1. What Is a Rim Fixing Machine?

Understanding Rim Fixing Machines

A rim fixing machine is a specialized machine for repairing car wheel rims. During driving, wheels often suffer damages like rim deformation, dents, or cracks, which affect both performance and appearance. Rim fixing machines restore these wheels to their original condition, improving safety and aesthetics.

There are two primary types of rim fixing machines:

- Wheel Straightening Machines: These machines use hydraulic systems to correct deformations in alloy wheels.

- Wheel Repair Lathes: These CNC-based machines repair the spokes and rim surfaces by precision cutting.

Why Are Rim Fixing Machines Important?

Damaged rims can lead to poor driving performance, reduced safety, and diminished aesthetics. A wheel repair machine (Machine de Réparation de Roues) can resolve such issues quickly and efficiently. These machines are particularly beneficial for repair shops, car dealers, and manufacturers aiming to maintain high-quality wheel standards.

2. How Does a Rim Fixing Machine Work?

Wheel Straightening Machines

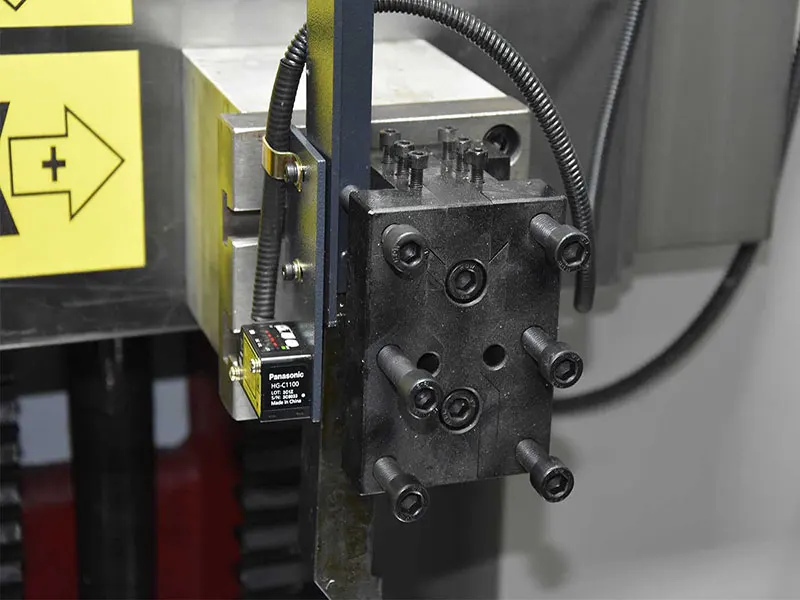

The wheel straightening machine is a vital component for repairing deformed rims. It primarily consists of the following parts:

- Faceplate: Adapts to various mounting holes to clamp wheels securely for repair.

- Crab Claw Fixtures: Pushes the deformed rim into shape using hydraulic power.

- Spindle and Tool Holder: Used for cutting and smoothing after reshaping.

The repair process involves heating the rim to soften the material, followed by hydraulic shaping with the crab claw fixtures. If the rim has cracks or missing parts, welding is done to restore the structure. The final step involves using the tool holder to cut any excess material, ensuring the rim matches factory specifications.

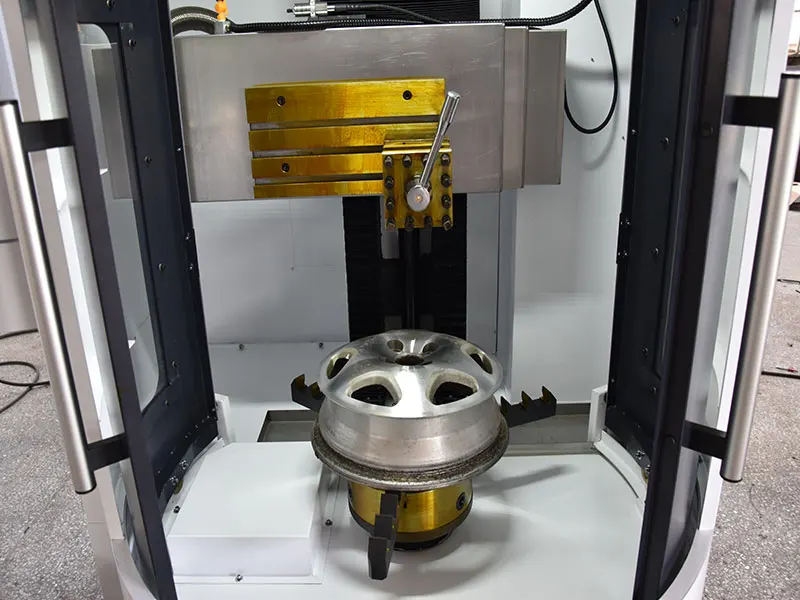

Wheel Repair Lathes

The wheel repair lathe (Máquina de Reparación de Ruedas)is indispensable for restoring the surface of the rim spokes. This CNC-based machine uses precision cutting tools to repair damaged spokes and enhance the wheel’s appearance. Taian Haishu’s CNC wheel repair lathe (휠 수리 기계)offers advanced features like laser detection, automatic optimization, and high-speed cutting for efficient and accurate repairs.

