What is a Rim Restoration Machine?

A Rim Restoration Machine, also known as a wheel repair lathe, wheel CNC machine, or wheel repair machine, is a specialized tool employed for repairing automotive rims that are deformed or scratched. These machines are essential in the automotive repair sector, ensuring that wheels are restored to their original condition, which enhances both the aesthetic appeal and the safety of the vehicle.

How Does a Rim Restoration Machine Enhance Wheel Repair Efficiency?

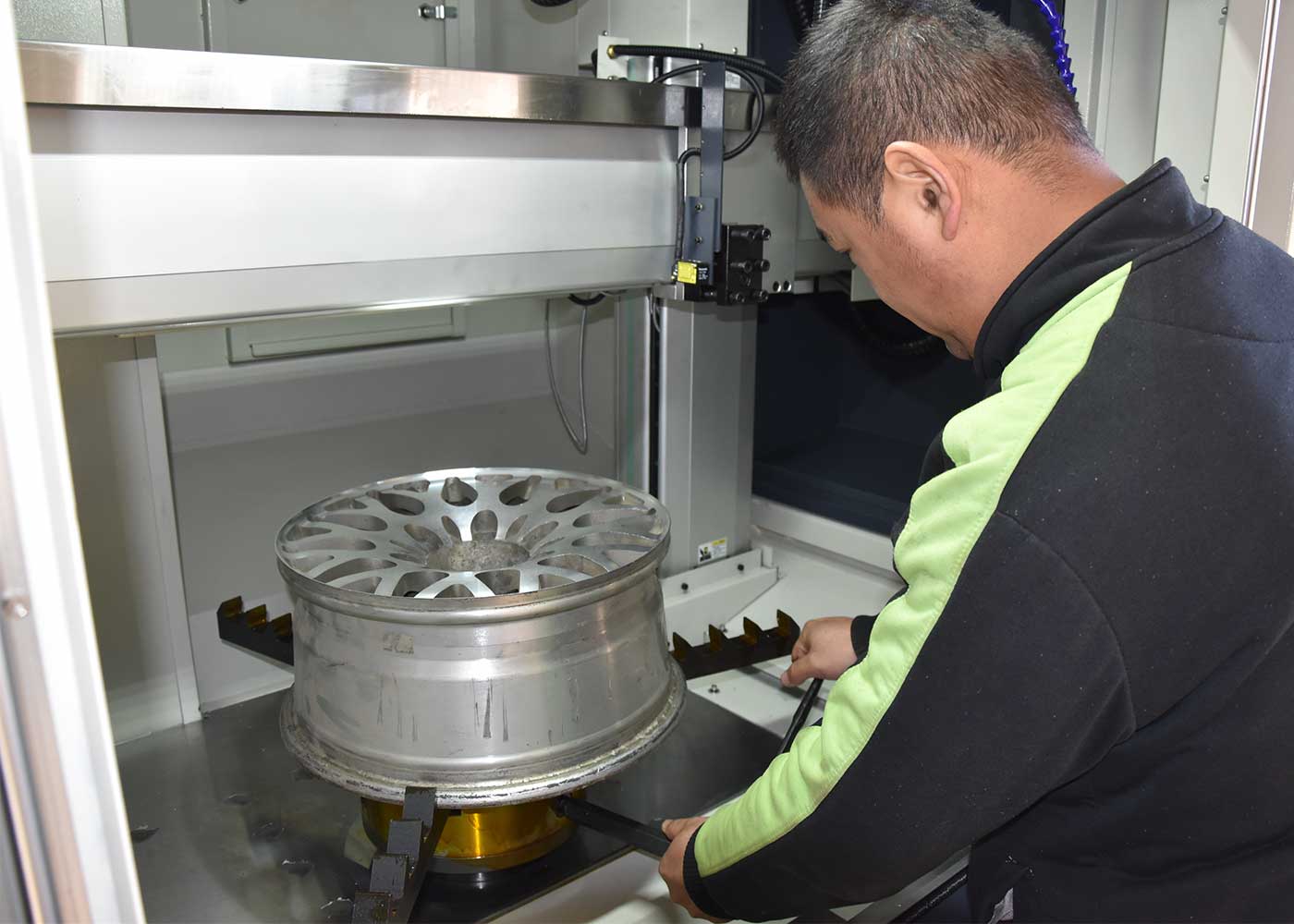

Rim Restoration Machines streamline the wheel refurbishment process significantly. The process begins with a wheel straightening device that corrects deformations on the rim. Once the rim is straightened, it is then placed on a wheel repair lathe. For larger rims, particularly those exceeding 22 inches, models like the HAISHU CKL22Q and CKL35 are preferred for their robust capabilities. These machines are equipped with precision wheel clamping and advanced detection systems that facilitate quick and accurate repairs. Automated features, such as one-click machining and automatic tool setting, reduce the time and skill required to restore a rim, which typically takes about 30 to 45 minutes per wheel.

What are the Types and Features of Rim Restoration Machines?

Rim Restoration Machines are available in various designs, including horizontal and vertical configurations. Horizontal wheel repair lathes are more cost-effective and are suitable for rims up to about 20 inches. However, for larger rims, vertical machines like the aforementioned HAISHU models offer greater stability, preventing vibrations or wobbling during the repair process. These machines are also equipped with specialized cutting tools that precisely restore the wheel to its factory specifications in terms of dimensions and surface smoothness. The ability to detect and optimize the cutting paths automatically ensures that the rim is repaired with high precision and minimal manual intervention.

How Does a Rim Restoration Machine Contribute to Customized Wheel Repair Solutions?

For businesses seeking to offer tailored solutions, Rim Restoration Machines provide significant adaptability. Manufacturers such as HAISHU offer professional ODM services, enabling companies to develop a branded rim restoration system that can cater specifically to the needs of their clientele. This flexibility allows repair shops to offer unique services, such as custom designs and finishes, distinguishing them in a competitive market. Additionally, the integration of CNC technology in these machines allows for intricate repairs and customizations that were not possible with older manual models, thereby enhancing the service range offered by automotive repair facilities.

In conclusion, the Rim Restoration Machine is not just a tool for restoring damaged wheels; it is a comprehensive solution that enhances the efficiency, precision, and customization of wheel repair services. By using such advanced equipment, automotive repair businesses can ensure high-quality results, promote sustainability by extending the lifespan of rims, and reduce waste, thereby contributing positively to environmental conservation.