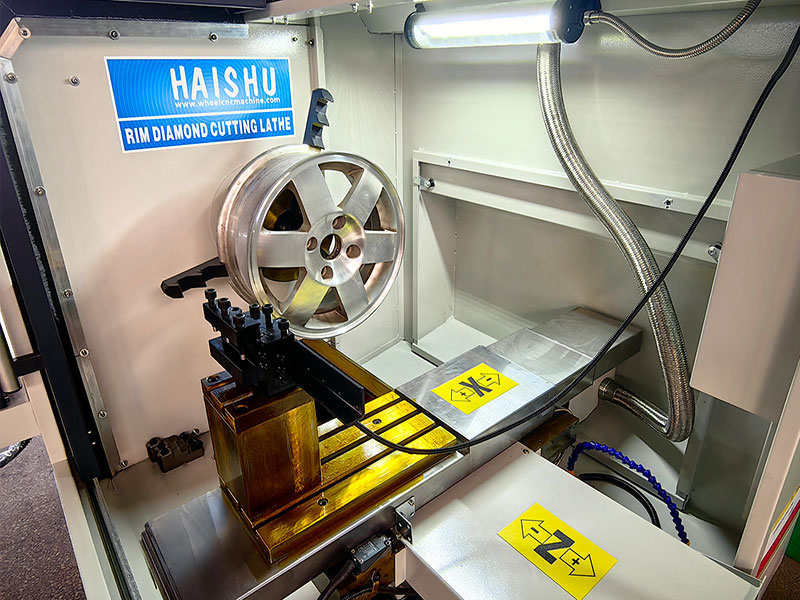

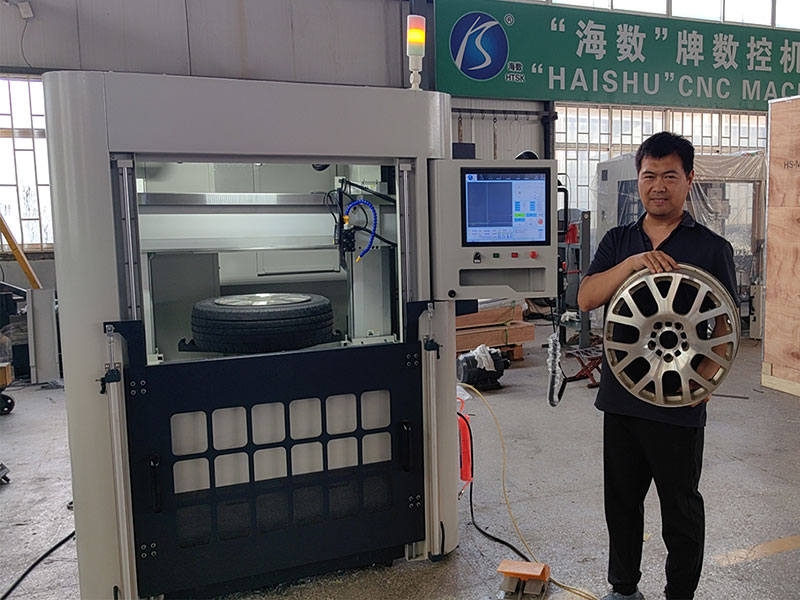

An aluminum wheel CNC lathe is currently the most advanced CNC lathe for automotive wheel repair. This wheel repair lathe is specifically designed for the repair and refurbishment of automotive aluminum alloy wheels. With so many types of wheel repair machines on the market, how should customers choose? Below, we introduce Haishu brand wheel repair lathes to provide customers with a comprehensive reference for their selection.

