1. What Constitutes an Appropriate CNC Wheel Machine Price?

When selecting a CNC wheel machine, determining an appropriate price can be a complex issue. Various factors influence the price, including configuration, operation, quality, after-sales service, and ease of use. This article will explore what makes a CNC wheel machine price suitable for customers, using Taian Haishu Company’s wheel refurbishing lathe as a reliable reference.

2. How Does the Structure Affect CNC Wheel Machine Price?

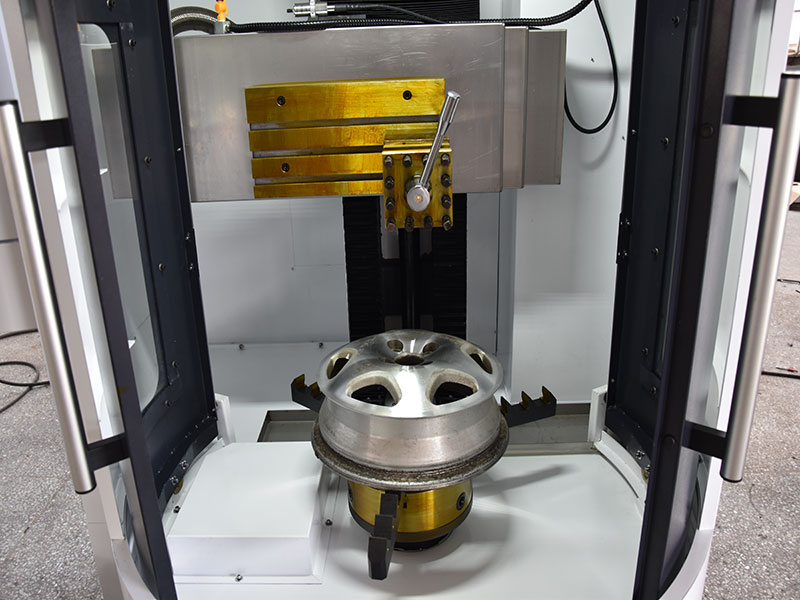

2.1 Horizontal vs. Vertical Structures

One of the primary structural considerations influencing the CNC wheel machine price is whether the machine is horizontal or vertical. In this context, “horizontal” and “vertical” refer to the Z-axis orientation of the machine tool.

- Horizontal Wheel Refurbishing Lathe: The Z-axis is parallel to the ground. Generally, these machines are less expensive than vertical models.

- Vertical Wheel Refurbishing Lathe: The Z-axis is perpendicular to the ground, allowing wheels to be placed flat on the fixture. This design offsets some centrifugal forces and provides better rigid support for larger wheels.

In general, a vertical wheel refurbishing lathe tends to have a higher price tag. If the budget allows, opting for a vertical structure is advisable for enhanced performance.

3. What Role Does the Wheel Refurbishing System Play in Pricing?

3.1 Importance of the Control System

The wheel refurbishing system serves as the brain of the CNC wheel machine. Its comprehensiveness and ease of operation are critical in determining the overall price.

- Taian Haishu’s System Features:

- Laser Detection: Enhances accuracy in repairs.

- Automatic Optimization: Allows for quick adjustments.

- One-Button Tool Setting: Simplifies the setup process.

- Real-Time Coordinate Modification: Provides flexibility during operation.

Additionally, this system supports probe detection and tooltip detection, increasing the storage capacity for wheel programs. Custom naming of programs for easy recall is another practical feature. These upgrades are designed to help customers quickly complete wheel surface repairs, adding significant value to the machine.

4. How Do Guideways Impact CNC Wheel Machine Price?

4.1 Linear vs. Hard Guideways

The type of guideways used in a CNC wheel machine significantly influences the price and performance.

- Linear Guideways: Ideal for wheel refurbishing machines, particularly for aluminum alloy wheels, due to their high smoothness and precision. They allow for rapid movement and can be easily replaced if damaged, maintaining the machine’s original precision.

- Hard Guideways: Although cheaper, hard guideways cannot achieve the same rapid movement and are less effective after wear and tear. Choosing hard guideways might save costs upfront but could lead to reduced accuracy over time.

