1. What is a Rim Bending Machine?

1.1 Definition and Purpose

A rim bending machine, also known as a wheel hub straightening or correcting machine, is a specialized lathe equipped with turning capabilities. It is specifically designed to reshape deformed wheel rims, making it an essential tool in the automotive repair industry. These machines are crucial for restoring the structural integrity and performance of wheels that have been damaged due to accidents or road hazards.

1.2 Importance of Rim Bending Machines

The significance of a wheel repair lathe lies in its ability to repair rather than replace damaged wheel hubs. This not only saves money but also reduces waste, making it an economical and environmentally friendly solution. By using a wheel CNC machine, technicians can ensure that wheels are safe and balanced for optimal driving performance.

2. How Does a Rim Bending Machine Work?

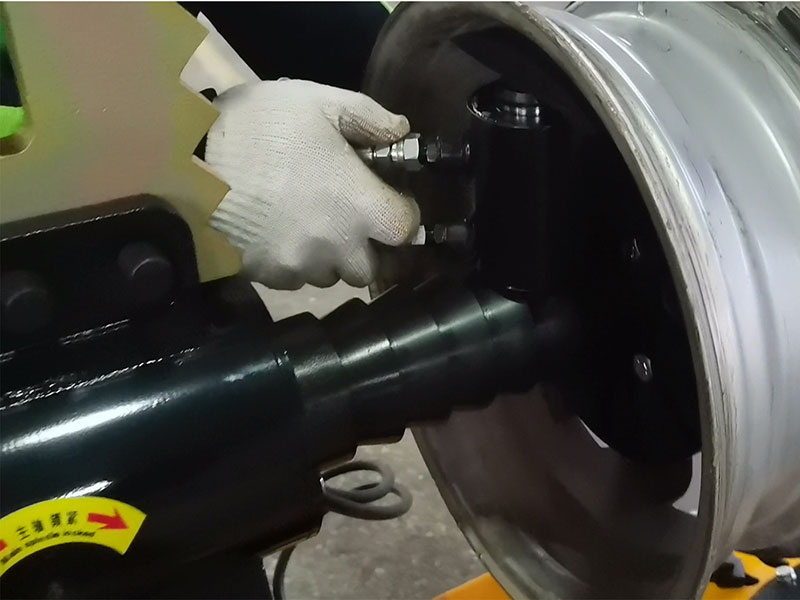

2.1 Initial Steps in the Rim Repair Process

The process begins with the removal of the tire from the wheel using a tire changer. Once the tire is off, the wheel hub is mounted on the rim bending machine. This machine features a specialized chuck that can securely hold the wheel hub, accommodating 99% of wheel hub installations on the market.

2.2 Inspection for Damage

Technicians manually rotate the wheel hub to inspect for cracks or other damage. If cracks are detected, they require preheating using a fire-baking method before applying specialized aluminum welding techniques. This step is crucial, as it requires skilled craftsmanship to prevent re-cracking and ensure the safety of the repaired wheel.

3. What Are the Benefits of Using a Rim Bending Machine?

3.1 Cost-Effectiveness

One of the primary advantages of using a rim bending machine is the cost savings associated with wheel repair. Replacing a deformed or cracked wheel hub can be expensive, while repairing it with a rim bending machine is significantly more economical. This makes it an attractive option for both individual vehicle owners and automotive repair shops.

3.2 Safety Considerations

Using a rim bending machine also enhances safety. Deformed wheels can lead to imbalances while driving, potentially endangering the driver and passengers. By repairing the wheel hub properly, technicians can restore balance and improve overall vehicle safety.

4. What are the steps involved in using a rim-bending machine?

4.1 Welding and Finishing

After identifying and addressing any cracks, the wheel hub is briefly cleaned. The welded areas are then cut using specialized cutting tools that follow the original edge curvature of the wheel hub. This process is essential to prevent air leakage when inflating the tire. Polishing paper is used for finishing, followed by surface polishing in a polishing tank.

