Alloy Wheel Rim Repair CNC Lathe is a specialized CNC lathe designed specifically for repairing alloy wheel rims. Alloy wheel rims are essential components of vehicles that are often exposed to challenging road conditions and environments, making them susceptible to scratches, dents, deformations, and other damages. These issues not only impact the vehicle’s aesthetic appeal but can also lead to uneven tire wear and unstable driving.

The significance and role of the Alloy Wheel Rim Repair CNC Lathe lie in its ability to efficiently and accurately repair various damages on alloy wheel rims, restoring them to their original state. By utilizing this equipment, users can effectively address surface scratches, dents, deformations, and other issues, resulting in wheel rims with a smooth and polished appearance. The repaired wheel rims not only enhance the vehicle’s visual quality but also improve driving comfort and safety.

Our vertical wheel repair lathe offers advanced capabilities to efficiently restore and enhance your alloy wheel rims. With our state-of-the-art wheel repair machine, we provide precise and effective repairs that meet the highest standards. Trust our expertise in alloy wheel repair to deliver exceptional results tailored to your needs.

Choose our wheel CNC machine for efficient restoration solutions that enhance your vehicle’s appearance, performance, and safety. Contact us now to learn more about our services and how our wheel repair machine can benefit you.

The wheel repair machine incorporates precise CNC technology and specialized repair tools to automatically execute various repair operations, ensuring consistent and accurate repair quality. It can repair alloy wheel rims of different sizes and shapes, making it suitable for various vehicle models and wheel designs.

Traditional methods of repairing alloy wheel rims typically involve extensive manual labor and time-consuming processes. In contrast, the Alloy Wheel Rim Repair CNC Lathe significantly enhances repair efficiency and quality, saving time and labor costs. It serves as a crucial tool in the automotive repair industry and wheel rim repair service providers, making it an ideal choice for car owners seeking flawless wheel rim appearance.

Experience the efficiency and precision of our vertical wheel repair lathe, equipped with advanced CNC technology and dedicated repair tools. Our state-of-the-art machine ensures consistent and accurate repairs, meeting the highest industry standards. Contact us now to discover how our services can benefit your alloy wheel repair needs.

The purpose of operating the Alloy Wheel Rim Repair CNC Lathe is to guide users in the correct usage of the equipment and achieve effective repair of alloy wheel rims. Through clear operating instructions, users will be able to understand how to install the wheel rim, set repair parameters, select appropriate tools and cutters, start the equipment, monitor the repair process, and ultimately complete the repair and perform subsequent treatments.

At our company, we provide comprehensive guidance on operating the Alloy Wheel Rim Repair CNC Lathe to ensure successful alloy wheel rim repairs. Our detailed instructions cover the installation process, parameter settings, tool and cutter selection, equipment startup, real-time monitoring of the repair process, and the final completion of the repair with subsequent treatments.

Choose our services for expert guidance on operating the Alloy Wheel Rim Repair CNC Lathe and achieving efficient and effective alloy wheel rim repairs. Contact us now to learn more about our services and how our expertise can benefit your alloy wheel repair needs.