2. Which Wheel Size and Shape Suit the Top Aluminum Wheel CNC Lathe?

2.1 Analyzing Wheel Size for the Top Aluminum Wheel CNC Lathe

How should we choose based on different wheel sizes and shapes? First, analyze the size of the automotive wheel. If the lathe wheel size is within 21 inches, you can choose a horizontal wheel repair lathe. This is because a 21-inch automotive wheel is relatively small and suitable for repair using a horizontal structure. However, if the wheel size exceeds 22 inches, Haishu recommends choosing a vertical wheel repair lathe. Large wheels, when clamped vertically, can wobble due to significant centrifugal force. During processing, this centrifugal force can cause vibrations on the surface being machined, affecting the processing quality. Vertical wheel repair machines place the wheel flat on the fixture, solving the centrifugal force issue through gravity.

2.2 Choosing the Appropriate Wheel Repair Machine

It’s crucial to select the right wheel repair machine based on the wheel size and shape. Horizontal wheel repair lathes are ideal for smaller wheels, while vertical wheel repair lathes are better suited for larger wheels. This ensures the machine’s stability and precision during the wheel refurbishment process.

3. What Configuration is Required for the Top Aluminum Wheel CNC Lathe?

3.1 Essential Features of a Wheel CNC Machine

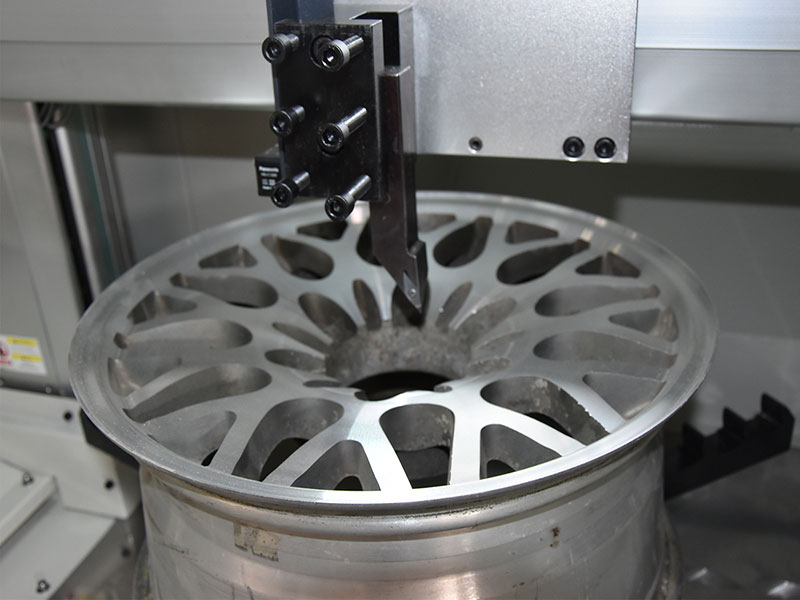

The configuration of the aluminum wheel CNC lathe also has many requirements. For example, the wheel repair system. Haishu’s automotive wheel repair system uses a 17-inch touchscreen panel with many modern and easy-to-operate functions. One such feature is one-click laser detection, which completes detection in just 15 seconds. In contrast, traditional contact probes take about 5 minutes to complete surface detection. Laser detection does not require contact with the wheel surface, avoiding collisions and damage, and has low maintenance and update costs.

3.2 Advanced Functions of the Wheel Repair System

The advanced functions of Haishu’s wheel repair system make it stand out. Features such as one-click laser detection not only save time but also enhance the accuracy and safety of the wheel repair process. These modern innovations in wheel CNC machines ensure efficient and precise alloy wheel repair.

4. How is Curve Optimization Achieved in the Top Aluminum Wheel CNC Lathe?

4.1 Traditional vs. Modern Curve Optimization

Regarding curve optimization, old methods required manual memory of coordinate points and step-by-step CNC programming. This not only demanded high technical skills from operators but also took a long time, resulting in low efficiency. To address this, Haishu uses automatic and manual curve optimization, replacing complex manual programming. Users can optimize or manually adjust the wheel curve with one click and directly output the CNC program without complex manual programming. This process takes only one minute, significantly reducing the need for high technical skills and lowering labor costs for customers.