4.2 Painting and Balancing

Once the surface is polished, clear paint is sprayed onto the wheel hub using painting equipment and dried in an oven. After drying, the hub is balanced on a wheel balancing machine to ensure it meets safety standards before being installed back on the vehicle.

5. How is a Rim Bending Machine Used for Deformed Wheels?

5.1 Identifying Deformation

If the wheel hub is not cracked but deformed, a different approach is required. The hub is mounted on the chuck, and long correction pins are used to identify the dented areas, which are then marked for correction.

5.2 Reshaping Process

A heating device is used to soften the deformed areas, followed by reshaping using a hydraulic jack equipped with multiple heads. This hydraulic system, often sourced from manufacturers like Tai An Hai Shu, allows for precise adjustments and reshaping of the dented hub. An elongated rod can facilitate automatic hydraulic reshaping, ensuring accuracy in the correction process.

6. What Should You Consider When Choosing a Rim Bending Machine?

6.1 Technical Specifications

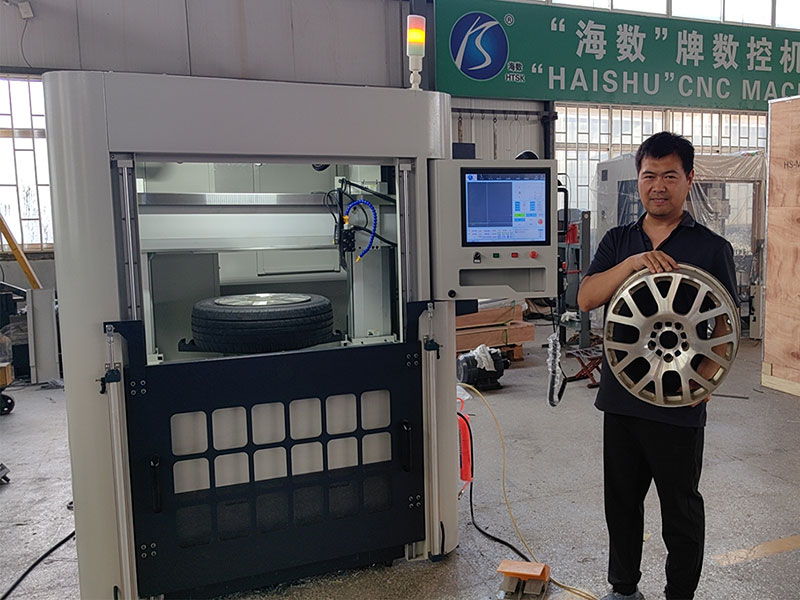

When selecting a rim bending machine, it’s essential to consider the technical specifications, including the machine’s capacity to handle various wheel sizes and materials. Look for features that enhance functionality, such as CNC capabilities for precision machining, which can further streamline the repair process.

6.2 Manufacturer Reputation

Opting for a reputable manufacturer, such as Tai An Hai Shu, known for producing high-quality wheel repair machines, aluminum wheel CNC lathes, and diamond cut wheel lathes, can make a significant difference in the machine’s performance and longevity.

7. Conclusion: Investing in a Rim Bending Machine

In summary, a rim bending machine is an invaluable tool for automotive repair professionals. Its ability to restore deformed wheel hubs saves costs and enhances safety and efficiency. For those interested in expanding their repair services, investing in a high-quality rim bending machine can provide reliable solutions for wheel restoration.

Consulting with a professional manufacturer like Tai An Hai Shu is recommended if you’re considering entering the wheel hub refurbishment or repair business. They offer robust technical support, efficient service, and a global network of agents and distributors. Customers are encouraged to visit the factory to witness the manufacturing strength and product quality firsthand.

By understanding the capabilities and benefits of a rim bending machine, you can make informed decisions that enhance your automotive repair services and meet customer needs effectively.