Alloy Wheel Rim Repair CNC Lathe Product Overview

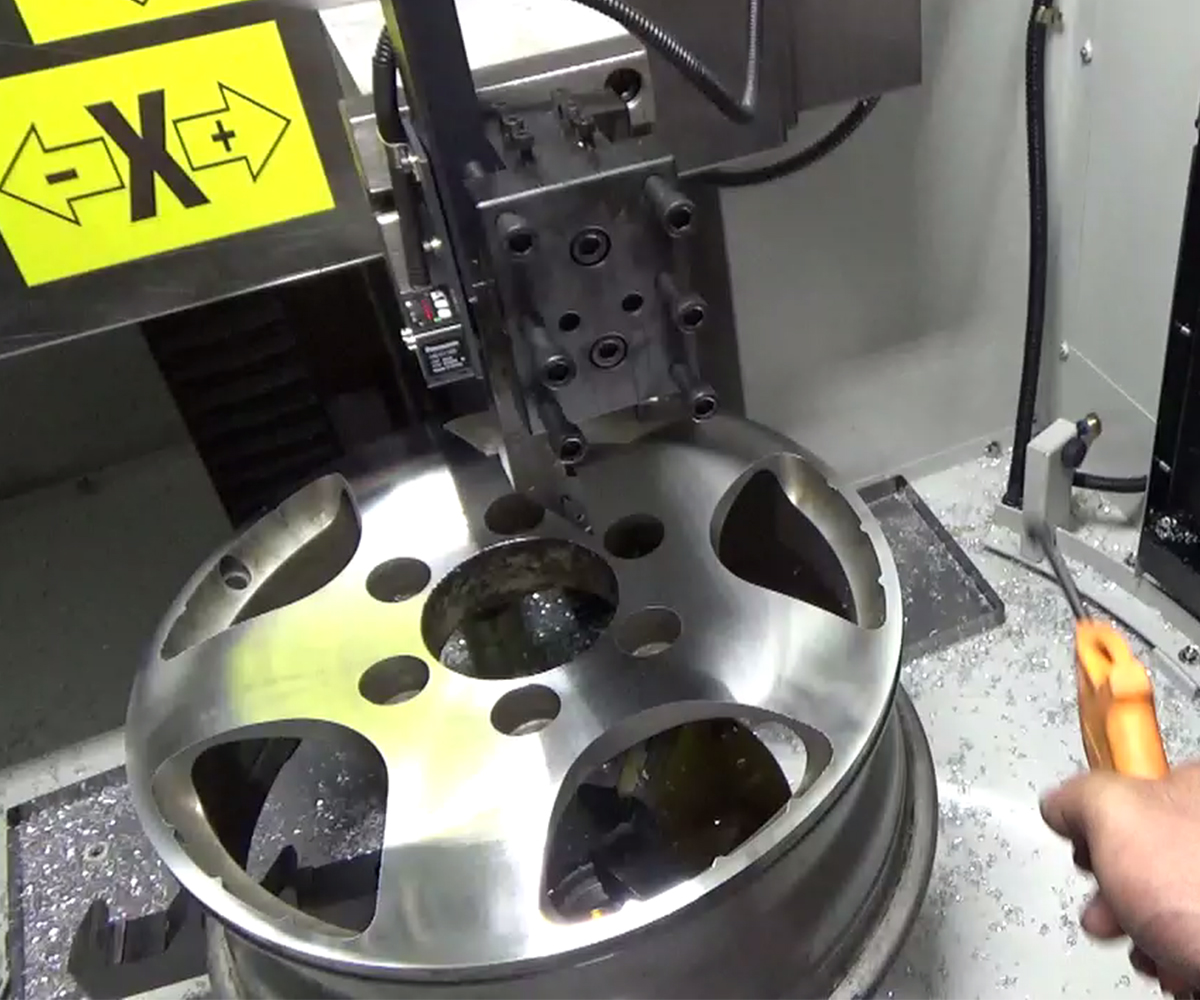

The working principle of the wheel CNC machine involves laser detection of the surface shape of the wheel rim, forming the rim curve, optimizing the curve path through system optimization, and generating CNC machining programs. Then, suitable tools are selected for automatic tool alignment and machining, ultimately completing the repair process.

Equipment Preparation: Check the integrity and safety of the equipment, ensure proper connection to power sources and other necessary interfaces, and perform equipment initialization and calibration.

Wheel Rim Installation: Properly mount the alloy wheel rim to be repaired on the equipment for repair operations.

Parameter Settings: Set repair parameters, such as repair depth and repair area, through the user interface based on the condition of the wheel rim damage.

Tool Selection and Installation: Choose suitable repair tools and cutters based on the repair requirements and install them on the spindle.

Equipment Startup: Initiate the equipment through the CNC system, and the equipment will automatically execute the repair operation based on the preset repair parameters and operating instructions.

Monitoring and Adjustment: During the repair process, monitor the repair effect and equipment operation status, and make timely adjustments to repair parameters and operating instructions to ensure repair quality and effectiveness.

Completion of Repair: When the repair operation is completed, the equipment will automatically stop, and subsequent treatments such as cleaning the repair area and inspecting the repair effect can be performed.

The HAISHU Alloy Wheel Rim Repair CNC Lathe features include:

CNC System Automation: The automated and user-friendly CNC system eliminates the need for complex manual operations, making it easier to operate and reducing the learning curve.

