Efficient Alloy Car Wheel Repair and Maintenance Solution

The Small Automatic Wheel Polishing Lathe CK6160Q is a specially designed CNC machine by Haishu Machinery, catering to the needs of alloy car wheel repair and maintenance in car repair workshops. This compact and efficient wheel CNC machine, CK6160Q, is equipped with a self-developed CNC system and offers a range of features that make it ideal for wheel repair operations.

The CK6160Q wheel repair lathe boasts a high level of efficiency, allowing for quick and precise repairs. Its compact structure ensures it can fit into smaller workshop spaces without compromising on performance. The machine features a user-friendly touch screen interface, making it easy to operate even for those with minimal experience.

One of the advantages of the CK6160Q is its lightweight design, making it highly portable and suitable for mobile repair services. Additionally, users have the flexibility to choose between a chuck or mandrel as a fixture, depending on their specific requirements.

With the Small Automatic Wheel Polishing Lathe CK6160Q, Haishu Machinery provides car repair workshops with a reliable and efficient solution for alloy wheel repair and maintenance. Experience the convenience and precision of this compact wheel CNC machine for enhanced productivity and customer satisfaction.

Wheel CNC Machine CK6160Q Technical Parameters

| Item | Unit | Specifications |

| Max Wheel Diameter | inch | 24″ |

| X-axis maximum stroke | mm | 320 |

| Main motor power | kw | 3 |

| Rail Width | mm | 260 |

| Wheel measuring direction | X,Z | |

| Measuring Tool | Laser or probe (optional) | |

| Measurement method | Point measurement and quick scan | |

| Program optimization | Manual and automatic | |

| Number of wheel processing programs | rows | 100000 |

| CNC System | “HAISHU” special system (touch screen operation, 17 “screen LCD display).

Universal CNC system (key operation, 10.4 “screen LCD display) (optional) |

|

| Wheel processing | Surface, rim | |

| Main drive form | Frequency control, servo drive (optional) | |

| Spindle speed | Factory setting 150~2800 | |

| Fast-moving feed | mm/min | X :5000 Z :8000 |

| Repeat accuracy | mm | X :0.01 Z :0.015 |

| Turret form | Fixed turret,Electric turret (optional) | |

| Section of turning tool | mm | 25×25 |

| Machine size(L×W×H) | mm | 1900×1400×1750 |

| Net weight | kg | 1000 |

Features of the Small Automatic Wheel Repair Lathe CK6160Q:

- Cost-effective Solution: The wheel lathe offers a simple structure, low cost, and high-performance price ratio, making it an economical choice.

- Measurement Options: Users can opt for laser scanning or probe click measurement for precise wheel data acquisition.

- Automatic Data Storage: Wheel data is automatically stored, and machining programs can be easily accessed as needed.

- Independent Software Development: The lathe features software developed in-house, allowing for automatic program optimization.

- Automatic and Efficient Processing: The machine ensures automatic, precise, and fast wheel processing.

- User-Friendly Operation: The touch screen interface enables easy operation, and the system supports multiple languages.

- Comprehensive Machining: The lathe allows for X/Z-axis measurement, wheel surface machining, and circumferential operations.

- Automatic Lubrication System: Equipped with an automatic lubrication system, the machine ensures smooth and reliable performance.

- Diamond Tool Turning: The lathe employs diamond tools for turning, resulting in smoother wheel surfaces.

- Teaching Function: The machine includes a computer-based teaching function for added convenience.

- Customizable Options: The machine can be customized according to specific customer requirements.

Mr. Kim, a reseller from South Korea, has been recommending Chinese wheel repair equipment to Korean customers while running his own auto parts company. He initially purchased our CK6180A wheel cutting lathe machine with an SYNTEC CNC system. Later, when we introduced the touch screen system, his interest was piqued, and he visited our company for inspection. On-site testing confirmed the excellent performance of our touch screen system.

