Description

Wheel Repair Machine: The Key to Efficient Alloy Wheel Refurbishment

In today’s automotive service industry, the wheel repair machine has become an indispensable technology for the restoration of alloy wheels. Praised for their elegance, lightness, and performance benefits, alloy wheels are a popular choice among vehicle owners. However, they are not impervious to the wear and tear caused by uneven road terrain and the dreaded potholes that can result in damage, necessitating professional and precise repair work. This is where the integration of both wheel repair machines and wheel repair lathe technologies becomes vital, offering accurate and efficient solutions for wheel reshaping and refurbishment.

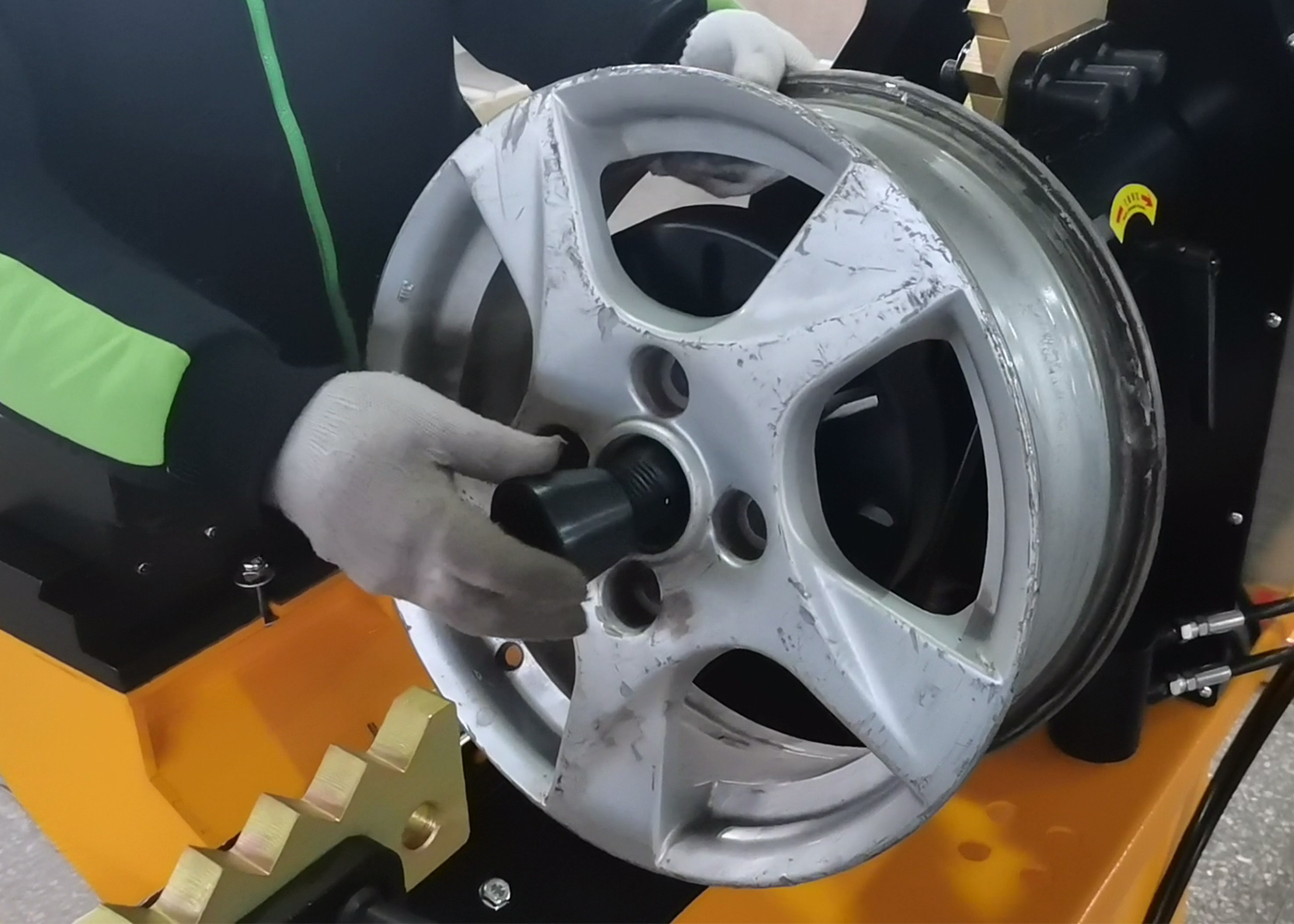

new wheel repair machine

1. How a Wheel Straightening Machine Works

A wheel straightening machine utilizes a sophisticated hydraulic system, featuring tools and an automatic rotation function, to accurately mend bent or damaged alloy wheels. Technicians can finely tune the process, applying controlled force with hydraulic pistons around the rim edges to correct distortions. This not only mitigates the necessity of replacing original alloy wheels but also conserves both time and resources for car owners.

| Item | Technical Parameters |

|---|---|

| Machining capacity | 10"~26" |

| Working pressure | 10000kg |

| Motor power | Mechanical 0.55kw. Hydraulic 0.75kw. |

| Power | AC single phase 220V/ three phase 380V 50Hz |

| Packed size | 1320×780×1420mm |

| NW/GW | 325kg/365kg |

Efficiency in Wheel Repair

The repair process for a wheel using a wheel straight machine is both time and cost-efficient. An adept technician can complete a standard straightening job within 25 to 35 minutes, though the duration may vary with the severity of the wheel’s damage.

2. Precision with Wheel CNC Machine

The integration of a wheel CNC machine into the wheel repair workflow introduces unmatched precision, ensuring the reshaped wheel closely matches its factory specifications. With computer numerical control (CNC), these machines produce results with utmost accuracy, essential for maintaining the wheel’s performance and safety standards.

Saving Time and Money

Employing a wheel repair lathe significantly cuts down on repair time, offering a cost-effective alternative to wheel replacement. This efficiency not only benefits the repair service providers but also extends to vehicle owners, who save on potential long-term expenses.