High Precision: Our Alloy Wheel Rim Repair CNC Lathe combines linear guides and ball screws to achieve precise machining of wheel rim surfaces.

Versatility: The machine offers various detection methods and techniques to cater to different types of wheel rims, providing diverse and practical functionality.

High Universality: The repair lathe accommodates wheel rim sizes ranging from 16 inches to 35 inches, making it suitable for both small cars and large pickup trucks, ensuring efficient service and perfect repairs.

User-Friendly Interface: The one-touch operation and intuitive interface allow customers to easily locate and understand the operation buttons. Its simplicity and efficiency are its key competitive advantages.

Safety and Reliability: Safety features such as alarm systems and travel alarms are incorporated to ensure a safe environment and enjoyable experience during wheel rim repairs.

Equipment Preparation for the Alloy Wheel Rim Repair CNC Lathe

• Check the integrity and safety of the equipment

First, inspect the overall appearance of the Alloy Wheel Rim Repair CNC Lathe for any damages and ensure the equipment is complete. Also, check the stability of the chuck installation.

• Ensure proper connection to power sources and other necessary interfaces

Confirm that the purchased Alloy Wheel Rim Repair CNC Lathe operates at the correct voltage. The mainstream voltage options include three-phase 220V, 380V, 415V, and single-phase 220V. If there are other voltage requirements, please specify them during the purchase. Additionally, verify the connection of the mouse, and ensure the installation of shims.

• Perform equipment initialization and calibration

When the equipment is powered on, pay attention to the homing setting. This is crucial for calibrating the machine’s position and is a fundamental operation that should be carefully remembered. Also, remove any anti-rust grease, add lubricating oil to the electric oil pump, and insert an air hose into the air inlet.

Steps for Operating the Alloy Wheel Rim Repair CNC Lathe

Once the aforementioned steps are confirmed, I will proceed with explaining the specific operating steps of the Alloy Wheel Rim Repair CNC Lathe.

First, properly mount the wheel rim to be repaired on the equipment. We offer two installation methods: center positioning and chuck clamping. Currently, the majority of users prefer chuck clamping. For the convenience of our customers, we provide an extended version of the chuck wrench, making the process simple and efficient.

After the wheel rim installation, we have a laser probe switch setting in the software. This is to protect the workers’ eyes, so remember to turn it on in advance.

