New vertical wheel repair lathe is a type of mechanical equipment that is primarily used for repairing and machining vehicle wheel hubs. It can rotate the wheel hub and utilize cutting tools for operations such as trimming the surface of the hub, adjusting the hub’s diameter and depth, and repairing dents and scratches on the hub’s surface. Its vertical design allows the hub to be fixed on the worktable and machined in one plane, making the machining more precise and convenient. This equipment is typically used in the automotive repair, modification, and manufacturing industries.

Tai’an Haishu Machinery Co., Ltd. has developed and produced a wheel repair lathe specifically designed for customers in Europe and America. This equipment is designed to meet the demand for high-quality and high-precision wheel repair equipment in the European and American markets. Our customers have highly praised the performance of this equipment, stating that its reliability and stability have met their expectations. We will continue to devote ourselves to product innovation and technological research and development, providing our customers with high-quality services and products

The shortcomings of ordinary or old-fashioned wheel lathes are mainly due to their relatively low structural design and technical level, which cannot meet the high-quality, high-efficiency, and diversified demands of modern wheel machining. In practical applications, these problems can cause the following impacts:

Firstly, the low processing efficiency of old-fashioned wheel lathes leads to slow processing speed and high time and labor costs, making it difficult to meet the demands of modern enterprises for fast and efficient production.

Secondly, the low processing accuracy of old-fashioned wheel lathes makes it difficult to ensure the surface finish and precision of wheel hubs, resulting in defects and affecting overall quality, which cannot meet the high-quality requirements of modern automobile manufacturing.

Moreover, the high technical difficulty of operating old-fashioned wheel lathes requires professional technicians, making it difficult to recruit enough personnel and causing high labor costs, which is difficult for some small and medium-sized enterprises to bear.

In addition, the single function of old-fashioned wheel lathes cannot meet the diversified demands of the market and adapt to the varying machining requirements of different vehicle models and wheel hubs, which limits the competitiveness of enterprises in the market.

Finally, the expensive price and high maintenance costs of old-fashioned wheel lathes make it difficult for some individual repair shops to bear the cost burden, affecting the competitiveness and profit margins of Europe and America in the market.

Therefore, developing a new vertical wheel repair lathe that meets modern enterprises’ demands for high efficiency, high precision, multifunctionality, ease of operation, and low cost will be an important direction for the development of the wheel repair and refurbishment industry.

The UK customer John found us on our company website and learned that we are a professional manufacturer of wheel repair lathes. He inquired if we could customize a new vertical wheel repair lathe to solve the problems he encountered in his business.

