Description

Newest Wheel Repair Lathe

1. Introduction

Background

The Wheel Repair Lathe, addressing everyday wheel rim damage from rough roads, accidental impacts, adverse weather, and regular wear, offers an economical alternative to costly wheel replacement. This innovation not only preserves vehicle performance but also maintains aesthetics, leading to a growing demand for efficient wheel repair solutions in the automotive market.

Purpose

The Wheel Repair Lathe is a sophisticated tool designed to provide cost-effective and user-friendly wheel repair services. This wheel CNC machine saves on the expenses associated with wheel replacement and streamlines the repair process with its precision and speed. Not only does it bolster vehicle safety and increase its resale value, but it also contributes positively to the environment by reducing waste. The versatility and customization capabilities of this wheel repair machine enhance its appeal in the automotive repair industry, marking it as a vital asset for boosting service quality and market competitiveness

.

2. Product Overview

Definition

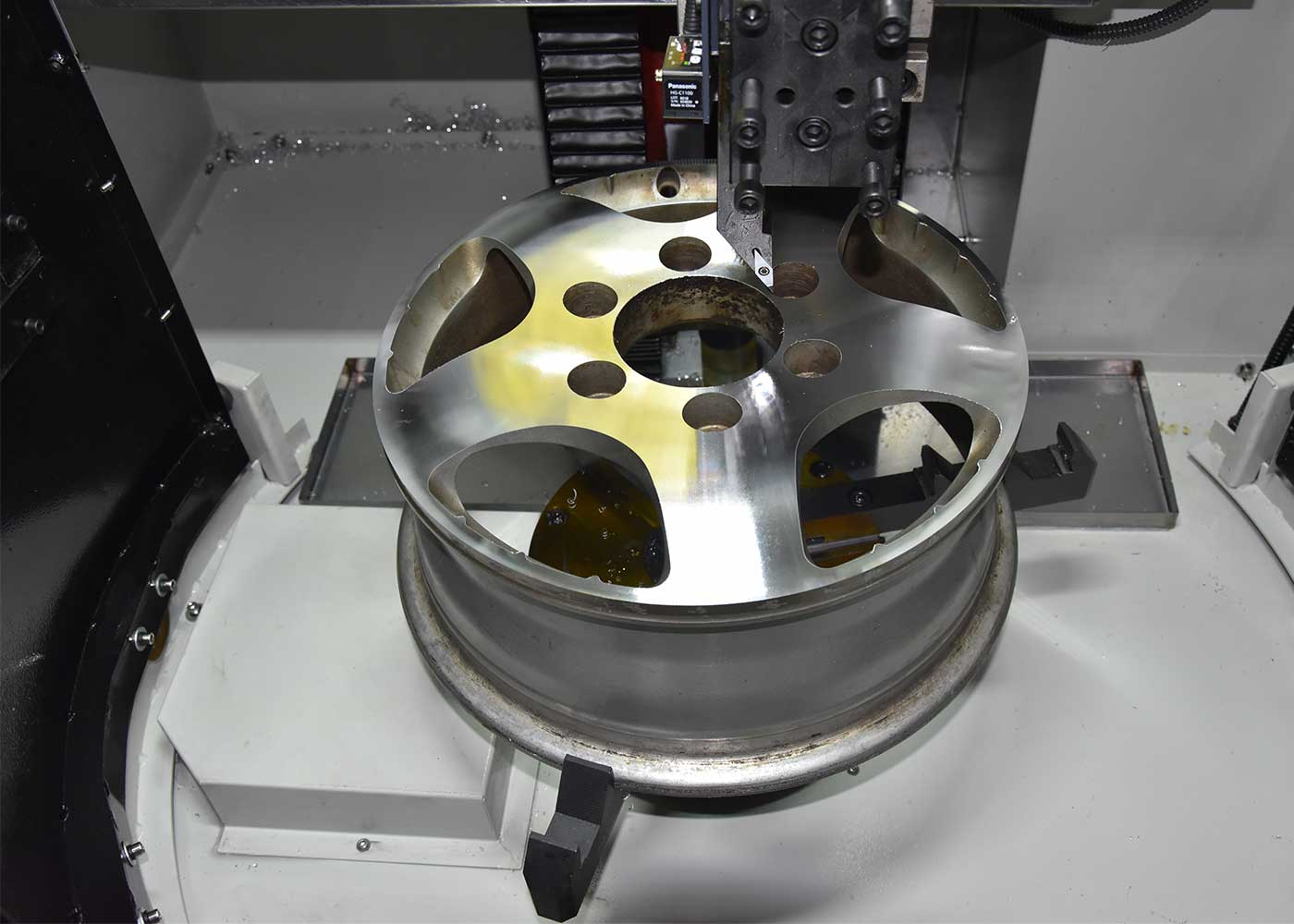

A Wheel Repair Lathe is a CNC machine tool specifically designed for repairing damaged wheel rims. It accurately diagnoses and measures the wheel, and then crafts a tailored repair program to guide the cutting tool. This tool systematically removes damage, and if necessary, performs polishing and coating to improve the wheel’s appearance. The goal is to restore the wheel rim efficiently to near-original condition, ensuring both quality and precision, while also being cost and time-effective.