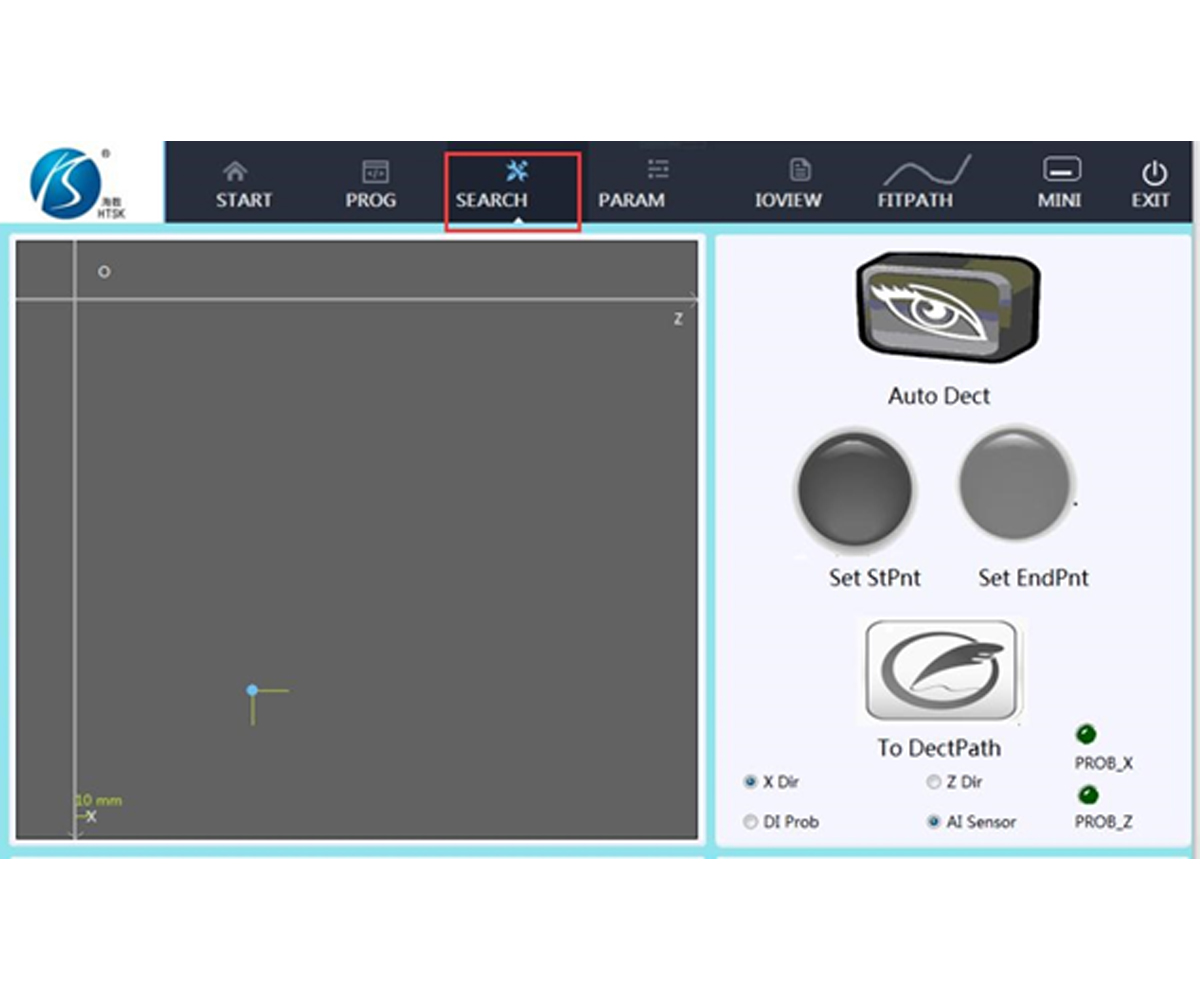

Next, we proceed with wheel rim detection. In the wheel rim detection process, we set the starting and ending points for the detection, and there are specific requirements for the signal strength of the laser probe. This is crucial as it directly impacts the accuracy of the detected wheel rim surface.