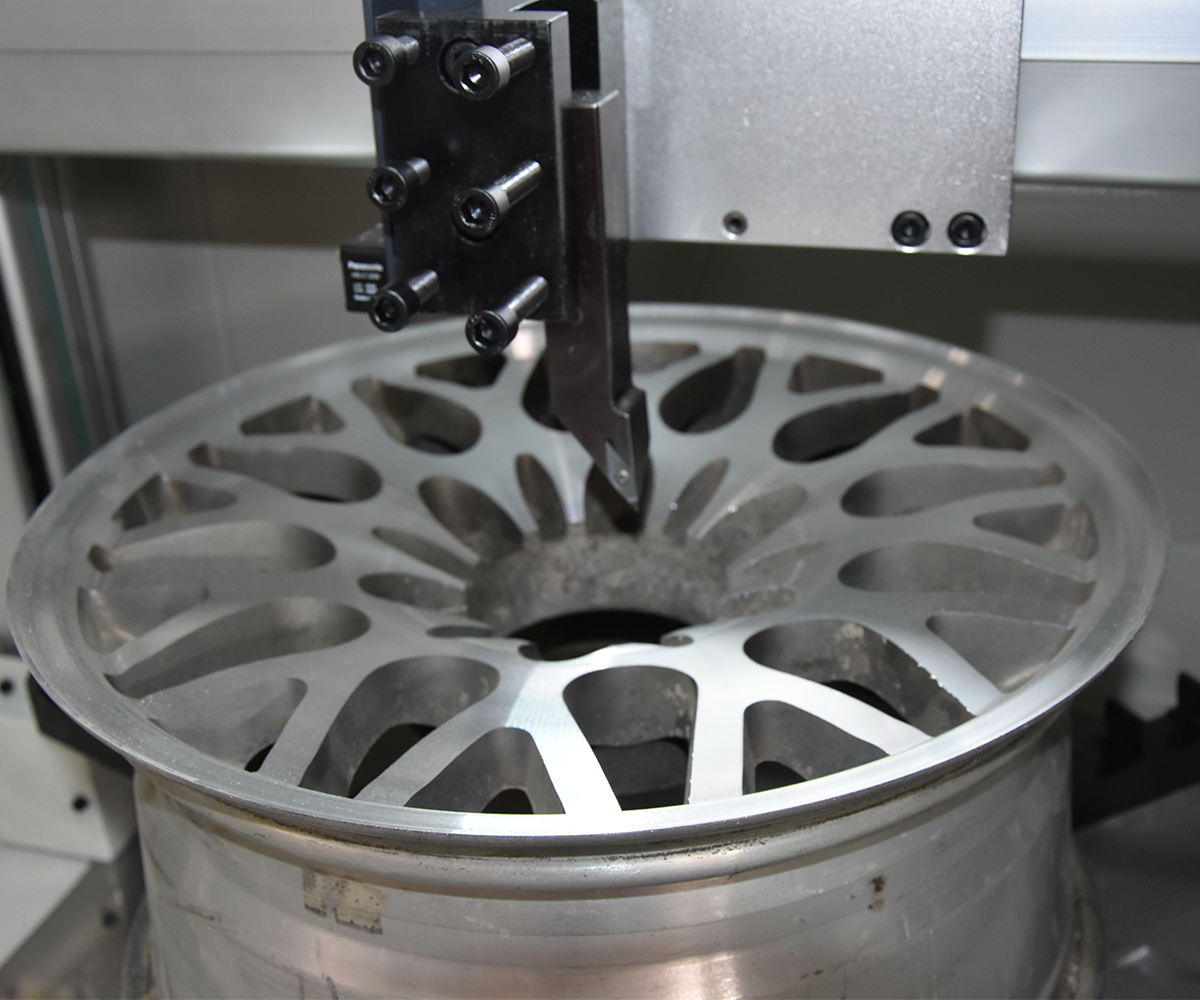

After understanding John’s needs and requirements, our engineers and technicians collaborated to design and develop a new vertical wheel repair lathe. This new machine uses Haishu’s independently developed specialized wheel repair system and employs laser detection. With the use of shape-mimicking functions, it can quickly grasp the curves on the surface of the wheel hub in just 15 seconds, solving John’s operational pain points.