4.2 Benefits of Automated Curve Optimization

The automated curve optimization in Haishu’s wheel CNC machine allows for quick and accurate adjustments, enhancing the overall efficiency of the wheel refurbishment machine. This feature is particularly beneficial for workshops looking to improve their production speed and reduce dependency on highly skilled labor.

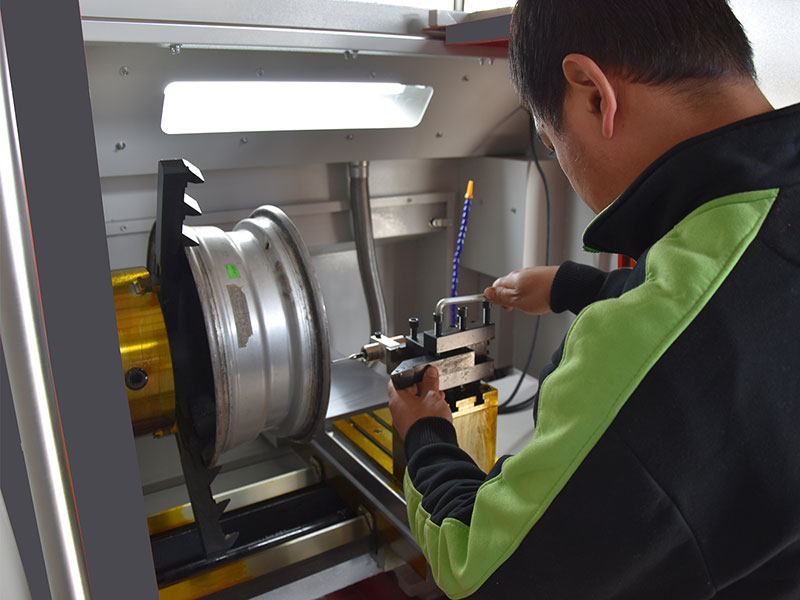

5. How to Set Tools in the Top Aluminum Wheel CNC Lathe?

5.1 Simplified Tool Setting Process

Haishu has also optimized tool settings for customers, eliminating the need for complex tool alignment operations. One-click tool setting allows users to set the tool’s machining starting point with a single button press. If the tool position is set incorrectly due to operator error, Haishu’s customized coordinate offset module can correct it, simplifying the process.

5.2 Advantages of One-Click Tool Setting

The one-click tool setting feature in Haishu’s wheel repair lathe simplifies the setup process, making it user-friendly even for operators with minimal experience. This ensures that the alloy wheel repair process is not only precise but also efficient, reducing downtime and increasing productivity.

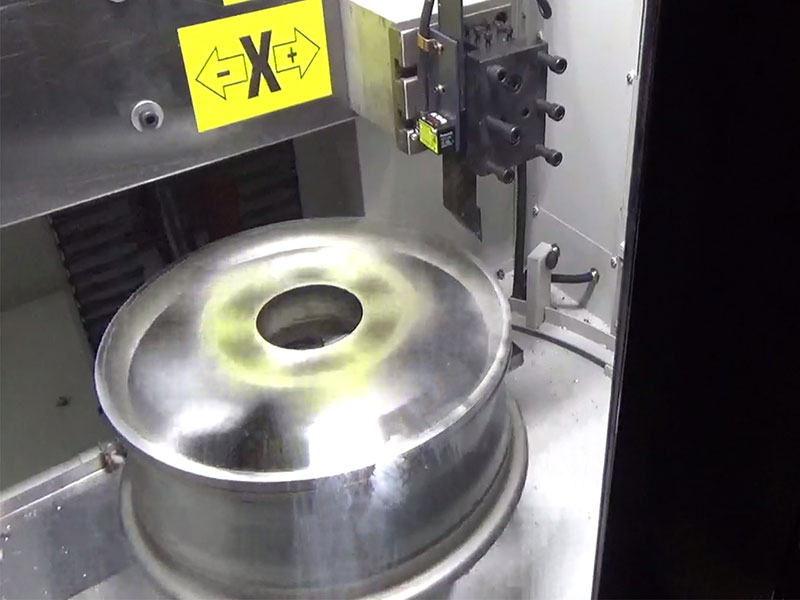

6. What Are the Program and Tool Configuration Steps in the Top Aluminum Wheel CNC Lathe?

6.1 Easy-to-Use Program Configuration

Once the program and tools are set, users can directly call the CNC program without navigating complex interfaces. Combined with Haishu’s one-click machining function, precise wheel surface repair can be performed effortlessly. Haishu has optimized and upgraded every step of the operation to ensure that even individuals with no prior experience can use Haishu’s wheel repair lathe for alloy wheel repair.