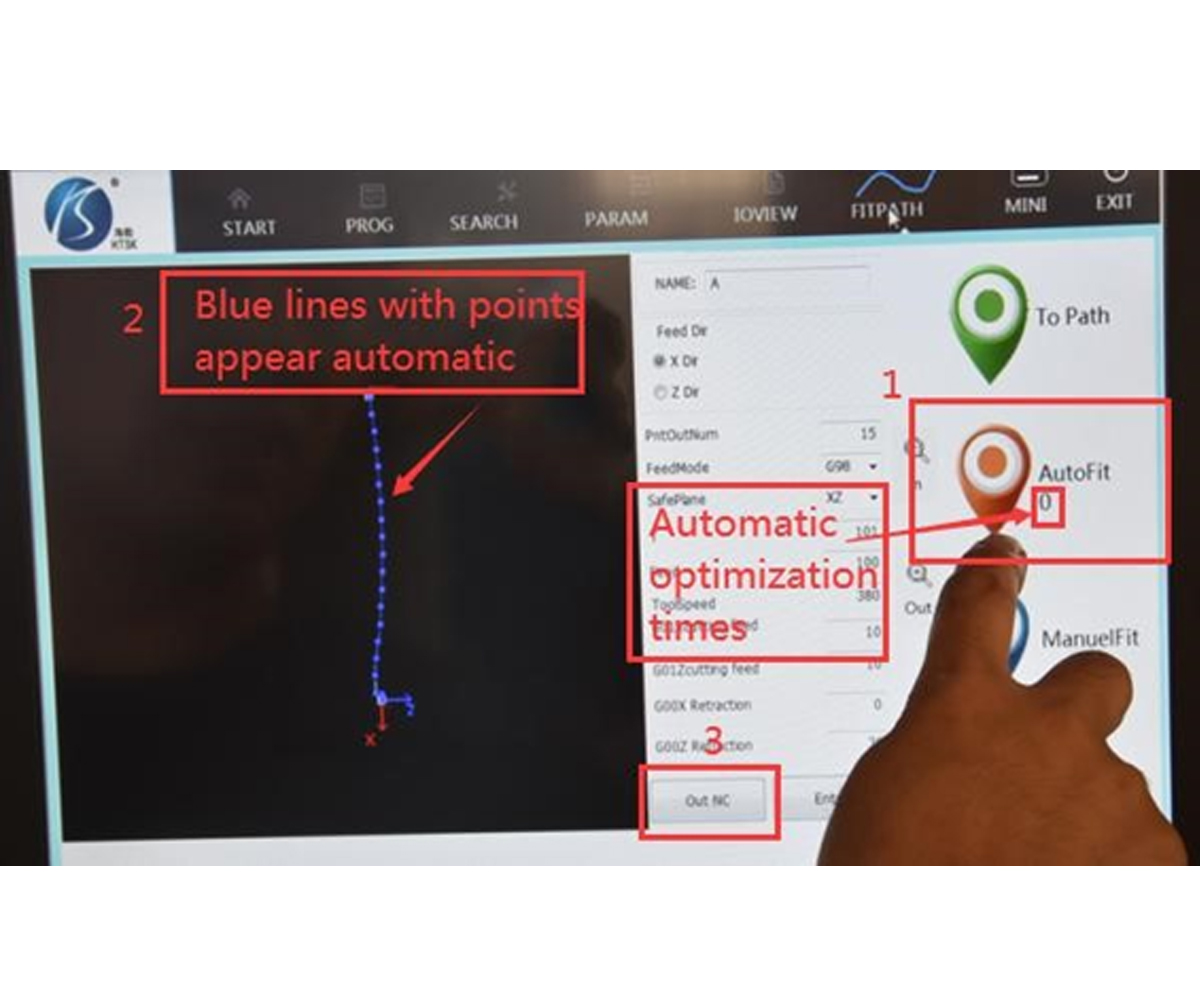

Once the wheel rim detection is completed, we move on to the curve optimization setting. Our Alloy Wheel Rim Repair CNC Lathe provides customers with the option of automatic or manual optimization, catering to their specific needs. Customers can choose the optimization method according to their requirements.

