Mobile Alloy Wheel Refurbishment Equipment CK6160Q: A Game-Changer in Wheel Repair

The Pinnacle of Wheel Repair Lathe Technology

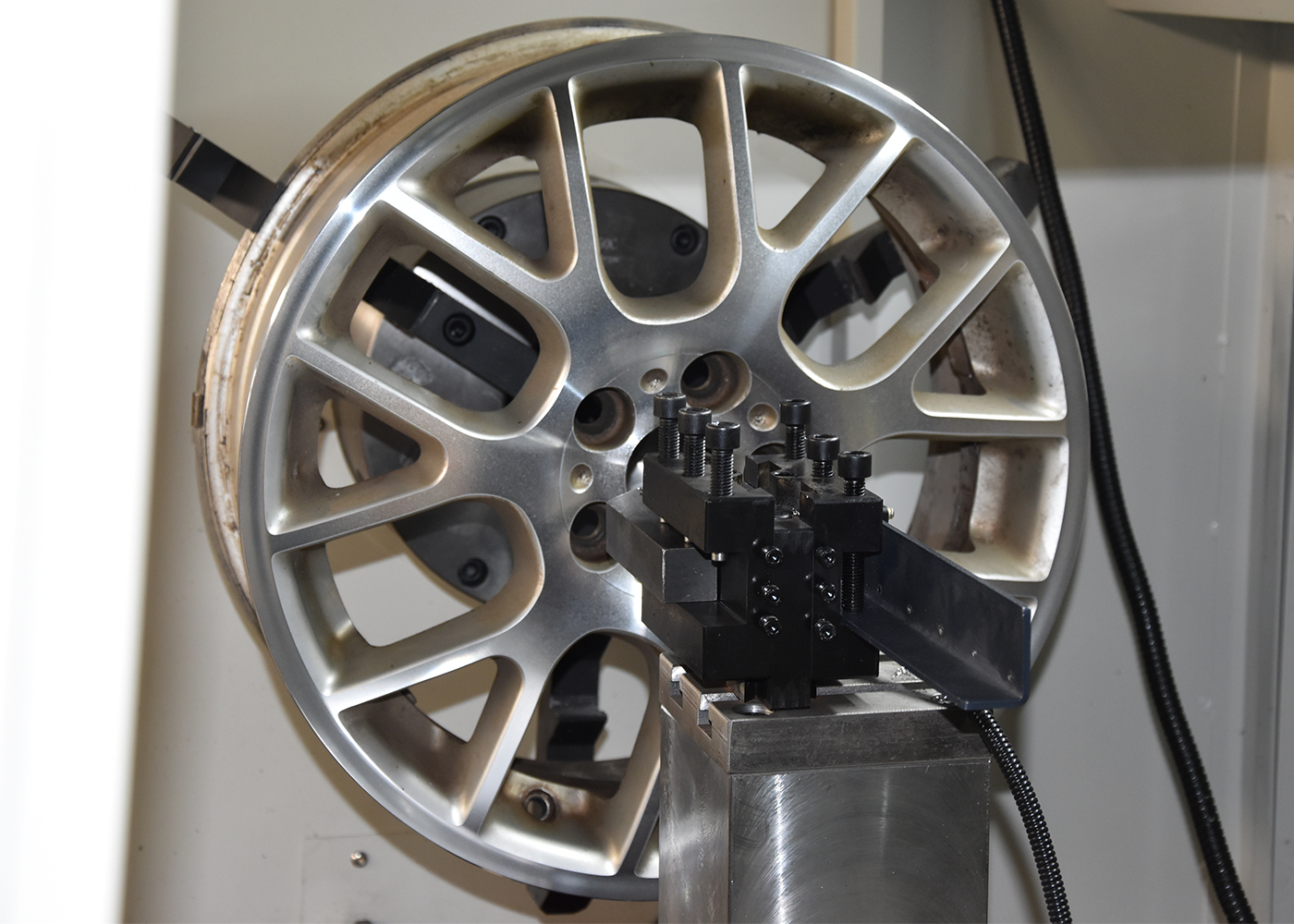

Haishu Machinery’s Mobile Alloy Wheel Refurbishment Equipment CK6160Q represents the cutting edge in wheel CNC machine technology, offering unparalleled services in alloy wheel repair and maintenance for car repair workshops. This equipment is the epitome of innovation, featuring a self-developed CNC system that is both highly efficient and user-friendly, with an intuitive touchscreen interface.

The wheel repair lathe CK6160Q is a marvel of engineering, boasting mechanical parts designed and manufactured in-house, such as the robust casting bed, spindle, and precise fixing chuck. Its feeding mechanism, coupled with a sophisticated numerical control system, automatic measuring capabilities, and high-quality servo motors, underpins its exceptional performance. When it comes to mobile alloy wheel refurbishment equipment, the CK6160Q is built to handle wheels up to 22 inches in size, catering to a broad range of wheel repair needs.

Tailored Solutions for Diverse Needs

Understanding that our Australian client required a wheel repair machine for smaller wheels, typically less than 20 inches in diameter, the CK6160Q was the perfect match. Its compact size, weighing approximately 1500kg, does not compromise on precision and can readily process wheels up to 22 inches. The addition of both probe and laser detection systems automates the process, enhancing accuracy and user satisfaction.

The operation videos of our alloy wheel CNC lathe demonstrate its capabilities, leaving the client impressed and indicating potential for future purchases.

Feature-Rich Mobile Alloy Wheel Refurbishment Equipment

- Simplicity in design with a low-cost investment and a high-performance ratio.

- The option of laser scanning or probe click measurement for versatility.

- Automatic storage of wheel data and easy retrieval of machining programs.

- Custom-developed software that automatically optimizes programs.

- Fast, precise, and fully automated wheel processing.

- Multi-language support on the touchscreen interface.

- X/Z axis measurement for comprehensive wheel surface and circumferential machining.

- An automatic lubrication system for smooth operation.

- Diamond cutting tool for a superior wheel surface finish.

- The inclusion of a teaching function for hands-on computer learning.

- Customization options to meet specific customer requirements.

Commitment to Excellence and Innovation

At Haishu Machinery, our dedication to R&D, manufacturing excellence, and technical training has positioned us as a leading provider of wheel CNC lathes. Our long-standing partnerships with esteemed American automotive maintenance companies testify to our global reach and expertise.

Our Mobile Alloy Wheel Refurbishment Equipment has embraced and refined global automotive aluminum alloy wheel repair technologies, filling significant gaps in the Chinese automobile wheel repair industry. We are unwavering in our mission to spearhead the professional auto wheel repair market in China and to set trends in wheel repair services. Haishu Machinery is not just a company; it is a beacon of green, energy-saving, and environmental stewardship in the auto repair industry, redefining the concept of ‘turning waste into treasure’.

The Future of Mobile Alloy Wheel Refurbishment

As the demand for mobile alloy wheel refurbishment equipment escalates, Haishu Machinery continues to innovate, ensuring that our CK6160Q remains the benchmark for wheel repair solutions. With our commitment to quality, sustainability, and customer satisfaction, we are paving the way for a brighter, more efficient future in the wheel repair industry.