What is a Top Vertical Wheel Cutting Lathe?

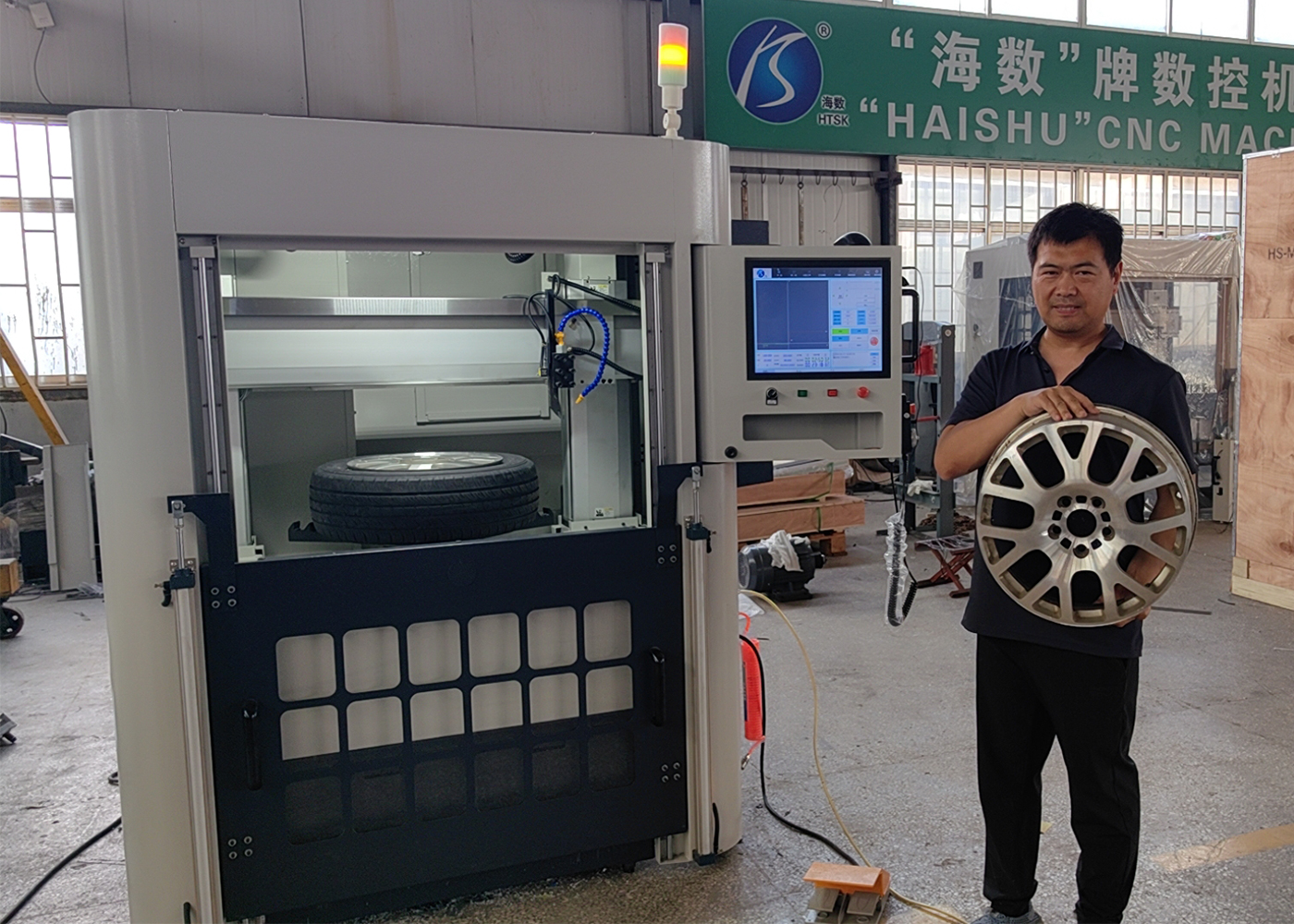

A top vertical wheel cutting lathe is a new type of CNC lathe specifically designed for repairing automotive alloy wheels. The need for such a machine arose because larger wheels, when placed on a horizontal wheel repair lathe, can experience edge vibrations during machining due to excessive centrifugal force. Thus, the top mini wheel repair lathe was developed to meet market demands. HAISHU was the first to develop a double-column gantry structure vertical wheel repair lathe. This article will highlight the advantages and features of HAISHU brand wheel repair lathes in the domain of vertical wheel lathes.

Why Choose a Top Vertical Wheel Cutting Lathe?

When it comes to alloy wheel repair, precision and stability are crucial. Larger wheels on a horizontal wheel repair lathe often suffer from edge vibrations during machining, which can compromise the quality of the repair. The top vertical wheel cutting lathe addresses this issue by providing a stable, vertically oriented platform that minimizes the impact of centrifugal force. This results in smoother, more accurate cutting and machining, making it the ideal choice for repairing automotive alloy wheels.

