1. How do you measure the rim straightening machine price?

When selecting a rim straightening machine, understanding the various price points and features is crucial for making an informed investment. This extensive guide will delve into different types of rim straightening machines, such as wheel repair lathes, wheel CNC machines, and general wheel repair machines, providing in-depth insights to help you navigate the complexities of rim straightening machine prices. Each section will address specific questions related to the cost and features of these machines, ensuring a well-rounded understanding of what you’re investing in.

2. What Determines the Price of Basic Rim Straightening Machines?

2.1 Factors Influencing Cost

Rim straightening machines without cutting capabilities primarily focus on correcting wheel deformities using mechanical means such as claws and hydraulic jacks. These are generally less expensive than more advanced models but vary in price based on the control system for the hydraulic jacks—manual or automatic.

2.2 Manual vs. Automatic Hydraulic Systems

The manually controlled machines are more cost-effective and suitable for operations with limited budgets or lesser repair volume. They require physical labor to operate, which can be strenuous and less efficient for significant deformations. On the other hand, automatic machines, though more expensive, offer ease of use and greater efficiency, making them a worthy investment for busy workshops.

3. How Do Cutting Functions Affect Rim Straightening Machine Prices?

3.1 Price Comparison of Cutting vs. Non-Cutting Machines

Machines equipped with cutting functions, such as wheel repair lathes, are priced higher due to their dual capabilities. These machines not only straighten but also trim and refine the wheel, handling more complex repair tasks.

3.2 Enhanced Capabilities with Cutting Functions

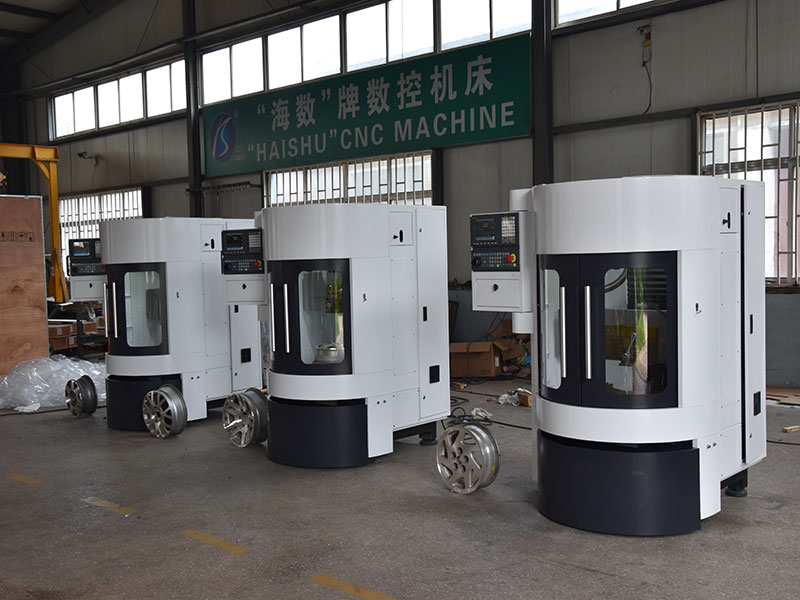

Wheel repair machines with cutting functions from brands like Taian Haishu offer advanced features such as a 360-degree rotating tool holder, allowing for precise machining at various angles. This versatility justifies the higher price point as it enhances the scope of repairs, ensuring a broader service offering for repair shops.

4. What Role Does CNC Technology Play in Rim Straightening Machine Pricing?

4.1 Impact of CNC on Pricing

Wheel CNC machines represent the pinnacle of wheel repair technology, incorporating computer numerical control to achieve high precision and consistency in repairs. The integration of CNC technology significantly increases the machine’s price due to its advanced engineering and resultant operational efficiencies.

4.2 Benefits of CNC Machines

The precise control offered by CNC machines reduces material waste and error rates, providing long-term savings and higher customer satisfaction. These machines are ideal for high-volume environments where precision and repeatability are crucial.

5. How Do Additional Features Influence Rim Straightening Machine Prices?

5.1 Overview of Additional Features

Additional features such as variable speed control, larger hydraulic stations, and a variety of accessories can also inflate the price of rim straightening machines. These features enhance the machine’s functionality and adaptability to different repair scenarios.

5.2 Assessing the Value of Add-ons

Investing in machines with these additional features can be cost-efficient in the long run, despite the higher initial price. Features like variable speed control and powerful hydraulic stations ensure that the machine performs optimally under various conditions, catering to a wide range of repair needs.

6. Does Brand Reputation Affect Rim Straightening Machine Prices?

6.1 Influence of Brand on Cost

Brands like Taian Haishu, known for their reliability and innovation in wheel repair machines, often command higher prices. These prices reflect the brand’s commitment to quality, durability, and customer support.

6.2 Benefits of Opting for Reputable Brands

Choosing a well-known brand can be more economical over time, considering the longevity and efficiency of the machine. Reliable customer service and the availability of parts and service can significantly reduce operational hitches and maintenance costs.

7. How Customizable Are Rim Straightening Machines and Their Prices?

7.1 Customization Options Available

Custom rim straightening solutions, which may involve specific functionalities or adaptations for unique wheel sizes, can vary greatly in price depending on the complexity and specifications required.

7.2 Cost Implications of Custom Solutions

While custom solutions are typically more expensive, they provide tailored functionality that can address specific operational needs, giving businesses a competitive edge and higher customer satisfaction.

8. What Should Be Considered When Evaluating Rim Straightening Machine Prices?

8.1 Comprehensive Price Evaluation

When assessing the price of a rim straightening machine, consider not only the initial purchase cost but also the operational and maintenance expenses over the machine’s lifespan.

8.2 Long-Term Considerations

Evaluate the potential return on investment through increased efficiency, customer satisfaction, and the ability to handle a wider range of repairs. Investing in a machine with the right features can lead to significant business growth and profitability.

This guide aims to provide a thorough understanding of the factors that contribute to the cost of rim straightening machines, from basic models to highly advanced systems. By considering each aspect under the mentioned headings, potential buyers can make well-informed decisions based on their specific wheel repair needs.