Key Features

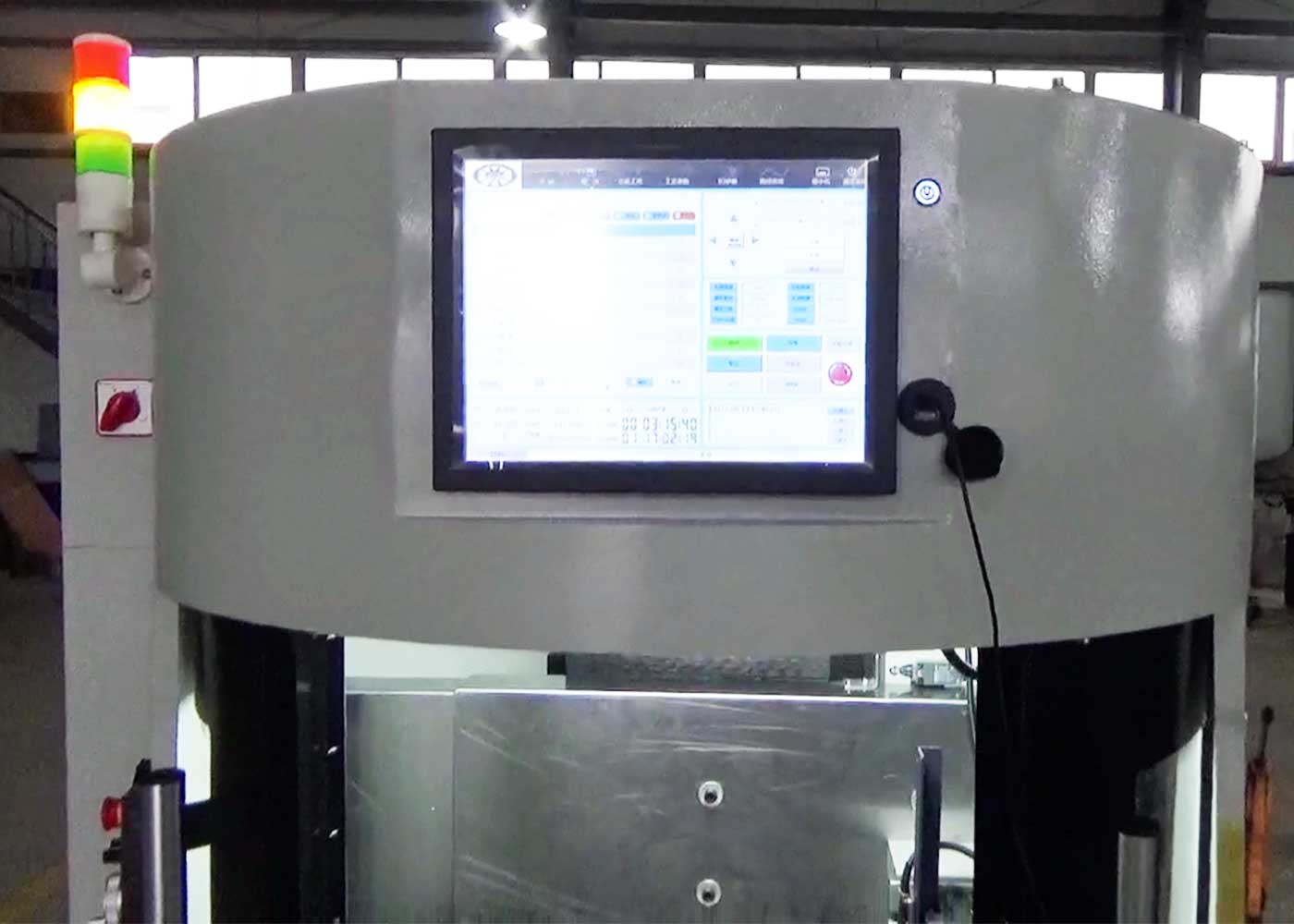

The Wheel Repair Lathe’s principal characteristics include a vertical structure that allows for the wheel to lie flat on the clamping fixture, which minimizes the centrifugal force encountered when clamping wheels upright. It features specialized rim clamps with extended jaws tailored for wheel shapes, ensuring a firm grip on the wheel rim. A 17-inch touchscreen interface equipped with a dedicated wheel repair system provides a high level of automation, simplifying operations so that even novices can quickly become proficient.