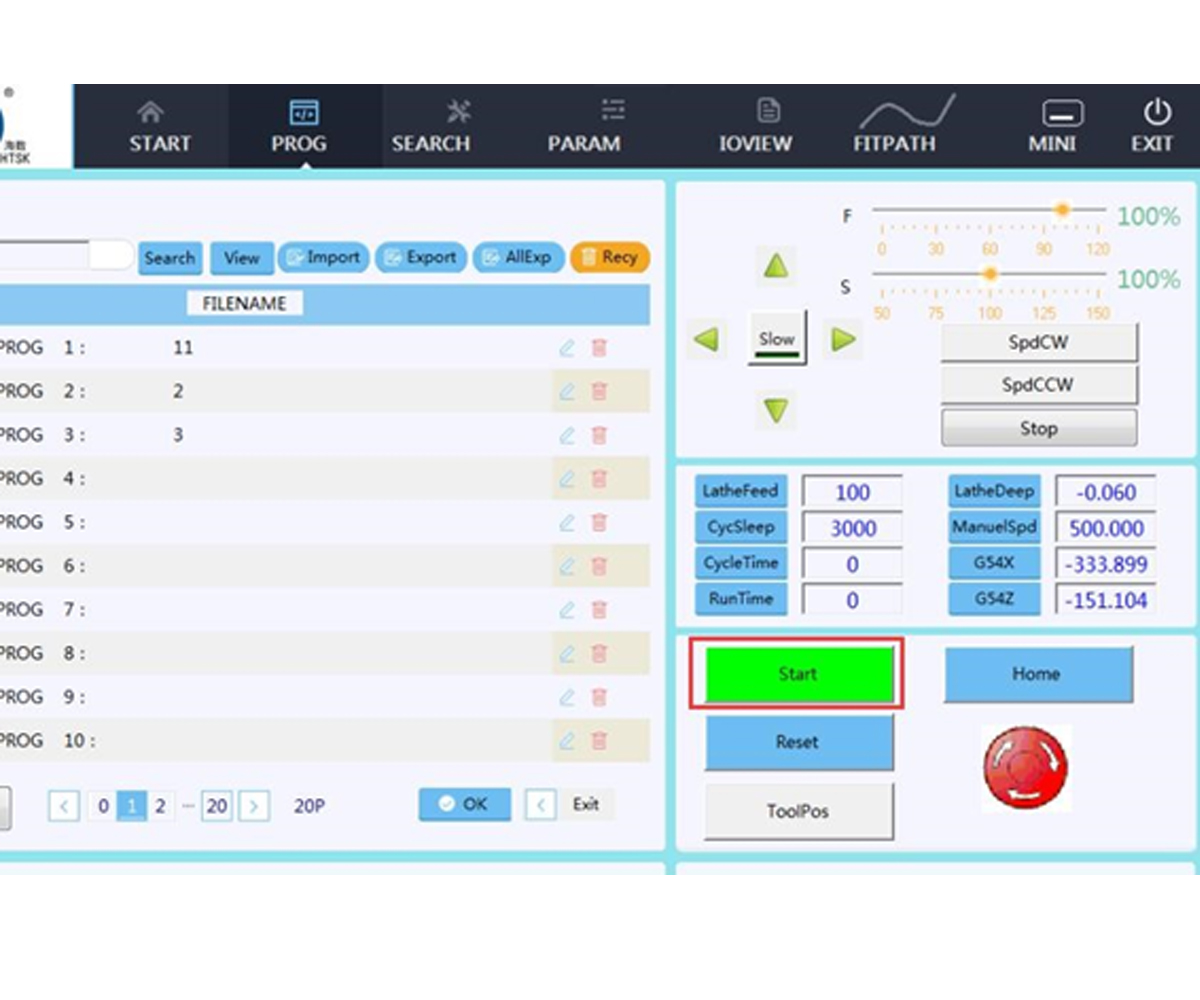

After the optimization is completed, we proceed to the program output step. We provide two machining programs for the customers: one is the standard program based on the original wheel rim curve, and the other is the optimized program. When selecting the program, choose the machining program. The program based on the original wheel rim surface is provided for comparison and modification purposes. If the customer doesn’t require it, it can be skipped.

Once everything is prepared, we carefully select the tool direction based on the shape of the wheel rim. This is crucial because only the appropriate tool direction can effectively machine the wheel rim surface.