For customers with a sufficient budget, linear guideways are the preferred choice for maintaining high-quality performance in wheel CNC machines.

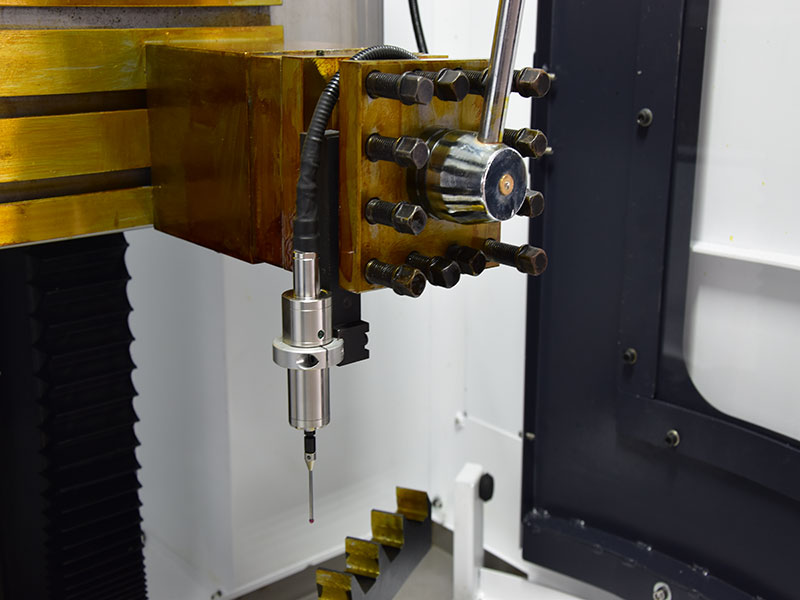

5. Which Tool Holder Options Should You Consider for CNC Wheel Machines?

5.1 Evaluating Tool Holder Types

The tool holder is another essential component influencing the CNC wheel machine price. Different types of tool holders offer varying benefits and costs.

- Straight Row Tool Holder:

- Most cost-effective option.

- Does not require tool changing, allowing for the direct installation of tools and probes.

- Low maintenance and replacement costs.

- Manual Tool Holder:

- Requires manual tool changes, leading to potential wire tangling issues.

- Moderate cost but may complicate operations.

- Electric Four-Station Tool Holder:

- Automatically changes tools, minimizing tangling problems.

- Higher initial costs and repair difficulty if damaged later.

Selecting the right tool holder is crucial for optimizing the performance of your wheel repair lathe.

6. What Are the Additional Features to Consider in CNC Wheel Machine Pricing?

6.1 Functional Configurations

When assessing the CNC wheel machine price, additional features and configurations should also be considered.

- Customization Options: Taian Haishu offers custom services to meet specific client requirements, including voltage, tools, and configurations.

- After-Sales Service: Reliable after-sales support is essential for maintaining machine performance and longevity.

- Ease of Use: Machines that are user-friendly can reduce training time and increase productivity.

These factors contribute to the overall value of the wheel repair machine.

7. How to Navigate the Pricing of CNC Wheel Machines?

7.1 Key Considerations for Customers

When determining the appropriate CNC wheel machine price, customers should consider the following:

- Initial Investment vs. Long-Term Value: While some machines may have a lower initial cost, their long-term reliability and performance should be evaluated.

- Return on Investment (ROI): Analyze how quickly the machine can pay for itself through increased efficiency and reduced labor costs.

- Customization Needs: Identify whether the machine can be tailored to your specific operational requirements.

By carefully weighing these considerations, customers can make informed decisions when purchasing a wheel CNC machine.

8. Conclusion

In summary, understanding the various factors that influence the CNC wheel machine price is crucial for making an informed purchasing decision. Taian Haishu’s comprehensive offerings, from the structural design to advanced features, provide excellent options for those seeking high-quality aluminum wheel CNC lathes and CNC alloy wheel repair machines.

If you wish to learn more about our wheel refurbishing machines and how they can enhance your operations, don’t hesitate to get in touch with us. We invite you to visit our factory to explore our products firsthand and discover how we can meet your specific needs. Investing in a reliable wheel repair machine will significantly improve your production capabilities.