What Makes the New Wheel Repair Lathe in the UK a Game-Changer?

The new wheel repair lathe in the UK has a very broad automotive repair market prospect. This advanced wheel repair machine can be utilized in various industries. Let’s explore why this new wheel CNC machine is set to revolutionize the market.

Why is the wheel refurbishment lathe in the UK in High Demand?

- Rising Car Ownership: China’s car ownership has exceeded 283 million, making it a major car ownership country in the world.

- Wheel Hub Usage: In factory cars, 60% use spray wheel hubs, 30% use brushed wheel hubs, and 10% use plating wheel hubs.

- Increasing Demand for Brushed Wheels: The demand for brushed wheels is increasing at a rate of 20% per year.

- High Modification Rate: 60% of car owners will make a second modification.

- Popularity of Brushed Wheels: Personalized, advanced, and fashionable brushed wheels are increasingly popular among modern people.

- Common Wheel Damage: More than 65% of cars have wheel damage, making wheel repair a common necessity.

What Sets the New Wheel Repair Lathe in the UK Apart?

Conventional wheel repair machines have disadvantages such as requiring programming knowledge, complicated operations, difficulty in getting started, a single detection mode, and poor repair accuracy. In contrast, the fully automatic, program-free, three-detection system of the wheel repair lathe in the UK will be more popular in the market!

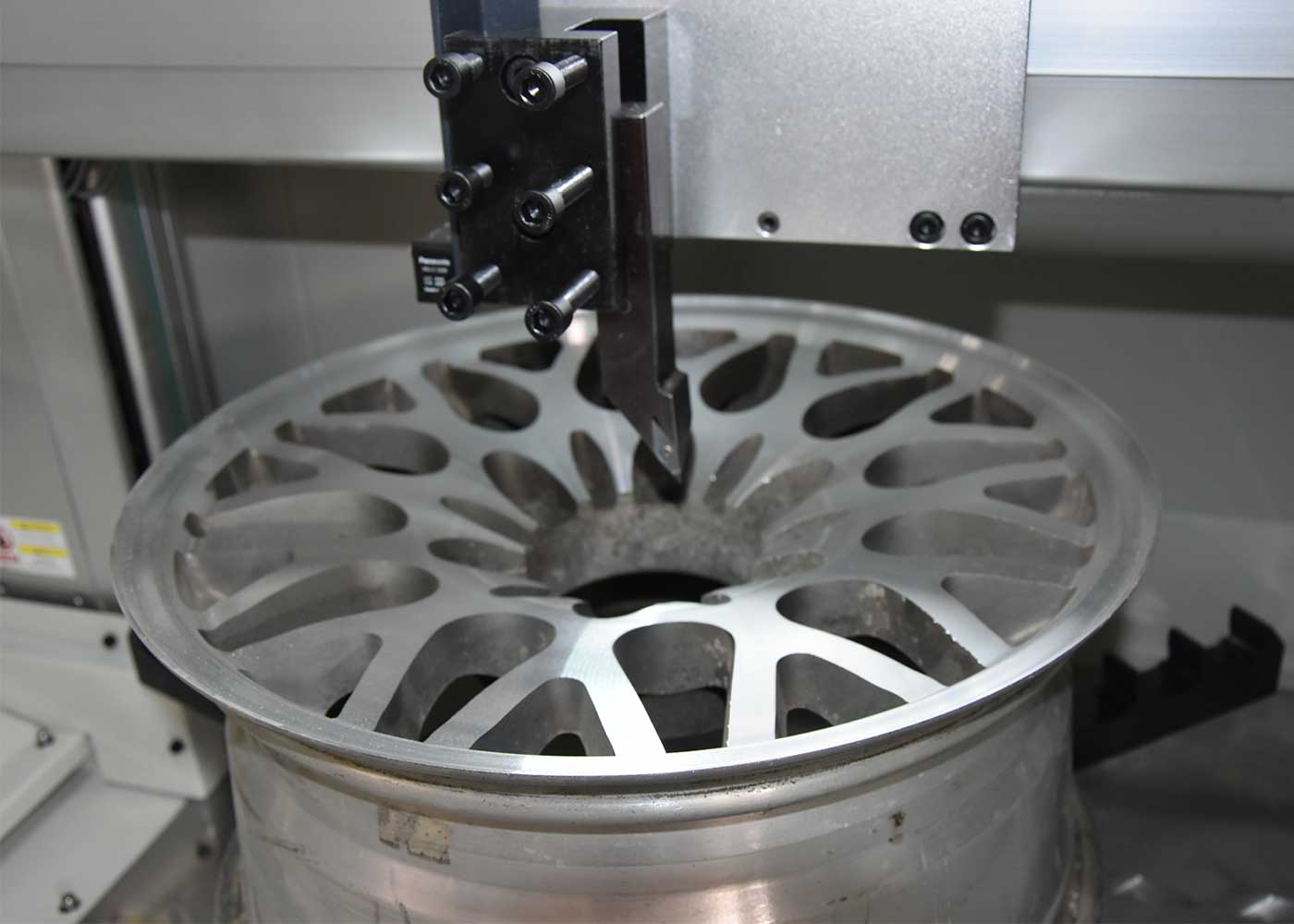

To meet customers’ demands for more economical and practical solutions, our company developed the vertical wheel repair lathe CKL-35. This new wheel CNC machine has a maximum wheel size of 35 inches but is priced at just 80% of the same specification horizontal lathe. Its performance surpasses that of traditional horizontal wheel CNC lathes.

How Does the New Wheel Repair Lathe in the UK Improve Efficiency and Quality?

The new wheel CNC machine CKL-35 is a mature product confirmed by British customers. They initially ordered one prototype for an exhibition and now have over 10 orders. This success underlines the product’s market potential. This alloy wheel lathe is the first vertical wheel hub repair lathe in China, keeping our products ahead of the competition.

Key Features of the New Wheel Repair Lathe CKL-35:

- Advanced Design: The vertical structure offers more stable mechanical transmission, better-turning performance, and higher machining precision.

- Versatile Range: Suitable for wheels up to 35 inches in diameter, with a compact footprint and strong professional capabilities.

- User-Friendly: Self-developed software with an LCD touchscreen simplifies surface measurements and program optimization.

- Flexible Measurement Options: Laser or probe contact measurement options, with fast scanning capabilities.

- Teaching Function: Allows for full or partial wheel surface repairs.

- Precision and Stability: Dual servo motor drives, precise linear guide rails, and a high-precision spindle unit ensure reliable performance.

- Optimized Data Handling: Wheel measurement data curves can be optimized automatically or manually.

- Comprehensive After-Sales Support: Includes software upgrades and remote technical training via the machine’s network interface.

What Are the Technical Specifications of the New Wheel Repair Lathe in the UK?

Technical Parameters:

- Max. Turning Diameter: 1000 mm

- Max. Machining Wheel Diameter: 35 inches

- Chuck Max. Clamping Diameter: 680 mm

- Main Motor Power: 5.5 kW

- Turret Form: 2-station row turret

- Machine Weight: 1500 kg

- Machine Size: 2000×1550×2000 mm

The new wheel repair lathe CKL-35 is designed for the repair and processing of the wheel surface, center hole, and rim. As a professional CNC machine designer and manufacturer, Taian HAISHU Machinery Co., Ltd offers high-quality and innovative CNC wheel machines, including wheel repair lathes, wheel repair machines, and other customized CNC equipment. Our products are ahead of the competition, ensuring your wheel repair business stays at the forefront of the industry. For any inquiries, please contact us, and we will respond promptly.