What is a Car Rim Repair Machine?

A car rim repair machine is a specialized CNC (Computer Numerical Control) lathe designed to repair damaged alloy wheels. Damages such as bends, cracks, scratches, or surface dents caused by potholes, curb hits, or accidents can affect the performance and appearance of a vehicle. Replacing damaged rims can be costly, but a car rim repair machine restores them to their original condition in a cost-effective and efficient manner.

These machines are designed to handle tasks such as:

- Straightening bent rims.

- Polishing and refinishing scratched surfaces.

- Restoring the structural integrity of damaged rims.

Modern car rim repair machines come equipped with advanced CNC systems, user-friendly interfaces, and high-precision tools to deliver factory-quality results. With the growing demand for alloy wheel repair services, these machines have become a necessity for workshops in Turkey and globally.

What Are the Advantages of a Car Rim Repair Machine?

Investing in a car rim repair machine offers several benefits for automotive repair workshops:

1. Cost-Effective Repairs

Instead of replacing damaged rims, workshops can repair them at a fraction of the cost. This provides a more affordable solution for customers while increasing profit margins for the business.

2. High Precision and Efficiency

With CNC technology, car rim repair machines can achieve high levels of accuracy, ensuring that repaired rims meet original specifications. Features like one-click optimization and program output make the repair process faster and easier.

3. Versatility

Car rim repair machines can handle various types of wheel damage, including bends, cracks, and surface scratches. Some machines are capable of repairing rims up to 35 inches in diameter, making them suitable for a wide range of vehicles.

4. Improved Customer Satisfaction

By offering quick and high-quality repairs, workshops can build trust and satisfaction among their customers, which enhances their reputation and increases repeat business.

5. Environmentally Friendly

Repairing rims instead of replacing them reduces waste, making the process more sustainable and eco-friendly.

What Are the Configurations of a Car Rim Repair Machine?

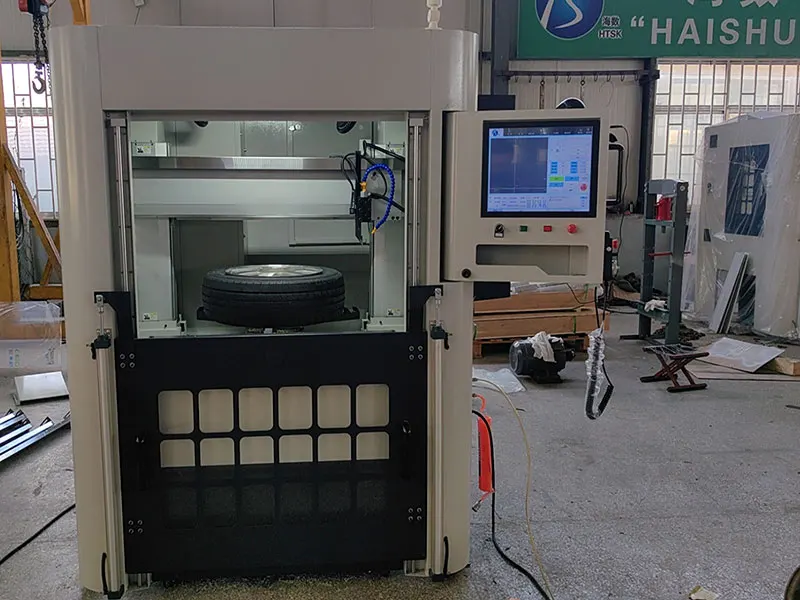

The performance of a car rim repair machine largely depends on its configurations. Taian Haishu Machinery is a leader in manufacturing these machines and offers a variety of models equipped with advanced features to meet the diverse needs of automotive workshops. Here are some key configurations:

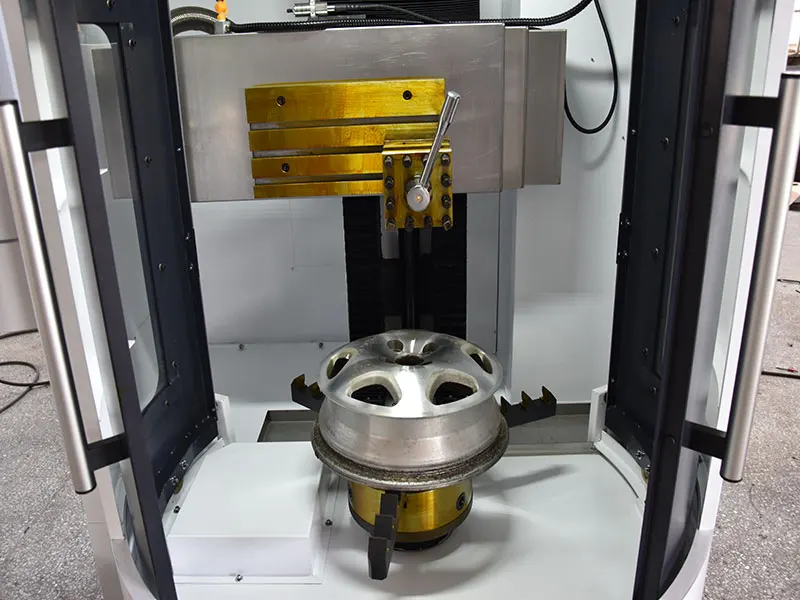

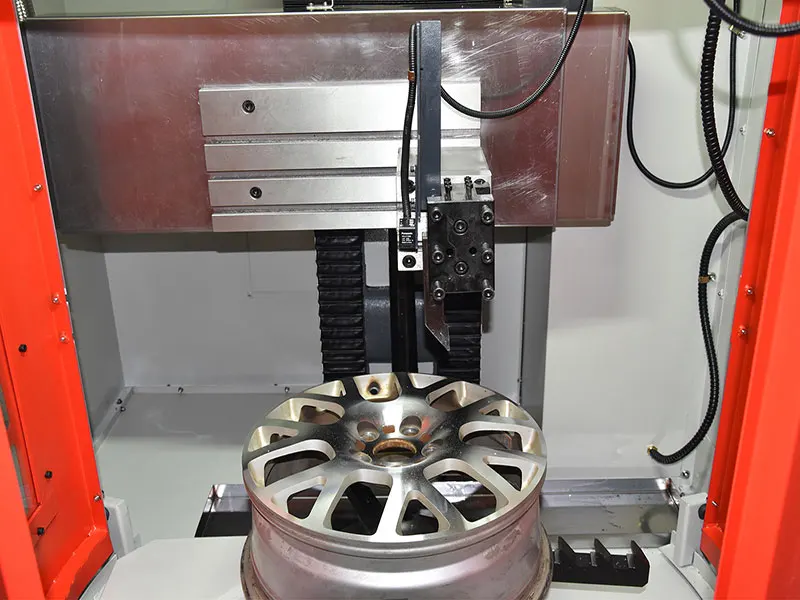

1. Horizontal and Vertical Hub Repair Lathes

Car rim repair machines are often classified into two types based on the spindle installation:

- Horizontal Hub Repair Machines: These have the spindle installed horizontally and are ideal for repairing rims up to 22 inches.

- Vertical Hub Repair Machines: These have the spindle installed vertically, making them suitable for larger rims (26–35 inches). Vertical machines are more stable and can handle the effects of gravity and centrifugal force more effectively.

2. CNC System with One-Click Operations

Taian Haishu’s machines are equipped with advanced CNC systems, featuring a 17-inch touch screen. Functions like one-click path optimization, one-click tool setting, and one-click program output enhance usability and efficiency.