3. Technical Specifications: Translate This Sentence Into English.

| NO. | Item | Unit | Technical Parameters |

| 1 | Max. turning diameter | mm | 660 |

| 2 | Max. machining wheel diameter | mm | 610 (24”) or 660 (26”) |

| 3 | Chuck maximum clamping diameter | mm | 620 |

| 4 | Spindle speed(frequency conversion) | rpm | 50-1200 |

| 5 | Cutting feed rate | mm/min | 0.1-1000 |

| 6 | Turret vertical movement distance | mm | 380 |

| 7 | Turret horizontal movement distance | mm | ±310 |

| 8 | X-axis fast-moving speed | mm/min | 3000 |

| 9 | Z-axis moving speed | mm/min | 3000 |

| 10 | Turret form | 2 station row turret | |

| 11 | Tool handle section | mm | 25×25 |

| 12 | Main motor power | kw | 3.0 |

| 13 | Feed motor | X: 6Nm Z: 10Nm | |

| 14 | Machine positioning accuracy | mm | 0.015 |

| 15 | Machine repeated positioning accuracy | mm | 0.012 |

| 16 | Machine gross weight | kg | 1000 |

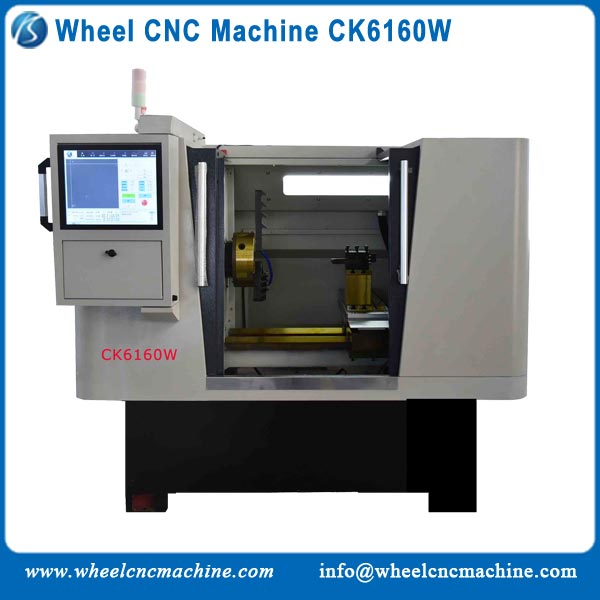

| 17 | Machine dimensions | mm | 1330×1260×1800 |

vertical rim repair lathe

4. Innovative Design and Advanced Features of Wheel Repair Equipment

Ergonomic Structural Design

The Vertical Alloy Wheel Repair Machine revolutionizes the traditional lathe design with an emphasis on vertical integration, providing a space-saving solution that enhances the rim repair process. This design streamlines the workflow, making it more efficient for operators to manage tasks such as loading, unloading, and tool changes. A clean working area is ensured by the vertical set-up which is beneficial for chip and debris disposal, thereby optimizing wheel refinishing results.

Multi-functional Capabilities in Rim Refurbishment

- Precision CNC Wheel Lathe Technology: This technology allows for detailed programming and automated control, making it a key feature in alloy wheel lathe operations.

- Automated Detection and Diagnostics: Advanced scanning identifies imperfections, facilitating a precise rim refurbishment process.

- User-Friendly Interactive Controls: The machine often includes features like touchscreens to improve the user interface, making the operation of the rim refurbishment machine more intuitive.

- Multi-Axis Adaptability: Critical for addressing complex repairs and ensuring a high-quality finish from a wheel refinishing machine.

- Automated Tool Changer: Enhances productivity by reducing manual input during the repair cycle.

- High-Precision Refinishing: The machine’s accuracy ensures that refurbished wheels meet original quality standards.

- Quick Adjustment Features: Rapid configuration is essential for reducing downtime in busy wheel polishing operations.

- Energy-Efficient and Environmentally Friendly: The design focuses on reducing power consumption and operating quietly, which benefits rim repair equipment providers.

- Robust Safety Standards: Safety features are paramount, particularly when it comes to wheel polishing tasks, which can be hazardous without proper precautions.

5. Real-World Applications and Market Impact

Broad Market Adaptability

The HAISHU Vertical Alloy Wheel Lathe is suited for a variety of market segments:

For Dedicated Rim Repair Services:

- Space-Efficient Design: Fits well in smaller shops, providing full functionality without requiring a large footprint.

- Easy-to-Use Interface: A user-friendly interface on the rim refurbishment machine enhances operational efficiency.