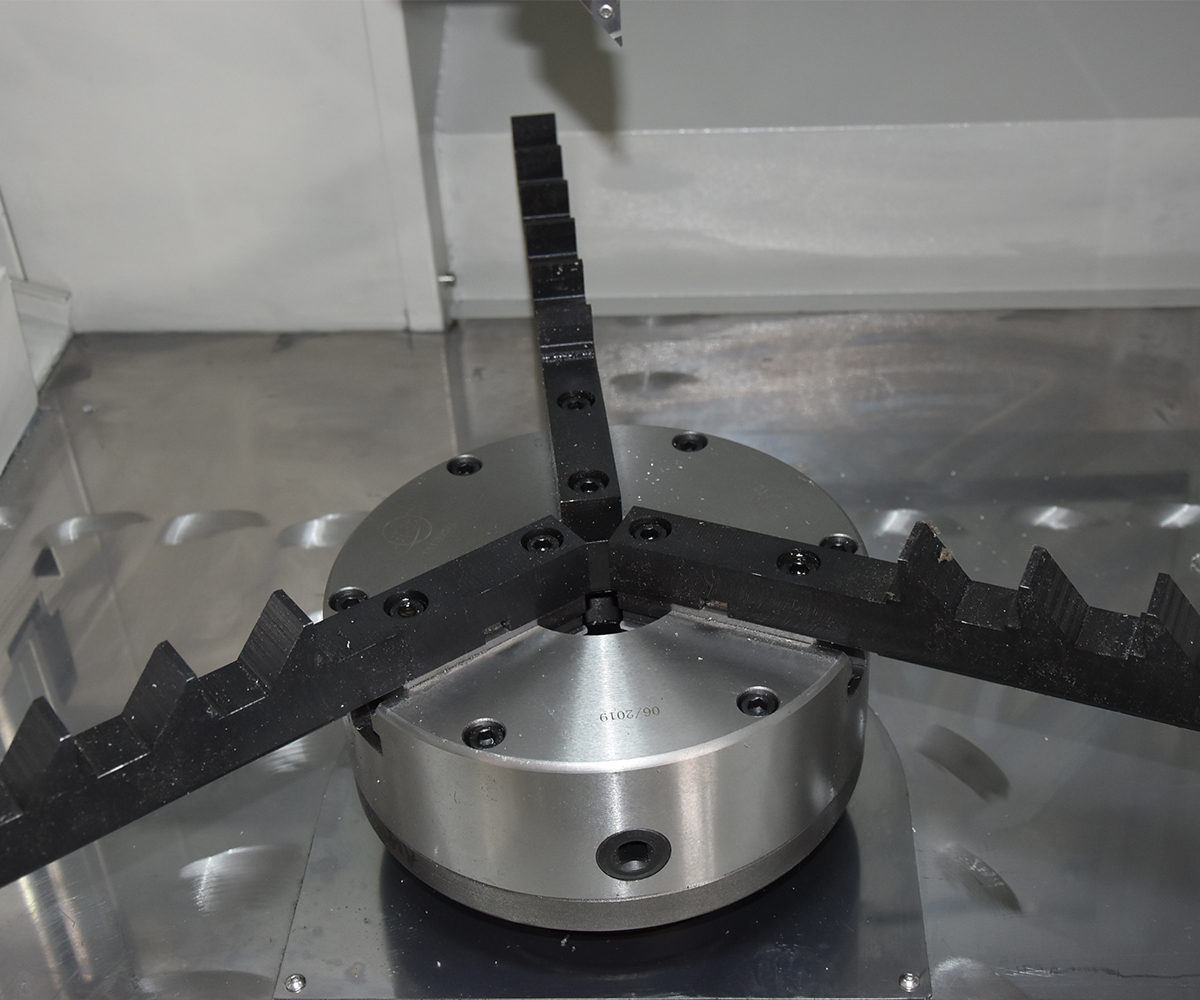

We also provided John with information on other improvements to the new vertical wheel repair lathe, such as replacing the regular spindle with a spindle assembly for more stable rotation. We changed the clamping method of the wheel repair lathe, using precision wire cutting technology to create dedicated fixtures that improve clamping efficiency and reliability. John was highly satisfied with our customized solution and decided to place an order with us.

As a professional manufacturer of wheel repair lathes, we are committed to providing customers with high-quality, customized products that meet their specific needs. By leveraging our expertise in design, engineering, and manufacturing, we have proposed the following transformation plan for our customers. We replaced the traditional hard rail with a linear guide rail to reduce friction, increase transmission speed, and improve the surface finish of the machined wheel hub by four times. Moreover, to ensure the new vertical wheel repair lathe’s structure is more robust, we adopted a gantry-type structure with dual columns to maintain rigidity even when repairing large wheel hubs. For overall aesthetics, we used high-strength alloys to completely overturn the traditional cast iron model, adding to the machine’s beauty while meeting the rigidity requirement.

We have incorporated various advanced technologies and components in the customized new vertical wheel repair lathe we designed for John, which has left him pleasantly surprised and satisfied. Our design features a pneumatic door structure that can be controlled through a foot pedal switch after clamping the wheel hub. The double cylinder mode ensures that the door stays securely closed, preventing any incidents of door detachment. Safety is our top priority, and we have installed an alarm device on the door to alert the system automatically in case the door is opened during processing, causing the new vertical wheel repair lathe to stop rotating and processing. This design perfectly aligns with the personal safety concept of European and American countries. Additionally, we have added three-color lights to facilitate real-time monitoring and control of the lathe’s status by operators, enabling efficient management and time-saving. The handheld wheel design enables more precise and convenient operation, with speed settings that can achieve precise adjustments at the micrometer level, making it efficient and precise in repairing and processing the wheel hub surface. We have also used an air cooling system that effectively blows away aluminum chips during processing, preventing scratches on the surface of the polished wheel hub due to aluminum chip residue. Furthermore, we have added LED lights to the wheel repair lathe, providing operators with good visibility. These LED lights can also be controlled by parameters, allowing them to be turned off during the day and turned on at night, achieving environmental protection and reducing electricity consumption while providing customers with a bright working environment.

