What is a Top Automated Wheel Repair Lathe?

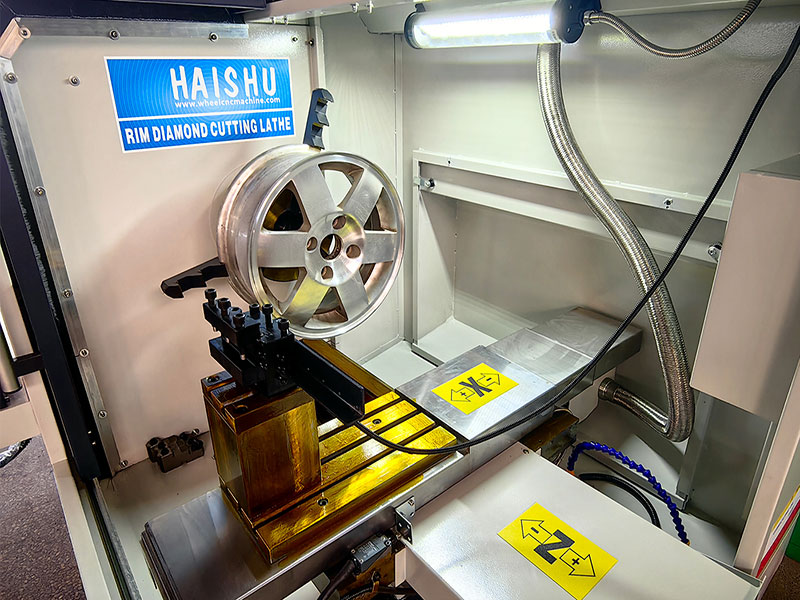

An automated wheel repair lathe is a specialized machine designed for repairing alloy wheels that have been scratched, deformed, or need refurbishing due to long-term driving or customer requests for wheel renewal. So, how has the top wheel CNC machine evolved in reality? This article will detail the development process of the Taian Haishu top wheel CNC lathe.

How Did the Top Automated Wheel Repair Lathe Evolve?

Initially, the most primitive wheel repair machines required manual point memory, manual programming, and manual tool setting. These early machines were particularly time-consuming and demanded extremely high skill levels from the operators. Without six months of learning and hands-on experience, a worker could not operate the machine independently. The advent of the top wheel repair lathe has been a boon for wheel refurbishment business owners and workers alike. Let’s focus on the distinctive features of the Haishu top automated wheel repair lathe.

What Are the Features of the Haishu Top Automated Wheel Repair Lathe?

Firstly, regarding the wheel repair system, Haishu has developed its own wheel refurbishment system, a completely self-designed and developed CNC system. This wheel repair system’s main feature is its ability to perform automatic detection, optimization, programming, tool setting, and machining. For detection, it uses a quick laser probe, which can automatically complete detection with a simple setting of the start and end points. These points can be set anywhere on the wheel, allowing customers to choose any position for refurbishment.

How Efficient is the Laser Detection in a Top Automated Wheel Repair Lathe?

How efficient is our laser detection? It takes only 15 seconds to complete the detection of the wheel surface. If customers require a contact-type probe, our repair system also supports that. Our self-developed detection system supports laser detection, probe detection, and tool tip detection simultaneously. Customers can choose their preferred detection method, making it very user-friendly.

What is the Path Optimization Process in a Top Automated Wheel Repair Lathe?

Secondly, the system provides fully automatic optimization of the path. After laser detection, it can automatically optimize the detected point path, simplifying the optimization steps to quickly complete and output the program. For those with strong manual skills, manual optimization is also supported. There’s no need to manually export the curves to a USB drive for external optimization; it can be done directly within the system.

How Does the Top Automated Wheel Repair Lathe Simplify CNC Programming?

Thirdly, the system can directly output the CNC program, eliminating the need for complex CNC programming. This is very user-friendly for those unfamiliar with CNC operations. It saves programming time, and even someone with no CNC background can master the operation within 30 minutes. Thus, our top automated wheel repair lathe significantly reduces technical requirements and saves customers a lot of money.

How User-Friendly is the Tool Setting Feature in a Top Automated Wheel Repair Lathe?