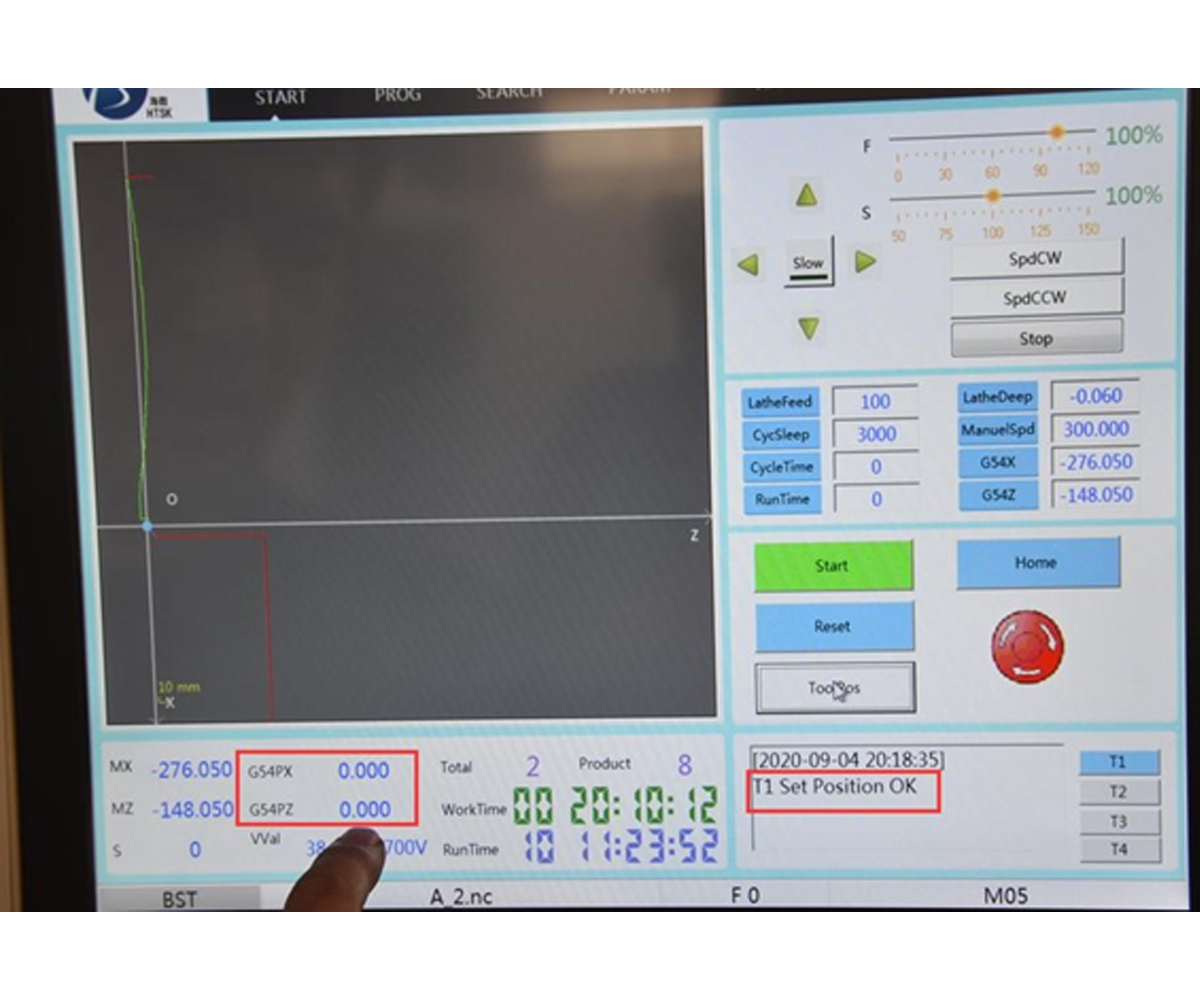

Once the tool selection and installation are completed, the next step is to proceed with tool position setting, which is a simple process achieved through the one-key tool alignment function.

The final step is to close the protective door and select the machining program. With just a single button start, customers can initiate the automatic machining process. During this process, they have the flexibility to modify coordinates according to their specific requirements, and the machining results are exceptionally precise.

After the completion of the machining process, it is important to use the provided air source to clean the wheel rim surface to prevent any scratches.

Troubleshooting and Common Issues with alloy wheel repair lathe

- After powering on the machine, there may be an emergency stop alarm. This is because we pressed the emergency stop switch before shipping the equipment. To resolve this, manually rotate the button to the right and press the reset button.

- Some customers may encounter alarm notifications regarding exceeded travel limits during their initial operation. There is no need to worry as the travel positions can be adjusted in the system parameters.

- If you encounter any other unresolved alarm issues, simply contact us. Our technical support team will promptly provide video solutions and telephone guidance.

Safety Precautions for wheel repair lathe

- When installing the wheel rim, ensure that no one touches the system buttons in the vicinity.

- Please wear insulated shoes and work clothes.

- Ensure that the machine’s surroundings are not in a damp environment, as it can cause short circuits or electric shock risks. We have also added short circuit protection devices.

Maintenance and Care for Alloy Wheel Rim Repair CNC Lathe

- Regular lubrication and maintenance are crucial for the Alloy Wheel Rim Repair CNC Lathe. Protecting the lead screws is particularly important.

- The position of the travel switch should be regularly cleaned to prevent aluminum chips from obstructing the switch.

- Regular maintenance and care of the Alloy Wheel Rim Repair CNC Lathe are necessary to ensure safe operation and help increase the equipment’s lifespan.

After purchasing our Alloy Wheel Rim Repair CNC Lathe, we provide detailed operating instructions and prominent instructional signs to guide customers. They will learn to operate the CNC wheel rim lathe in a relaxed and enjoyable environment. This is crucial for a seamless learning experience.

If you would like to know which specific model of wheel rim repair lathe is suitable for you, please contact me via email or phone.