1. What is a CNC Machine for Alloy Wheels?

A CNC machine for alloy wheels is a specialized piece of equipment designed to repair damaged and deformed alloy wheels. These machines play a critical role in maintaining the aesthetic and functional value of vehicles. Primarily focused on alloy wheels, they cater to a variety of designs, including sporty and luxury brand wheels. Given the high cost of luxury wheels, refurbishing them through a CNC process is often more economical than replacement. The growing modified wheel industry also relies on these wheel repair machines (Rad reparatur maschine), which have become increasingly prevalent in the automotive market.

2. Why Invest in a CNC Machine for Alloy Wheels?

2.1 The Value of Wheel Repair Lathes

Investing in a wheel repair lathe (máquina de reparación de ruedas) allows automotive businesses to offer refurbishment services that can significantly enhance profit margins. With the ability to restore wheels to their original condition, shops can attract customers who are looking to save money on expensive replacements.

2.2 Market Demand and Opportunities

The demand for wheel repair machines (macchina per la riparazione di ruote) is growing as consumers become more aware of the benefits of wheel refurbishment. This trend is particularly strong in the luxury vehicle segment, where the costs associated with new wheels can be prohibitive. By acquiring a CNC machine for alloy wheels, businesses can penetrate this lucrative market and meet the needs of discerning customers.

3. How Do CNC Machines for Alloy Wheels Work?

3.1 Design and Construction of Wheel CNC Machines

The bed of a wheel CNC machine (машина для ремонта колес) is typically constructed from high-strength cast iron, which provides excellent rigidity and stability. This design allows the machine to withstand cutting forces and vibrations during the machining process, ensuring consistent processing accuracy. However, long-term use can wear down cast iron guide rails, affecting precision.

3.2 Advanced Guide Rail Technology

To combat wear and maintain accuracy, manufacturers like Taian Haishu incorporate linear guide rails in their aluminum wheel CNC lathe (máy sửa chữa bánh xe) designs. These guide rails not only offer faster movement but also deliver high processing accuracy suitable for the smoothness required for aluminum alloy wheels. If damaged, linear guide rails can be easily replaced, allowing the machine to restore accuracy quickly and economically.

4. Key Features of a CNC Machine for Alloy Wheels

4.1 Feed System Technology

The feed system is a core component of any diamond cut wheel lathe. Taian Haishu employs a servo motor as the feed motor, which facilitates backlash compensation and allows for real-time monitoring of processing data. This results in high processing accuracy and precise transmission. The combination of servo motors and ball screw transmission enhances overall efficiency and stability in the wheel repair process.

4.2 Wheel Repair System Functionality

The wheel repair system acts as the “brain” of a wheel repair machine (máquina de reparação de rodas). Taian Haishu’s innovative system includes features such as automatic detection, optimization of CNC programs, and one-click tool settings. These functionalities streamline the repair process significantly.

4.3 Detection Methods

- Laser Detection: This method is the fastest, taking only 15 seconds, making it ideal for smooth wheel surfaces.

- Probe Detection: More comprehensive, this method takes 5-8 minutes and is best for wheels with substantial undulations.

- Tool Tip Detection: The most precise but time-consuming option, suitable for wheels with extreme deformations.

Having these three detection methods available is a unique feature of Taian Haishu’s machines, making them stand out in the market.

5. What Makes Taian Haishu’s CNC Machine for Alloy Wheels Unique?

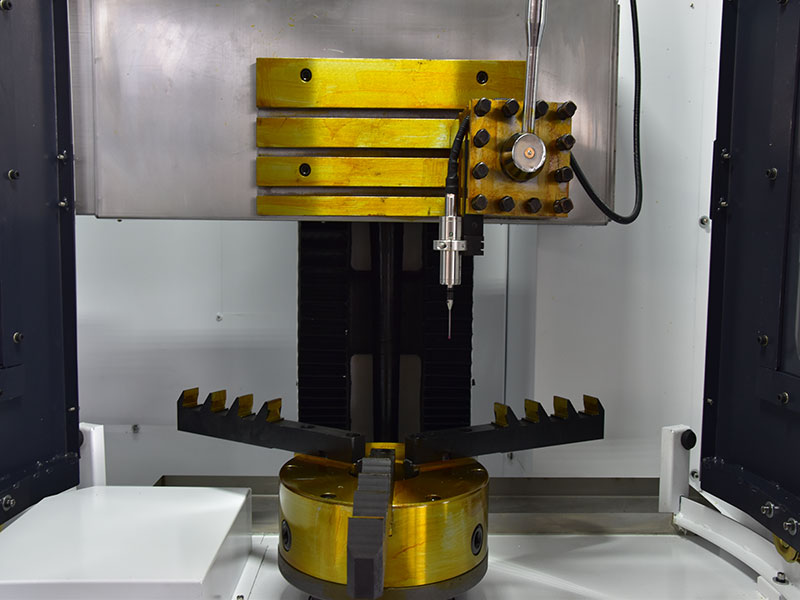

5.1 Innovative Wheel Fixture Design

The wheel repair machine (휠 수리 기계 (휠 수리 기계)) features two distinct clamping methods:

- Center Positioning Method: This involves a threaded flower disk and tapered positioning block to secure the wheel accurately.