To ensure the smooth operation of the new vertical wheel repair lathe, we have installed an automatic lubrication pump to ensure that all components are adequately lubricated. Additionally, we have upgraded the system’s parameter settings, allowing each component to be modified and adjusted through parameters to meet different operational requirements and working modes. These applications of advanced technologies and components make John’s new vertical wheel repair lathe more intelligent and efficient, enabling him to complete his tasks more easily in his daily operations.

In addition to incorporating advanced technologies and components in our new customized vertical wheel repair lathe, Tai’an Haishu Machinery Manufacturing Co., Ltd. has also upgraded the operation software to further enhance customer satisfaction. The new operation software features one-click detection, optimization, program generation, tool setting, and machining capabilities, allowing customers to master its operation within just 30 minutes.

With the one-click detection function, the system can quickly detect the shape and dimensions of the wheel hub, avoiding measurement errors and saving time. The one-click optimization function automatically optimizes the generated machining curve based on the detected data, ensuring a more precise and accurate machining path that closely adheres to the actual wheel hub contour. The one-click program generation function can automatically generate the machining program based on the optimized parameters, reducing the need for manual programming and lowering the technical requirements for the operator. The one-click tool setting function enables easy and precise tool setting, ensuring that the tool position is accurate and avoiding potential damage to the wheel hub. With the one-click machining function, the system can automatically execute the program, ensuring efficient and precise processing without requiring manual intervention.

These software upgrades make our new customized vertical wheel repair lathe more precise, efficient, and easy to operate, ultimately reducing labor costs and improving productivity. At Tai’an Haishu Machinery Co., Ltd., we are committed to providing high-quality and user-friendly wheel repair lathes that incorporate advanced technologies and components to enhance product performance and customer satisfaction.

After listening to Tai’an Haishu Machinery Co., Ltd.’s customized design of a new vertical wheel repair lathe for John, he expressed his respect for the company’s professionalism and high standard qualities. He stated that the design and manufacturing of the new vertical wheel repair lathe exceeded his expectations and demonstrated the company’s expertise and technical strength. John was highly satisfied with the efficient, precise, and safe performance of the wheel repair lathe and believed that it would make his work easier and more efficient.

John also praised Tai’an Haishu Machinery Co., Ltd.’s customer service, describing it as very professional and attentive. The company’s technical staff maintained close communication with him during the design and manufacturing process, promptly responding to his needs and feedback, and providing detailed guidance on operation and maintenance. John expressed his gratitude for the company’s support and cooperation and was willing to recommend the company to others.

After signing the contract with John and receiving his deposit, Tai’an Haishu Machinery Co., Ltd. completed the customization of the product for the customer in just 35 days. The company also invited John to the site for acceptance inspection, and he was very satisfied with the new customized vertical wheel repair lathe. During the inspection, John carefully examined the lathe’s performance and features and provided some valuable suggestions. The company’s professional technical team carefully listened to his opinions and promptly made adjustments and improvements.

After completing the acceptance inspection, John immediately expressed his desire to become Tai’an Haishu Machinery Co., Ltd.’s exclusive agent in the EU and signed an agency agreement. He believed that the company’s product quality and service level were excellent and that their prices were also very competitive. He was confident that both parties would be able to achieve fruitful results in future cooperation.

Since then, John has been ordering two containers of the new vertical wheel repair lathe every month and selling them to customers in the EU. He has always maintained a high level of trust and recognition for the company’s products and services, and is willing to provide active support and assistance for the company’s expansion in the EU market. If you would like to know John’s contact information, we would be happy to provide it for you.

Tai’an Haishu Machinery Co., Ltd. will continue to adhere to the principles of professionalism, innovation, integrity, and service, and provide better products and services to customers. We are committed to establishing long-term and stable relationships with customers and partners, and achieving win-win cooperation.

We are sharing this story to better introduce the characteristics of Tai’an Haishu Machinery Manufacturing Co., Ltd. We are committed to custom design and manufacturing according to our customers’ requirements, while also helping them perfect and optimize their desired products. Our mission and values are to establish long-term cooperative relationships, become friends through business, and prioritize everything for our customers.

Currently, our company is continuing to develop a new type of wheel repair lathe, a CNC wheel repair lathe specifically designed for German users. If you are interested, please continue to follow our website, and we welcome you to contact us at any time to learn more.

Our company has always adhered to the principles of professionalism, innovation, integrity, and service, and is committed to providing better products and services to our customers. We believe that through continuous research and development and continuous innovation, we will be able to meet the ever-changing needs and challenges of our customers.