1. What are CNC Alloy Wheels?

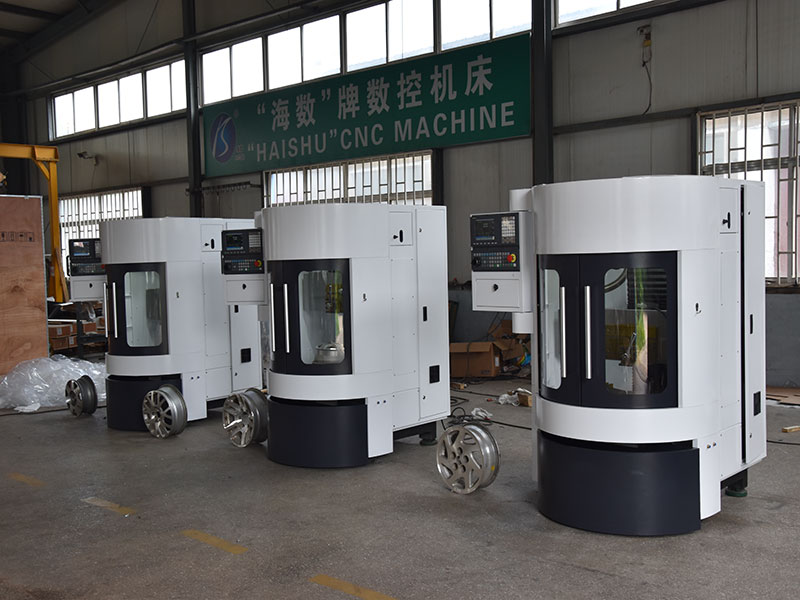

CNC alloy wheels refer to refurbishing and repairing alloy automotive wheels using specialized CNC lathe machines designed for wheel repair. When selecting an alloy wheel repair machine, many buyers are often unsure about the available configurations and functionalities. To clarify, we will introduce Taian Haishu, a leading manufacturer of CNC alloy wheels, and their innovative wheel repair machines.

2. What Are the Key Features of CNC Alloy Wheels?

2.1 Understanding the CNC System

The core of CNC alloy wheels is the CNC system itself. Current CNC systems can be divided into two main categories: traditional CNC lathe systems and specialized wheel repair systems.

2.2 Traditional CNC Lathe Systems

Traditional CNC lathe systems are complex and require a high level of technical skill from operators. This complexity often increases labor costs, making them less appealing for businesses focused on wheel repairs.

2.3 Specialized Wheel Repair Systems

In contrast, specialized wheel repair systems are designed specifically for automotive wheel refurbishment. These systems offer greater versatility and are tailored to meet the specific needs of alloy wheel repairs. Taian Haishu has developed a unique CNC wheel repair system that emphasizes ease of use and efficiency.

