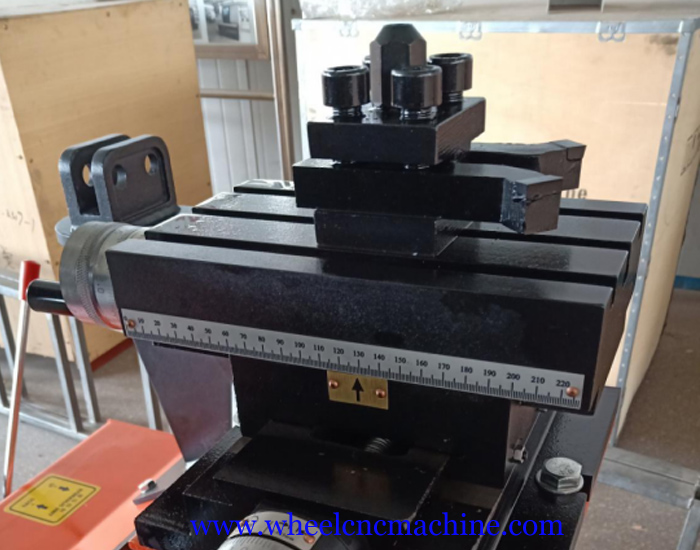

RSM595 Rim Repair Lathe Machine for Efficiently Repairing Various Aluminum Alloy Wheels

The RSM595 Rim Repair Lathe Machine is the ultimate solution for repairing various types of aluminum alloy wheels. With its unique design and standard shaping effect, this automatic rim straightening lathe offers a simple and efficient operation process. It can repair distortions, depressions, and deformations in aluminum alloy wheels ranging from 10″ to 26″ in diameter.

Equipped with an easy-to-operate hydraulic unit, the RSM595 Rim Repair Lathe Machine ensures precise control and positioning without causing any damage to the aluminum alloy’s molecular structure or mechanical properties. Through heat treatment and artificial aging, damaged wheels can be quickly restored to their original shape. The machine’s infinitely variable speed function (0-300r/min) further enhances its versatility and efficiency in tasks such as offset detection, positioning marking, plastic repair, lathe cutting, and mirror polishing.

Not limited to shaping and correction, this advanced lathe machine can also handle edge processing, surface planing, and other intricate tasks related to aluminum alloy wheel repairs. It is the go-to equipment for resellers like Mr. Mohamod from Kuwait, who visited our factory to explore wheel repair CNC machines. After careful consideration, he decided to purchase the RSM595 wheel straightening machine and the CK6160W wheel repair lathe, signifying their effectiveness and reliability.

Following a 20-day manufacturing period, we successfully completed the RSM595 wheel repair lathe. Mr. Mohamod expressed satisfaction upon reviewing the pictures and working video we provided, showcasing the capabilities of the wheel straightening machine. We are now preparing for the machine’s packaging and timely delivery to ensure a seamless experience for our valued customer.

Daily Maintenance and Key Features of Rim Repair Lathe Machine RSM595

Regular cleaning and maintenance are crucial for ensuring the efficient and accurate operation of the Rim Repair Lathe Machine RSM595. Users should follow the guidelines outlined in the operation manual for routine maintenance procedures. Prior to cleaning or maintenance tasks, it is essential to turn off the main power and unplug the machine from the socket.

Daily maintenance involves cleaning and greasing the turntable and lathe components. Additionally, it is recommended to check the hydraulic system oil level on a monthly basis and tighten the screws of the lathe parts. Every six months, the bearings should be greased, and a comprehensive inspection of the machine should be conducted.

Key Features of Rim Repair Lathe Machine RSM595:

- RSM595 is an ideal machine designed for straightening and milling uneven areas of car rims within the diameter range of 10″ to 26″.

- It is specifically used for milling uneven spots that may occur after welding (welding machine not included).

- Optional configuration includes an electrical polisher, which can be used for achieving a smooth finish on the rim surface.

- The hydraulic cylinder exerts a pressure of 10,000 kg, providing ample force for the repair and restoration processes.

By adhering to proper daily maintenance procedures and utilizing its notable features, the Rim Repair Lathe Machine RSM595 ensures optimal performance and extends the lifespan of the equipment, facilitating efficient and precise repairs for a wide range of car rims.

Rim Repair Lathe MachineRSM595 Technical Parameters

| Item | Specifications |

|---|---|

| Machining capacity | 10"~26" |

| Working pressure | 10000kg |

| Motor power | Mechanical 0.55kw. Hydraulic 0.75kw. |

| Power | AC single phase 220V/ three phase 380V 50Hz |

| Packed size | 1320×780×1420mm |

| NW/GW | 325kg/365kg |

About Haishu Machinery

Taian Haishu Machinery Co., Ltd. is a reputable CNC machine designer and manufacturer that specializes in providing automobile wheel production and repair solutions to customers worldwide. Since 2001, we have been committed to establishing ourselves as a leading company in CNC lathe design and manufacturing. With a team of over 30 talented experts and a factory spanning more than 12,000 square meters, we pride ourselves on delivering innovative and high-quality products, including wheel CNC machines, wheel repair machines, brake drum lathes, and customized CNC machines.

Our focus has always been on product development, incorporating the principles of innovation, simplicity, high quality, and efficiency. Since our establishment in 2001, we have dedicated ourselves to CNC software development, structural design, process planning, manufacturing deployment, and quality control. Our extensive product range encompasses wheel CNC machines, alloy wheel CNC lathes, wheel repair machines, brake drum lathes, wheel straightening machines, alloy wheel lathes, alloy wheel polishing machines, rim straightening machines, brake disc lathes, and various other customized CNC machines. We have served customers from Germany, Russia, Spain, India, South Korea, Malaysia, Singapore, Saudi Arabia, South Africa, Iran, Indonesia, Turkey, Jordan, Dubai, Poland, Morocco, Mexico, Brazil, Lebanon, Thailand, Kazakhstan, Bangladesh, Hong Kong, Taiwan, and many other countries.

We are actively seeking partners worldwide to collaborate with us in driving our business forward.