- Adaptable to Various Wheel Sizes: The machine can handle a range of wheel dimensions, which is important for shops servicing different vehicle models.

For Auto Manufacturing and Refurbishing Facilities:

- High-Precision CNC Wheel Lathe: Essential for ensuring wheel quality aligns with OEM standards.

- Streamlined Production: Minimizes cycle times, which is crucial in a high-volume production environment.

- Durable Construction: The alloy wheel repair machine is designed for continuous, heavy-duty use.

- Versatile Wheel Polishing Machine: Offers flexibility to accommodate different wheel finishes, integrating well with manufacturing processes.

In summary, the HAISHU Vertical Alloy Wheel Repair Machine is designed to be user-friendly and space-efficient, suitable for both specialized rim repair shops and larger automotive manufacturing setups due to its precision and automated capabilities.

Customer Success Stories with CNC Lathe Technology

Including testimonials that vouch for the machine’s performance and the advanced CNC technology used in wheel repair equipment can reinforce the value proposition to potential customers.

6. Quick Overview: Automated Wheel Repair Lathes

Effortless Operation with CNC Technology

HAISHU CNC Lathes streamline wheel repairs with intuitive touchscreens and simplified workflows, reducing training time and enhancing shop productivity.

Automation at Its Best

Automated Detection and Repair Functions in our Wheel Restoration Machines cut down on manual labor and speed up the repair process.

Success Stories: Efficiency in Action

Transforming Repair Shops

Shops utilizing HAISHU Lathes report faster repairs, lower training costs, and heightened customer satisfaction.

Dealerships Drive Revenue

Dealerships offering quick, on-site repairs with our CNC Lathes see an uptick in service revenue.

Support and Upgrades for Peak Performance

Uninterrupted Operations

With remote diagnostics and a well-stocked parts inventory, we minimize machine downtime.

Continuous Improvement

Regular software and hardware updates ensure your wheel repair lathe stays ahead of the curve.

For high-efficiency wheel repair solutions, HAISHU’s Automated CNC Lathes are the industry standard.

7. Economic Benefits of Utilizing Wheel Repair Lathes

Comparing the costs of repairing versus replacing wheels reveals that wheel repair is generally less expensive than buying new rims. The Wheel Repair Lathe is a cost-effective solution that significantly reduces material and labor expenses, offering significant savings for businesses that frequently require such services.

Investing in a Wheel Repair Lathe presents potential economic benefits including:

Cost-Effective Repairs and Enhanced Efficiency

- Reduced Repair Costs: Lowering expenses and boosting efficiency, thus accelerating the return on investment (ROI).

- Expanded Service Offerings: Improving customer satisfaction and attracting additional business by broadening service capabilities.

- In-House Services: Saving costs that would otherwise be spent on outsourcing to third parties.

- Long-Term Asset Stability: Lowering maintenance overhead and preserving the residual value of the equipment through reliable, long-term usage.

8. Safety and Environmental Impact of Wheel Repair Lathes

Ensuring Operator Safety and Compliance

The safe design features of Wheel Repair Lathes, including emergency stop buttons, protective shields, safety locks, sensors, and overload protection, ensure operator safety and compliance with industrial safety standards. Additional safety considerations like anti-slip floors, noise control, dust management, and professional training are integrated to secure a safe working environment.

Positive Environmental Contributions

Opting for wheel refurbishment over replacement has a positive environmental impact by conserving resources, reducing waste production, enhancing energy efficiency, lowering the carbon footprint, and minimizing pollution during the production process. These eco-friendly advantages align with the principles of a circular economy, contributing to sustainable development goals.

9. Conclusion: Revolutionize Wheel Repair with Our CNC Technology

As a leading manufacturer of Wheel Repair Lathes, we take pride in offering a solution that marries cost-efficiency, high performance, and eco-friendliness. Our Wheel CNC Machines are meticulously engineered to help clients broaden their service range with fast, reliable wheel refurbishing services, while also diminishing the dependency on new wheel production, hence supporting environmental sustainability.

Our Wheel Repair Machines are crafted for durability and extended service life, ensuring a reduction in maintenance expenses. We are dedicated to assisting our clients in reducing their carbon footprint and achieving sustainable business practices.

We invite businesses looking to elevate their wheel repair services, increase operational efficiency, and embrace eco-friendly solutions to connect with us. Arrange a demonstration of our Wheel Repair Lathe or speak with our sales team to tailor solutions to your specific needs. Let us be part of your journey to success, helping you to navigate towards a more sustainable and profitable future with our state-of-the-art Wheel CNC Machine technology.

For a greener, more efficient tomorrow, choose our Wheel Repair Machines. Contact us now for a consultation and see the difference our equipment can make in your wheel repair services.