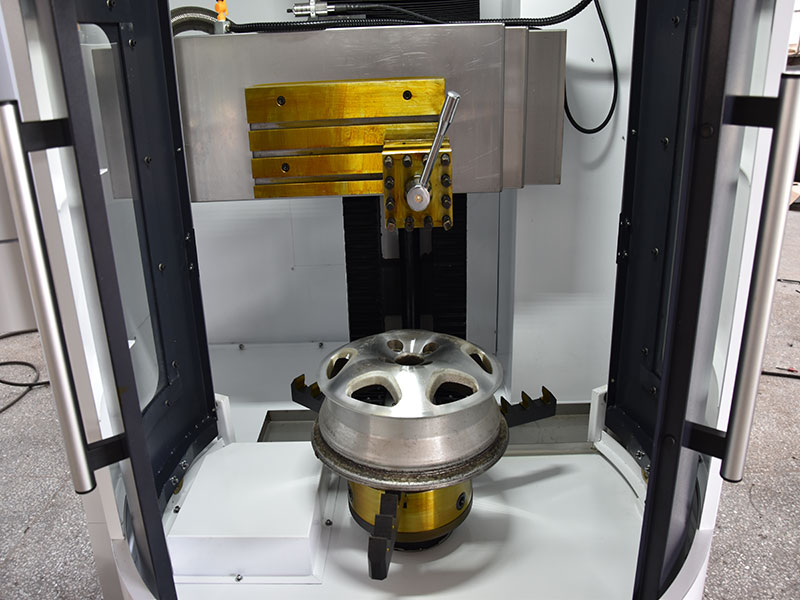

3. How Does Detection Work in CNC Alloy Wheels?

3.1 Types of Detection Methods

When it comes to detecting issues with alloy wheels, other manufacturers typically offer only one detection method, such as laser or probe detection. However, Taian Haishu stands out by providing three different detection systems.

3.2 Laser Detection

Laser detection is the most popular method among customers and can be completed in just 15 seconds. This rapid process allows for quick assessments, making it ideal for busy workshops.

3.3 Probe Detection

Probe detection, while effective, takes longer—about 10 minutes—and poses risks of bending or collisions when dealing with significantly curved wheel surfaces.

3.4 Tip Detection

The third option is tip detection, which applies to nearly all wheel surfaces. Although it is the most precise, it is also the most time-consuming. By offering these three detection methods, Taian Haishu positions itself as a leader in the wheel refurbishment machine industry.

4. What Is Curve Optimization in CNC Alloy Wheels?

4.1 Importance of Curve Optimization

After completing the detection process, curve optimization becomes essential. This step tests the technicians’ skills and is crucial for achieving the desired refurbishment results.

4.2 Automatic and Manual Optimization

To simplify this complex process, Taian Haishu offers both automatic and manual optimization methods.

- Automatic Optimization: After detection, the system automatically enhances the wheel surface curves.

- Manual Optimization: For those who prefer a hands-on approach, technicians can manually select points on the curve surface to customize the refurbishment effect.

This flexibility allows for a tailored approach to wheel surface optimization.

5. How Does CNC Programming Work in CNC Alloy Wheels?

5.1 Streamlined CNC Programming

Once the curve optimization is complete, the next step is CNC programming. Traditional programming often requires extensive skill and can be time-consuming, leading to inefficiencies and potential errors.

5.2 One-Click Program Output

Taian Haishu has developed a one-click program output feature that allows for CNC program generation in just one second. This process minimizes programming errors and enables even beginners to perform advanced CNC programming effectively.

6. What Are the Tool Setting Requirements for CNC Alloy Wheels?

6.1 Importance of Precise Tool Setting

After CNC programming, precise tool setting is crucial for successful machining. However, achieving this requires high skill levels from personnel, which can raise labor costs.

6.2 One-Click Tool Setting Feature

To address this challenge, Taian Haishu’s wheel CNC machine includes a one-click tool setting feature. This innovation resets the X and Z axis starting points for machining, significantly simplifying the operation. As a result, even newcomers can effectively perform advanced CNC operations without extensive training.

7. Why Choose Taian Haishu for CNC Alloy Wheels?

7.1 Commitment to Quality and Service

If you’re considering purchasing a wheel repair lathe or aluminum wheel CNC lathe, Taian Haishu should be your top choice. Our substantial financial resources, physical factories, and systematic after-sales service make us a reliable partner for your business needs.

7.2 Global Reach and ODM Options

With sales and regional distributors in over 90 countries, we ensure worry-free purchasing and after-sales support. Additionally, we offer ODM production models, allowing you to brand your own wheel repair machine, and enhancing your market presence.

7.3 Conclusion

In summary, understanding CNC alloy wheels and the functionalities of a CNC alloy wheel repair machine is essential for making an informed purchasing decision. By focusing on detection methods, curve optimization, CNC programming, and tool setting, you can choose a machine that meets your specific needs.

If you are ready to invest in a quality wheel repair machine, don’t hesitate to contact us by phone or email. Our professional team at Taian Haishu is dedicated to serving you with the utmost sincerity and expertise.