- Three-Jaw Chuck Method: Customized jaws are precisely cut to allow for quick and stable clamping, ensuring reliable performance during repair.

5.2 Benefits of Versatile Clamping Techniques

The ability to switch between these clamping methods enhances the versatility of the CNC machine for alloy wheels, accommodating various wheel types and sizes. This adaptability is crucial for any business aiming to provide comprehensive wheel repair services.

6. How to Choose the Right CNC Machine for Alloy Wheels

6.1 Criteria for Selection

When selecting a wheel CNC machine (آلة إصلاح العجلات), consider factors such as build quality, technological features, and after-sales support. A robust machine with high-strength materials will offer better longevity and performance.

6.2 Importance of After-Sales Support

Choosing a manufacturer that provides reliable after-sales support is crucial. Taian Haishu not only offers high-quality wheel repair lathes (machine de réparation de roues) but also ensures customers receive ongoing support, including lifetime upgrades for their systems.

7. Customization and OEM Services

7.1 Tailored Solutions for Businesses

Taian Haishu also provides ODM and OEM services for businesses that wish to customize machine functionalities or brand them under their own name. This flexibility allows businesses to meet specific market demands and customer preferences.

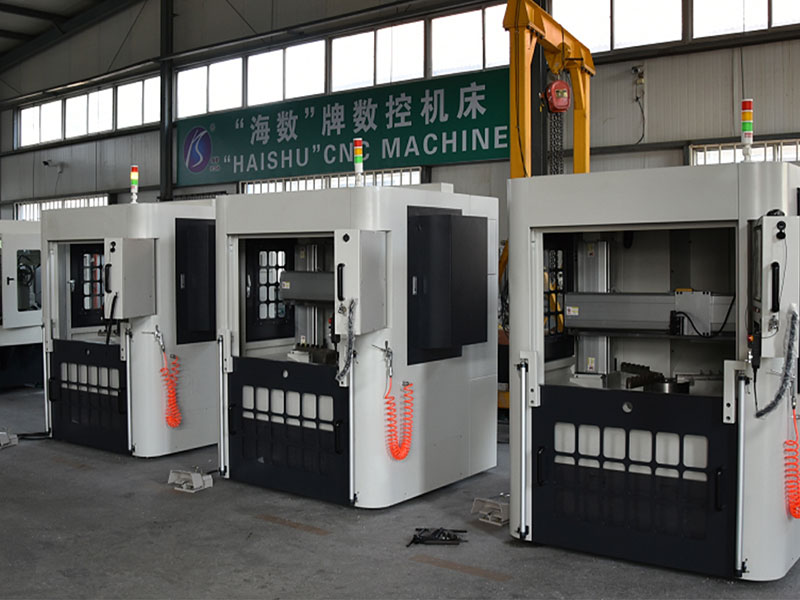

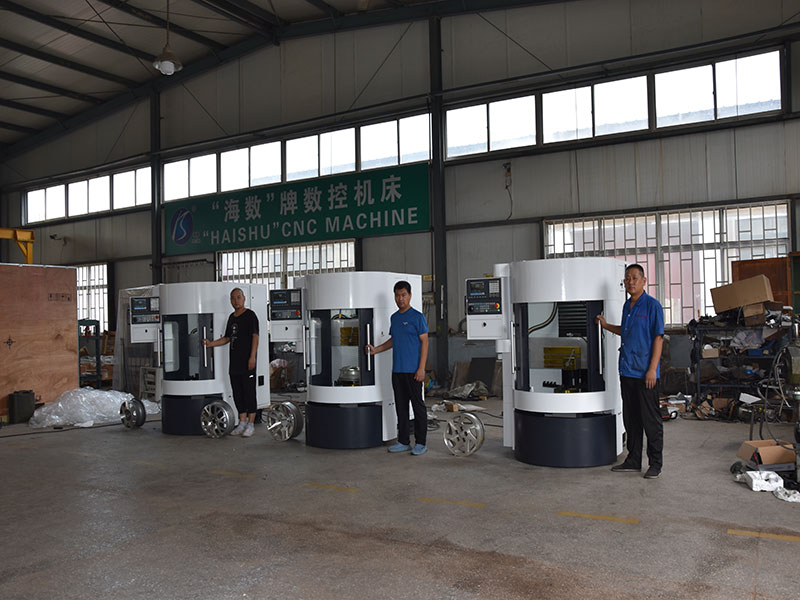

7.2 Visiting the Manufacturer

Potential buyers are encouraged to visit the Taian Haishu factory. This opportunity allows customers to see the machines in action and gain a better understanding of their capabilities. Professional consultations can guide businesses in selecting the right equipment for their unique needs.

8. Conclusion: The Future of Wheel Repair with CNC Machines

Investing in a CNC machine for alloy wheels is a strategic move for any automotive business looking to excel in the wheel repair industry. With advanced features, robust construction, and unique clamping methods, machines like those from Taian Haishu set the standard for quality and efficiency. As the market for wheel refurbishment continues to expand, having the right equipment will ensure your business remains competitive and capable of delivering exceptional results.

By leveraging the latest technology and understanding the specific needs of customers, businesses can maximize their potential in the automotive wheel shaping industry. Whether focusing on repairing sporty wheels or luxury brand options, the right wheel repair machine (wielen reparatiemachine) will enhance operations and provide significant returns on investment.