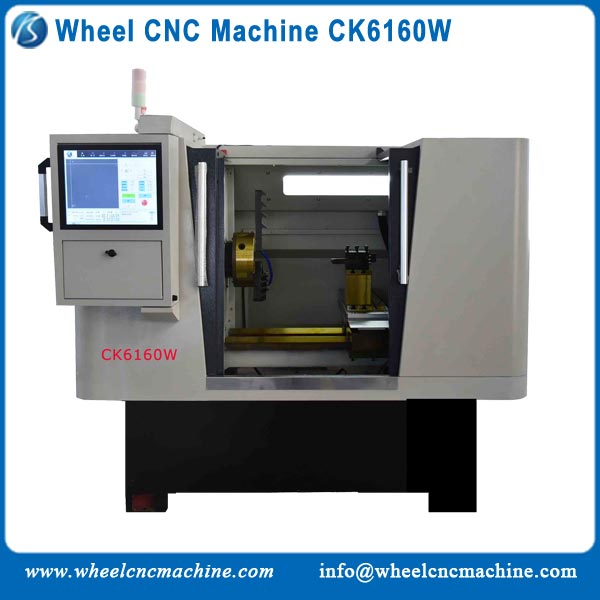

Alloy wheel lathe features an integrally cast bed structure that adds rigidity to the wheel repair lathe. At the same time, it has been reduced in size and is a compact wheel lathe. The alloy wheel lathe features automatic detection and precise optimization, which can achieve a variety of processing effects on the surface of the aluminum alloy wheel.

Alloy Wheel Lathe With Laser Probe

Description

Alloy wheel lathe CKL-35 is a CNC vertical wheel lathe designed to meet the needs of automotive wheel hub machining. The machine tool adopts single-spindle and double-tool frame structure, and the loading and unloading device adopts double-station rotary exchange table, which has high production efficiency and processing precision and is suitable for wheel processing with large batch size, high processing precision and good dimensional consistency. Various precision indicators meet or exceed the level of similar foreign machine tools, and are the first choice for the automotive industry to process wheel parts. The machine is suitable for machining 16-35 inch wheels.

This alloy wheel lathe features a gantry-style motion frame with a total of three servo motor controls and a double column with a beam. The material is made of alloy material, which increases the rigidity while reducing the weight and is also beautiful. The alloy wheel lathe produced by our company are developed, designed, produced, manufactured and sold. We can customize the wheel repair lathe for customers, and it is a professional wheel lathe manufacturer. At the same time, we have a variety of patents, and CE certification of the European Union, the products have been exported to more than 60 countries.

alloy wheel lathe with laser probe

Alloy Wheel Lathe CKL-35 Specifications

| Item | Unit | Specifications |

| Model | CKL-35 | |

| Max.turning diameter | mm | 1000 |

| Max.machining wheel diameter | mm | 900(35”) |

| Chuck maximum clamping diameter | mm | 920 |

| Spindle speed | rpm | 50-1200 |

| Turret form | 2 station row turret | |

| Cutting feed rate | mm/min | 0.1-1000 |

| Tool handle section | mm | 25×25 |

| Main motor power | KW | 5.5 |

| Machine weight | Kg | 1500 |

| Machine Size | mm | 2000*1500*2000 |

Alloy Wheel Lathe CKL-35 Features

- Newly developed Vertical Wheel Repair Lathe by HAISHU Machinery for alloy car wheel repair and super finishing.

- Cast iron bed. The wheel repair CNC lathe bed is made of cast steel in vertical structure.

- Large wheel processing diameter. The max wheel processing diameter is up to 35 “.

- Self-developed special wheel repair control software. Automatic wheel surface measurement and program optimization can be realized simultaneously.

- Laser non-contact measurement or probe contact measurement are optional. Laser measurement enables fast scanning.

- Teaching function. The overall wheel surface of can be repaired, but also can be partially repaired.

- LCD touch screen configuration

- Compared with the horizontal structure, the mechanical transmission is more stable, the turning performance is better and the machining precision is higher.

- Small machine tool space, professional CNC lathe for wheel repair.

- Professional after sale service including software free upgrade and remote operation and technical training on the machine’s LCD display.

- High performance, cost effective.

- Easy to operate and maintain.

wheel lathe with laser probe

About HAISHU Machinery

As a company specializing in the production of alloy wheel lathe, Taian Haishu Machinery Co., Ltd. has manufactured more than 10 wheel CNC lathe and exported them to more than 60 countries. For example, EU countries, South Korea, Australia, New Zealand, Vietnam, Greece, etc. Our company also produces products related to wheel lathes, such as wheel straighteners, grilled tire machines, dynamic balancing machines, lifts and more. Our company has a particularly strong R&D capability and has designed advanced tools such as electric tool holder rotation and laser detection to repair alloy wheels. Buying our wheel repair lathe will make it easier and faster to repair your car’s wheels.