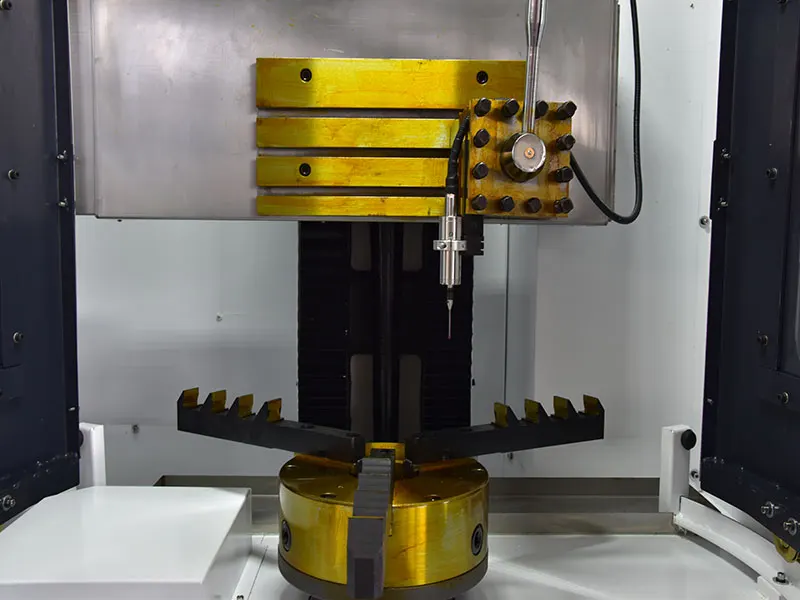

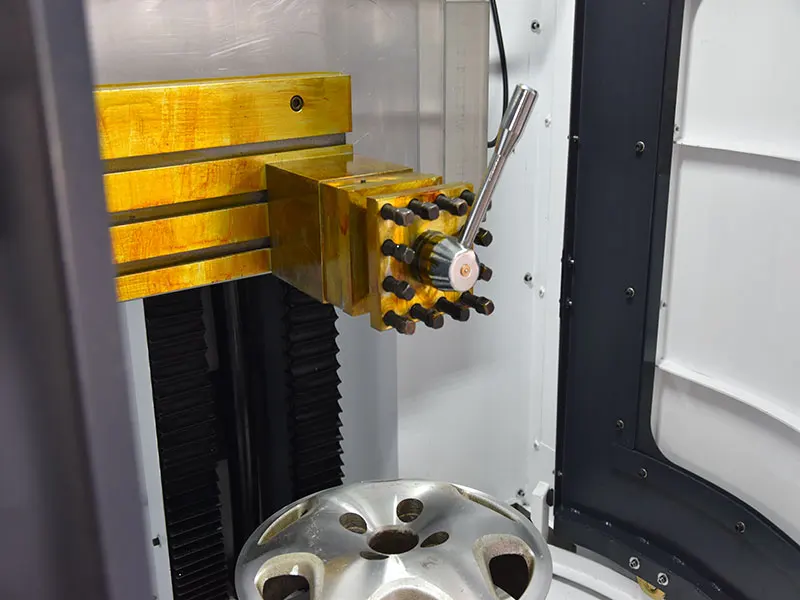

3. Flexible Chuck Options

Machines come with three-jaw or four-jaw self-centering chucks, ensuring secure and precise clamping of rims for repair.

4. Linear Guide Configurations

Linear guides improve processing speed and accuracy, particularly in vertical machines.

5. Visual Monitoring

Many machines include video monitoring systems, allowing operators to oversee the repair process in real-time for better control and precision.

Example: CKL22Q Model by Taian Haishu Machinery

The CKL22Q car rim repair machine is one of the most popular models in Taian Haishu’s lineup. Known for its durability, precision, and user-friendly features, the CKL22Q stands out as an excellent option for workshops in Turkey.

Key Features of CKL22Q:

- Rim Size Compatibility: Handles rims up to 26 inches in diameter.

- CNC System: Equipped with a 17-inch touch screen and one-click functions for easy operation.

- Tool Holder: Straight-row or four-station tool holders for added flexibility.

- Linear Guide Rails: Ensures high precision and fast movement during repairs.

- Certifications: CE-certified for safety and ISO 9000-certified for quality assurance.

With its compact design, advanced features, and affordable price, the CKL22Q is ideal for workshops looking to expand their services.

How to Choose a Suitable Car Rim Repair Machine?

Choosing the right car rim repair machine is critical for ensuring your workshop’s success. Here are some factors to consider:

1. Rim Size Compatibility

Evaluate the range of rim sizes your workshop typically handles. Horizontal machines are suitable for smaller rims, while vertical machines can accommodate larger rims up to 35 inches.

2. Machine Structure

Choose between horizontal and vertical hub repair machines based on your specific repair needs and budget. Vertical machines are more versatile, but horizontal machines are a cost-effective choice for smaller rims.

3. Technical Features

Look for features like one-click operations, visual monitoring, and advanced CNC systems to improve efficiency and precision.

4. Manufacturer Reputation

Buy from a reputable manufacturer like Taian Haishu Machinery, which offers high-quality machines, customization options, and reliable after-sales support.

5. Certifications

Ensure the machine has certifications like CE for safety and ISO 9000 for quality.

Why Choose Taian Haishu Machinery?

Taian Haishu Machinery is a global leader in manufacturing car rim repair machines, with over 23 years of experience in the industry. Here’s why they are a trusted choice for workshops in Turkey and around the world:

1. Comprehensive Solutions

Taian Haishu offers a wide range of machines, including wheel repair machines, wheel CNC machines, and brake drum repair lathes.

2. Customizability

Machines can be customized in any language, working voltage, and configuration to meet specific customer needs.

3. Global Certifications

The company is ISO 9000-certified and CE-certified, ensuring high-quality and safe products.

4. Patented Technology

Taian Haishu holds patents in regions like South Korea and the European Union, showcasing their commitment to innovation.

5. Reliable Support

With 7×24-hour customer service and the option for onsite factory visits, Taian Haishu provides complete peace of mind for its customers.

Conclusion

A car rim repair machine is an essential tool for automotive workshops, providing a cost-effective, precise, and environmentally friendly solution for repairing damaged alloy wheels. Whether you’re dealing with small passenger car rims or larger SUV rims, these machines can handle a variety of repair tasks with ease.

When choosing a car rim repair machine, consider factors like rim size compatibility, machine structure, technical features, and manufacturer reputation. Taian Haishu Machinery stands out as a trusted supplier, offering high-quality machines like the CKL22Q, backed by decades of experience and global certifications.

For workshops in Turkey looking to enhance their services, investing in a reliable car rim repair machine from Taian Haishu is a smart and profitable decision. Contact them today to find the perfect solution for your business needs.