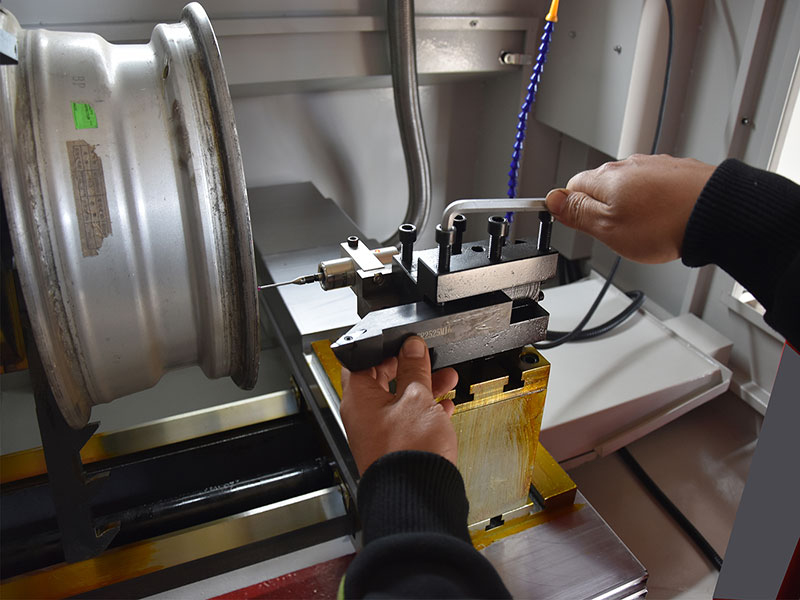

Fourthly, regarding tool setting, to make it easier for customers to accurately find the machining starting point, we have introduced a one-click tool setting feature. Customers do not need to input complex coordinates to easily find the starting point. This feature is the most user-friendly function to date.

What Additional Features Does the Top Automated Wheel Repair Lathe Offer?

Fifthly, after machining is completed, we thoughtfully provide customers with pneumatic cooling and cleaning configurations. This allows customers to blow away aluminum chips and clean the tool tip with a pneumatic cooling method after machining.

Why Choose the Haishu Top Automated Wheel Repair Lathe?

Our top wheel straightening lathe has many more configurations and customization features. If customers want more details about Haishu’s wheel refurbishment machines, they can browse our website or contact us via email. We will respond promptly.

The Evolution of Wheel Repair Technology

The journey from manual to wheel refurbishment lathe represents significant technological advancements. Initially, wheel repair was a laborious task requiring skilled technicians to manually program and operate the machines. The introduction of CNC technology revolutionized the industry by reducing the need for manual intervention and increasing precision.

CNC Technology in Wheel Repair

CNC (Computer Numerical Control) technology has played a crucial role in the development of the top automated wheel repair lathe. By allowing precise control over machining processes, CNC technology ensures that each wheel is refurbished to exact specifications. This not only improves the quality of repairs but also significantly reduces the time required for each job.

Benefits of Using a Top Automated Wheel Repair Lathe

Using a top mobile wheel repair lathe offers numerous benefits. Firstly, it enhances the efficiency of wheel repair processes by automating tasks such as detection, optimization, and programming. This reduces the reliance on skilled labor and minimizes the risk of human error. Secondly, the precision of CNC machining ensures a high-quality finish, extending the lifespan of refurbished wheels. Lastly, the user-friendly interface of modern lathes makes them accessible to operators with minimal training, further reducing operational costs.

Advanced Features of the Haishu Top Automated Wheel Repair Lathe

The Haishu top vertical wheel repair machine stands out due to its advanced features. The laser detection system, for instance, allows for quick and accurate surface scanning, enabling precise refurbishment. The automated path optimization feature streamlines the programming process, allowing for rapid and efficient machining. Additionally, the one-click tool setting feature simplifies the setup process, ensuring that operators can easily find the correct machining starting point.

Customization Options for the Haishu Top Automated Wheel Repair Lathe

One of the key advantages of the Haishu top CNC wheel lathe is its customization options. Customers can choose from various configurations to suit their specific needs. Whether it’s laser detection, probe detection, or tooltip detection, the system supports multiple methods to accommodate different preferences. The flexibility in detection methods ensures that customers can achieve the best possible results for their wheel refurbishment projects.

Enhancing Efficiency with the Haishu Top Automated Wheel Repair Lathe

Efficiency is a critical factor in wheel repair operations, and the Haishu top alloy wheel lathe excels in this area. The system’s ability to automatically optimize the detected point path reduces the time required for programming, allowing for quicker turnaround times. This is particularly beneficial for businesses looking to increase their throughput and meet customer demands more effectively.

Simplified CNC Programming with the Haishu Top Automated Wheel Repair Lathe

One of the standout features of the Haishu top wheel CNC lathe is its simplified CNC programming. The system’s ability to directly output CNC programs eliminates the need for complex programming knowledge, making it accessible to operators with minimal experience. This not only reduces training costs but also ensures that the machine can be operated efficiently by a wider range of personnel.

The Role of Pneumatic Cooling and Cleaning in the Haishu Top Automated Wheel Repair Lathe

Maintaining the cleanliness and functionality of the machine is essential for consistent performance. The Haishu top wheel CNC lathe includes pneumatic cooling and cleaning configurations to help achieve this. After machining, the pneumatic cooling system blows away aluminum chips and cleans the tooltip, ensuring that the machine remains in optimal condition for subsequent operations.

Conclusion

The Haishu top automated wheel repair lathe represents the pinnacle of wheel refurbishment technology. With its advanced features, user-friendly interface, and customization options, it offers unparalleled efficiency and precision. Whether you’re in the business of wheel repair, wheel straightening, or alloy wheel repair, investing in a top diamond cutting wheel lathe from Haishu can significantly enhance your operations. For more details about our wheel repair machines, visit our website or contact us via email. We are committed to providing prompt and comprehensive support to meet your needs.