3. What Are the Features of a Rim Fixing Machine?

Key Features of Wheel Repair Machines

- Hydraulic Drive: In wheel straightening machines, hydraulic systems provide the strength needed to reshape rims effectively.

- Laser Detection: Found in advanced CNC wheel repair lathes (Tekerlek Tamir Makinesi), laser detection scans the wheel surface in just 15 seconds, ensuring precise cutting paths.

- Customizable Systems: Machines like Taian Haishu’s wheel repair lathe allow users to customize CNC programs, tool settings, and repair paths.

Taian Haishu’s Innovative Wheel Repair Machines (Rad reparatur maschine)

Taian Haishu is a leader in the wheel repair industry. Its products, including CNC wheel repair lathes (آلة إصلاح العجلات) and wheel CNC machines, stand out for their:

- User-Friendly Operation: Even beginners can master the system in 30 minutes.

- Efficiency: Repairs are 3–5 times faster than traditional methods.

- Customization: Supports multiple voltages (110V, 220V, 380V, 440V) and languages for global compatibility.

4. What Are the Benefits of Using Rim Fixing Machines?

Enhanced Repair Efficiency

Using a wheel repair machine (Máy Sửa Chữa Bánh Xe) significantly reduces repair time. For example, Taian Haishu’s CNC wheel repair lathe (Станок для ремонта колес) allows operators to complete complex repairs in a fraction of the time compared to traditional CNC machines.

Improved Precision and Quality

Wheel repair lathes (เครื่องซ่อมล้อ) provide unmatched precision with features like laser detection, automated optimization, and advanced tool holders. The repaired rims not only regain their structural integrity but also achieve a factory-like finish.

Cost Savings

Investing in a wheel CNC machine reduces operational costs in the long run. Faster repairs mean higher customer turnover, while the machine’s durability ensures minimal maintenance expenses.

5. What Are the Configurations and Models of Rim Fixing Machines?

Taian Haishu’s Rim Fixing Machine Models

Taian Haishu offers a wide range of CNC wheel repair machines to suit different repair needs. Popular models include:

- CK6160Q: Ideal for repairing standard passenger car rims.

- CK6160W: Comes with advanced features like real-time video recording for better monitoring.

- CKL22Q: Designed for larger wheels and heavy-duty repairs.

- CK6180A/CK6180W: Suitable for industrial-scale repairs and customization.

Customizable Configurations

Customers can enhance their wheel repair lathes with additional configurations, such as:

- Multi-jaw Chucks: For better clamping and stability.

- Servo Main Motors: Improves cutting speed and accuracy.

- Multi-functional Tool Holders: Expands the machine’s versatility for complex repairs.

6. Why Choose Taian Haishu Rim Fixing Machines?

Industry-Leading Technology

Taian Haishu’s wheel CNC machines feature cutting-edge technology, such as:

- Automatic and Manual Optimization: Adjust repair paths directly in the system without third-party tools.

- One-Key Tool Setting: Simultaneously sets X-axis and Z-axis coordinates for convenience.

- Program Storage: Stores up to 10,000 CNC programs, enabling repair shops to handle diverse customer requirements.

Comprehensive Support

With a global presence in Europe, America, South Korea, Australia, and South America, Taian Haishu provides:

- On-Site Services: Expert support for installation and training.

- Video Tutorials: Detailed guides for machine operations and maintenance.

- Lifetime Software Upgrades: Ensures customers always have access to the latest features.

Customer-Centric Design

Taian Haishu machines are built with user convenience in mind, offering:

- 17-Inch Touch Screens: Allows manual or mouse operation for flexibility.

- Multi-Language Systems: Supports any language for global usability.

- Voltage Customization: Compatible with various power standards worldwide.

Final Thoughts on Rim Fixing Machines

If you’re looking to enter the wheel repair business or upgrade your existing operations, investing in a reliable rim fixing machine is a must. Whether it’s a wheel straightening machine for reshaping rims or a CNC wheel repair lathe for precision spoke repairs, Taian Haishu offers industry-leading solutions tailored to your needs.

With decades of experience, innovative technology, and exceptional customer support, Taian Haishu has earned its reputation as a benchmark in the wheel repair industry. Explore their range of wheel repair lathes, wheel CNC machines, and wheel repair machines today to take your business to the next level!