In today’s competitive automotive industry, having the right rim wheel repair machine is essential for any workshop or repair center. Whether you’re repairing alloy wheels, offering diamond-cut finishes, or straightening bent rims, investing in a high-quality wheel repair machine can elevate your services, improve efficiency, and boost profits.

This ultimate guide will help you understand what to look for in a rim wheel repair machine, explore various types of equipment such as wheel CNC lathes, rim straightening machines, and mobile wheel repair machines, and recommend the best options on the market, including the HAISHU Machinery CKL35 Vertical Wheel Repair Lathe.

1. Why a Rim Wheel Repair Machine is Essential for Your Workshop

A rim wheel repair machine isn’t just another piece of equipment for your workshop; it’s a long-term investment that can transform your business. By automating processes like cutting, polishing, and straightening, these machines reduce labor costs, increase repair precision, and allow you to offer premium services like diamond-cut finishes.

Key Benefits of Investing in a Wheel Repair Machine

- Increased Efficiency: Automating repairs allows technicians to complete work faster.

- Better Precision: CNC systems ensure accuracy within ±0.01 mm, delivering consistent, high-quality results.

- Expanded Services: Offer advanced options like diamond-cut finishes and crack repairs.

- Cost Savings: Reduce reliance on manual labor and minimize material waste.

- Customer Satisfaction: High-quality results mean happy clients and repeat business.

By leveraging these benefits, your workshop can stand out from competitors, attract more customers, and establish itself as a premium service provider.

2. Types of Rim Wheel Repair Machines

There are several types of wheel repair machines available, each designed for specific repair needs. Understanding the types will help you select the right one for your business.

2.1 Wheel CNC Lathe

A wheel CNC lathe is ideal for workshops that handle high-volume repairs or offer premium services like diamond-cut finishes. These machines use computer-controlled precision to restore rims and create intricate designs. CNC lathes, like the HAISHU CKL35, are reliable, durable, and user-friendly.

2.2 Rim Straightening Machine

For workshops focusing on bent or damaged rims, a rim straightening machine is essential. These machines apply hydraulic or mechanical force to reshape rims back to their original form, ensuring they are safe for road use.

2.3 Vertical Wheel Repair Lathe

A vertical wheel repair lathe is perfect for repairing larger wheels, such as those used on SUVs and trucks. Its vertical design ensures stability and accuracy during repairs, making it an excellent choice for workshops that handle diverse vehicle types.

2.4 Mobile Wheel Repair Machine

A mobile wheel repair machine is a portable solution for workshops that want to offer on-site repairs or cater to customers who prefer convenience. These machines are compact yet versatile, allowing technicians to perform high-quality repairs remotely.

2.5 Comprehensive Wheel Repair Equipment

Some machines combine multiple functions, such as straightening, CNC cutting, and polishing, into one versatile piece of equipment. These are ideal for workshops looking to maximize their capabilities and cater to a broader range of customer needs.

3. How to Choose the Best Rim Wheel Repair Machine

When selecting a rim repair machine, it’s crucial to consider your workshop’s needs, budget, and the type of repairs you plan to offer. Here are some key factors to evaluate:

3.1 Compatibility with Wheel Sizes

The machine should accommodate a wide range of wheel sizes. For example, the HAISHU CKL35 Vertical Wheel Repair Lathe handles wheels from 14 to 35 inches, making it suitable for most vehicles, including sedans, SUVs, and luxury cars.

3.2 Precision and Accuracy

Precision is key to delivering high-quality repairs. Look for machines with a tolerance level of at least ±0.01 mm. CNC systems are especially effective for achieving consistent results and satisfying demanding customers.

3.3 Automation Features

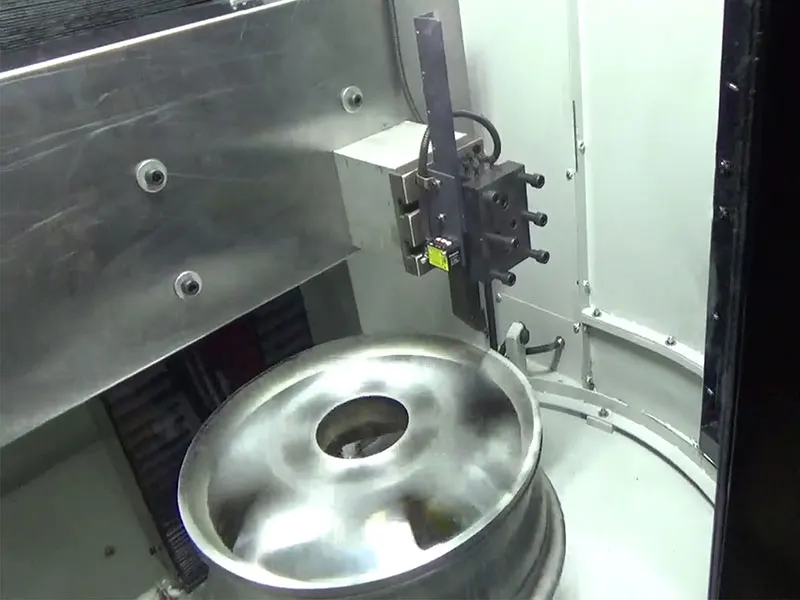

Advanced automation, like laser scanning and pre-programmed templates, reduces human error and speeds up repairs. Machines like the HAISHU CKL35 include fully automated systems for cutting, polishing, and straightening, ensuring efficiency and accuracy.