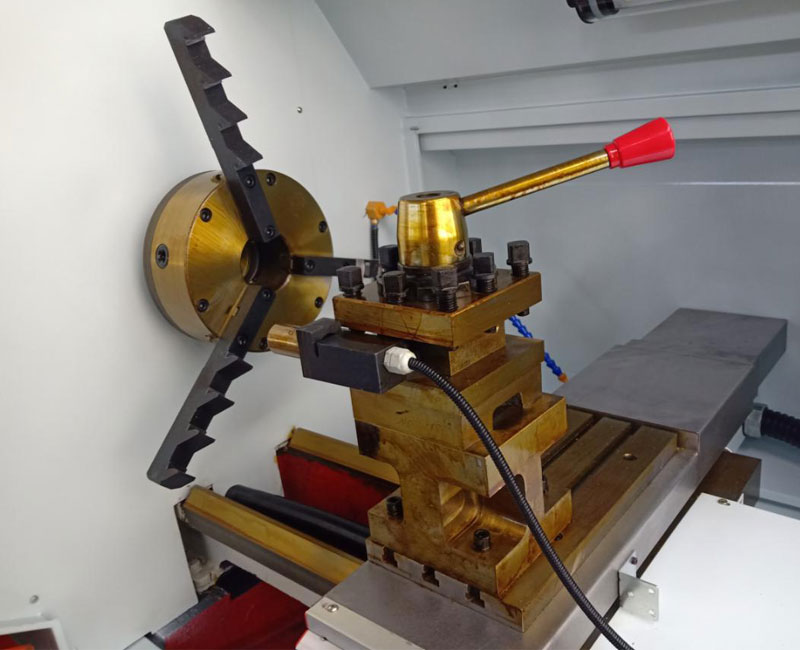

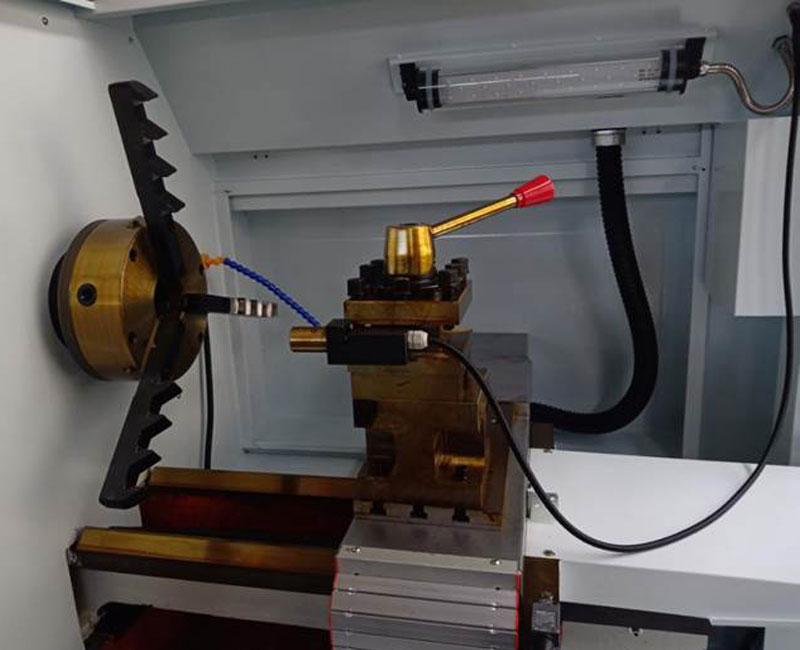

Many CK6160Q small automatic wheel polishing lathes exported to South Korea are equipped with laser detection and a gang knife. To differentiate from other customers, Mr. Kim opted for a manual four-station tool holder and a touch probe. He favored this configuration as the touch probe offers more accurate detection, particularly for complex wheel hub shapes.

It is worth noting that the touch probe operates at a slower speed compared to laser detection, as the former is point-based while the latter scans the surface. Mr. Kim is well aware of this distinction.

About HAISHU Machinery

Haishu Machinery, based in Taian, is a renowned and reputable CNC machine designer and manufacturer. With a strong commitment to providing automobile wheel production and repair solutions, we have been at the forefront of CNC lathe design and manufacturing since 2001. Our team consists of over 30 highly skilled experts, and our state-of-the-art factory spans more than 12,000 square meters.

As a global company, we are actively seeking partnerships with businesses worldwide. We believe in fostering collaborations that lead to mutual growth and success. Whether you are a distributor, reseller, or have a related industry, we welcome the opportunity to work together and provide you with our high-quality CNC machines and support services. Join us in delivering cutting-edge solutions to customers around the globe.