6.2 Streamlined Tool Configuration

The streamlined tool configuration in Haishu’s wheel CNC machine means that operators can quickly set up and begin the wheel refurbishment process. This feature is essential for workshops that need to maintain high throughput and consistent quality in their wheel repair services.

7. What ODM Services Are Offered by the Top Aluminum Wheel CNC Lathe?

7.1 Customization Options for Wheel Repair Machines

Haishu also offers ODM services, allowing customers to have their own brand. We provide various customization options to meet customer needs, such as voltage requirements. Custom voltage options include 110V, 220V, 380V, and 415V. Customers are encouraged to specify their requirements in detail, and Haishu will provide customized services to meet those needs.

7.2 Benefits of ODM Services

The ODM services provided by Haishu ensure that customers can tailor their wheel repair machines to meet specific operational requirements. This customization enhances the versatility and utility of the wheel CNC machine, making it a valuable asset for any wheel repair workshop.

8. Why Choose Haishu’s Top Aluminum Wheel CNC Lathe?

8.1 Comprehensive Benefits

Haishu’s aluminum wheel CNC lathe offers comprehensive benefits, including advanced features, user-friendly interfaces, and customizable options. These advantages make Haishu’s wheel repair lathe the top choice for workshops looking to enhance their wheel refurbishment capabilities.

8.2 Enhancing Workshop Efficiency

By choosing Haishu’s wheel repair machine, workshops can significantly improve their efficiency and output quality. The advanced features and customization options ensure that the wheel refurbishment process is both precise and streamlined, reducing operational costs and increasing customer satisfaction.

9. What Makes Haishu’s Top Aluminum Wheel CNC Lathe Stand Out?

9.1 Innovative Technical Features

Haishu’s wheel CNC machine incorporates innovative technical features that distinguish it from other wheel repair machines on the market. These features include automated curve optimization, one-click tool setting, and advanced laser detection, all designed to enhance the efficiency and precision of alloy wheel repair.

9.2 User-Friendly Design

The user-friendly design of Haishu’s wheel repair lathe ensures that even operators with minimal technical expertise can perform high-quality wheel repairs. The intuitive touchscreen interface and straightforward program configuration make the machine accessible and easy to use.

10. How Does Haishu’s Top Aluminum Wheel CNC Lathe Reduce Costs?

10.1 Lower Maintenance and Update Costs

Haishu’s wheel CNC machines are designed with low maintenance and update costs in mind. The use of non-contact laser detection reduces the risk of damage to the wheel surface, minimizing the need for repairs and replacements. Additionally, the automated features reduce the dependency on highly skilled labor, further lowering operational costs.

10.2 Increased Productivity

The advanced features of Haishu’s wheel repair lathe, such as one-click machining and automated curve optimization, significantly increase productivity. These features allow workshops to complete more wheel repairs in less time, improving overall efficiency and profitability.

10.3 Conclusion

In conclusion, selecting the top aluminum wheel CNC lathe involves considering various factors such as wheel size, shape, configuration requirements, and advanced features. Haishu’s wheel repair lathes provide a comprehensive solution for alloy wheel repair, ensuring precision, efficiency, and ease of use. With customization options and advanced automation features, Haishu’s CNC wheels are the ideal choice for any wheel repair and refurbishment workshop. By investing in Haishu’s wheel repair lathes, workshops can enhance their service quality, reduce labor costs, and improve overall productivity.