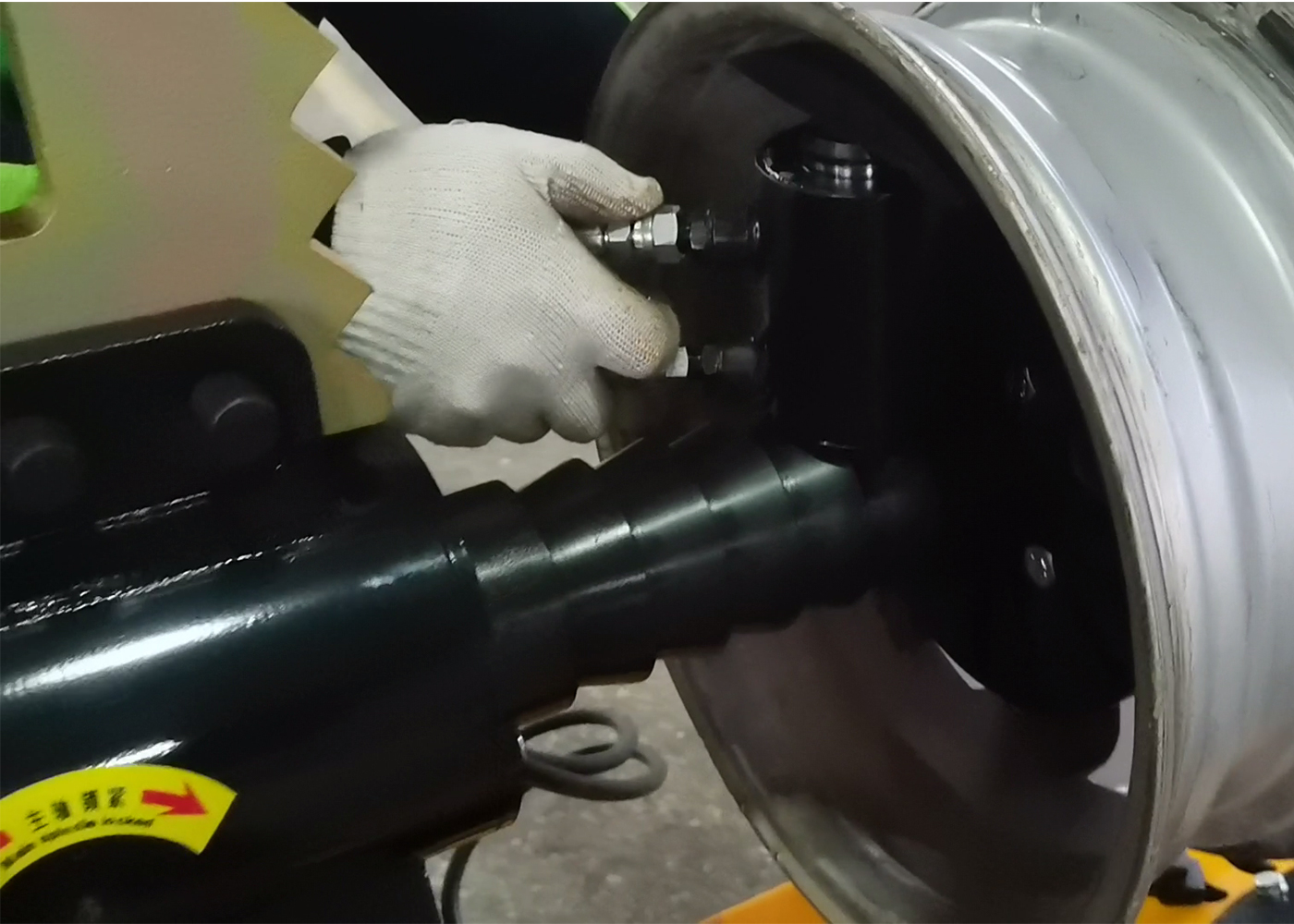

wheel straighting machine

3. Final Thoughts: The Benefits of a Wheel Repair Lathe

A wheel repair lathe is more than just a tool for fixing alloy wheels—it is a testament to the advancements in automotive repair technology. By ensuring the safety, enhancing performance, and preserving the aesthetics of alloy wheels, these machines offer a dependable remedy for wheel damage.

newest wheel repair machine

Compact Wheel Repair Machine: The Ultimate Solution for Modern Workshops

1. Space-Saving Design and Mobility

The wheel repair machine introduces a compact and efficient design, ideal for integrating into any workshop, even those with limited space. Its portability is unparalleled, easily fitting into vans for mobile alloy wheel repair services, making it a versatile choice for businesses.

2. Innovative Noise Reduction

Ultra-Quiet Operation

Advanced noise reduction technology ensures the wheel CNC machine operates almost silently, offering a more flexible and pleasant workplace environment.

3. User-Friendly and Durable

Easy Operation

As the simplest wheel straight lathe on the market, it offers straightforward operation with minimal training required. Its tested durability guarantees long-term stability, reducing the risk of downtime.

alloy wheel repair machine

HAISHU Series: Advancing the Wheel Rim Repair Industry

1. CNC Machine Innovation

HAISHU’s CNC machines are transforming the wheel rim repair industry with innovative diamond cutting repair machines and the first-of-its-kind, vehicle-mounted wheel hub repair lathes, tailored for both stationary workshops and agile mobile repair units.

2. The Ultimate Efficiency Tool

The alloy wheel straightening machine by HAISHU is an invaluable asset for enhancing operational efficiency and ensuring high levels of customer satisfaction, engineered for ease of use and consistent performance.

3. Join Our Global Network

We invite partners worldwide to join the HAISHU business network, where we offer top-tier products and collaborative market growth strategies. Let’s build mutual success.

Connect with us for a prosperous partnership.