3.4 Durability and Build Quality

Invest in machines made of durable materials like industrial-grade cast iron. This ensures long-term reliability even with heavy use, reducing the need for frequent repairs and replacements.

3.5 Ease of Use

Choose a machine with an intuitive interface, such as a touchscreen control panel. This minimizes the learning curve and ensures that even less experienced technicians can operate it efficiently.

3.6 After-Sales Support

A reliable manufacturer should offer training, technical support, and easy access to replacement parts. HAISHU Machinery is renowned for its excellent customer service, including comprehensive training programs to ensure your team gets the most out of their equipment.

4. Why HAISHU Machinery is the Best Choice

When it comes to finding the best wheel repair equipment, HAISHU Machinery stands out as a trusted name in the industry. With years of experience and thousands of satisfied customers worldwide, HAISHU offers cutting-edge technology and reliable products.

4.1 Top Reasons to Choose HAISHU Machinery

- High-Quality Equipment: Machines like the CKL35 Vertical Wheel Repair Lathe are built to last and deliver exceptional performance.

- Advanced Technology: HAISHU machines feature state-of-the-art CNC systems for precise and automated repairs.

- Comprehensive Support: From installation to maintenance, HAISHU provides end-to-end support to ensure your success.

- Wide Range of Products: Whether you need a rim straightening machine, wheel CNC lathe, or mobile wheel repair machine, HAISHU has you covered.

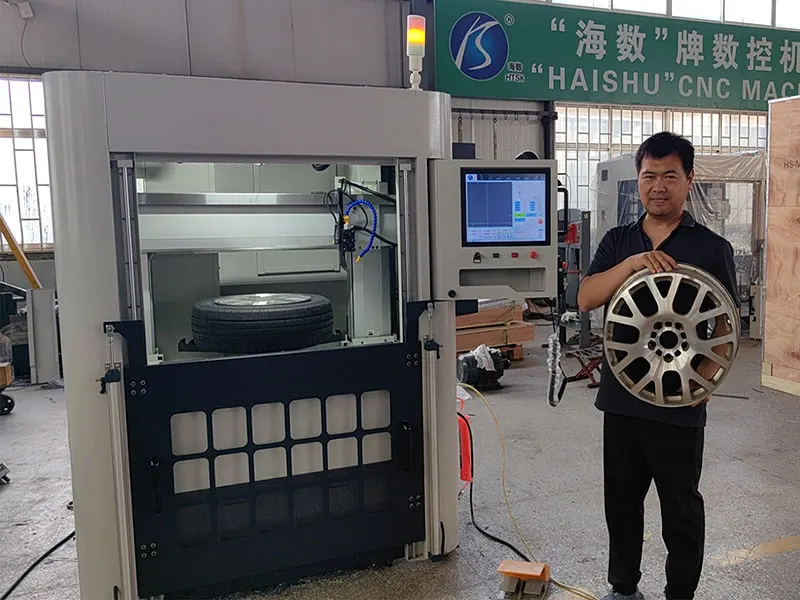

5. Introducing the HAISHU CKL35 Vertical Wheel Repair Lathe

The HAISHU CKL35 is a top-tier vertical wheel repair lathe designed for workshops that demand versatility, precision, and efficiency. Here’s why it’s a game-changer:

5.1 Key Features of the HAISHU CKL35

- Wheel Size Range: Repairs wheels from 14 to 35 inches, making it suitable for most vehicles.

- High Precision: CNC technology ensures accuracy within ±0.01 mm.

- Automation: Fully automated cutting, polishing, and straightening processes reduce labor and improve efficiency.

- Durable Construction: Built with industrial-grade cast iron for maximum stability and longevity.

- User-Friendly Interface: A touchscreen control panel simplifies operation, even for beginners.

5.2 Ideal Applications

The HAISHU CKL35 is perfect for:

- Workshops handling high volumes of wheel repairs.

- Businesses offering premium services like diamond-cut finishes.

- Repair centers that cater to luxury vehicles with larger wheels.

6. Tips for Maximizing the ROI of Your Wheel Repair Equipment

Investing in a rim repair machine is only part of the equation; using it effectively is equally important. Here are some tips to get the most out of your equipment:

- Train Your Team: Ensure that all technicians are properly trained to operate the machine.

- Regular Maintenance: Schedule routine maintenance to keep your equipment in top condition.

- Offer Premium Services: Use features like diamond-cut finishes to attract high-end clients.

- Promote Your Services: Market your new capabilities to existing and potential customers.

- Monitor Performance: Track repair times and customer feedback to continuously improve.

7. Conclusion: Invest in the Best Rim Wheel Repair Machine Today

Choosing the right rim wheel repair machine is crucial for the success of your workshop. By investing in high-quality equipment like the HAISHU CKL35 Vertical Wheel Repair Lathe, you can deliver exceptional results, expand your services, and grow your business.

Whether you need a wheel CNC lathe, a rim straightening machine, or a mobile wheel repair machine, HAISHU Machinery offers reliable solutions tailored to your needs. Their advanced technology, durable construction, and excellent customer support make them the ideal choice for any professional workshop.

Ready to take your business to the next level? Visit HAISHU Machinery today and discover how their innovative wheel repair equipment can transform your operations.