What Features Make the HAISHU Top Vertical Wheel Cutting Lathe Stand Out?

Specialized Wheel Repair System

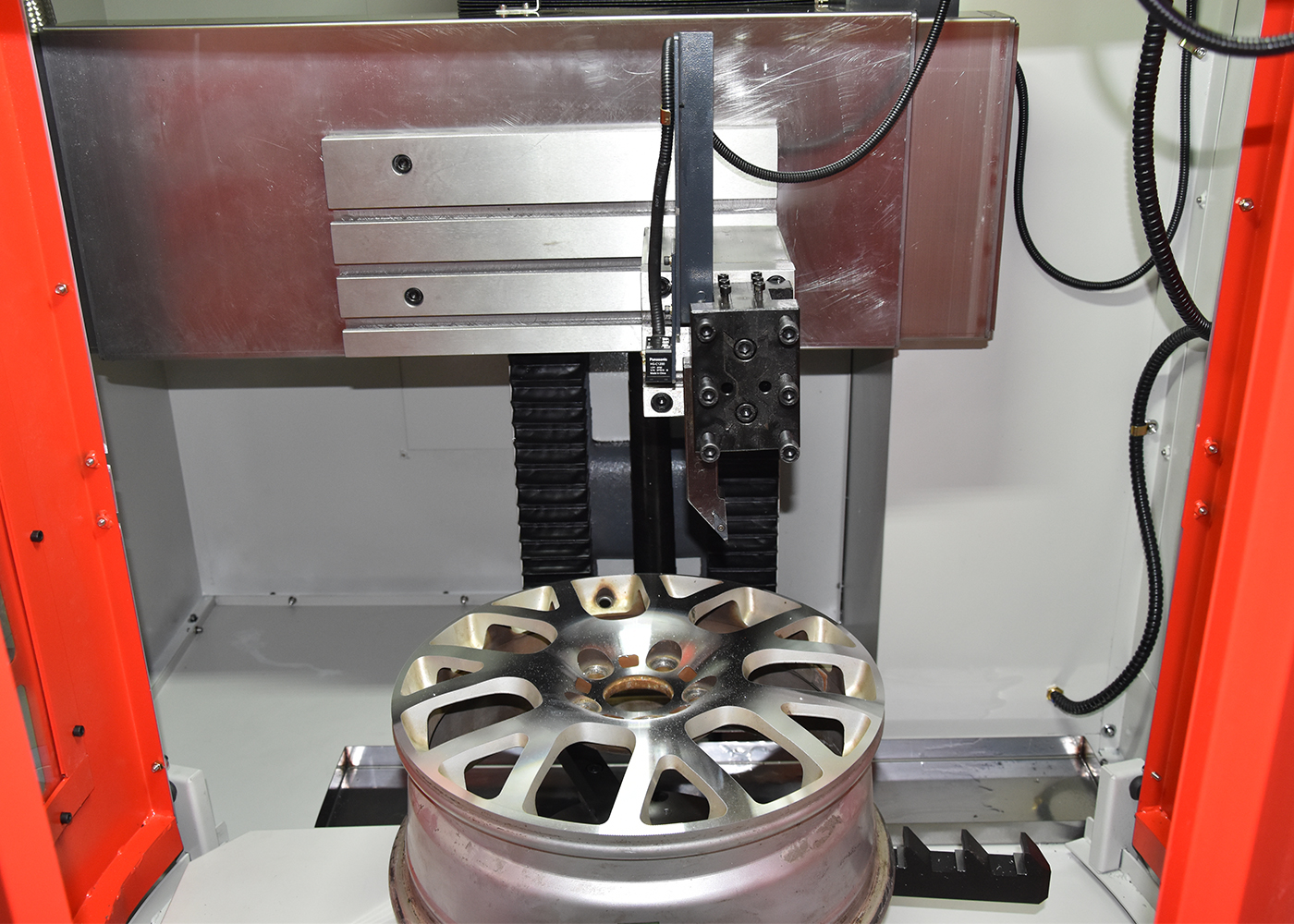

The most notable feature of the HAISHU top vertical wheel cutting lathe is its independently developed wheel repair system. It boasts a 17-inch touch screen and can also be controlled via mouse and keyboard. One unique aspect of our CNC system is its support for three detection methods: laser, probe, and tool tip, effectively covering all wheel surface shapes. Laser detection, the most frequently used and highly regarded by customers, can complete curve detection in just 15 seconds. It eliminates the need for complex optimization procedures, allowing for automatic or manual curve optimization and direct CNC program output. This system requires no CNC expertise from the operator, making it accessible even to those with zero CNC background. Additionally, the HAISHU CNC system can incorporate customer logos, including dealer logos, and supports any language worldwide.

Mechanical Components

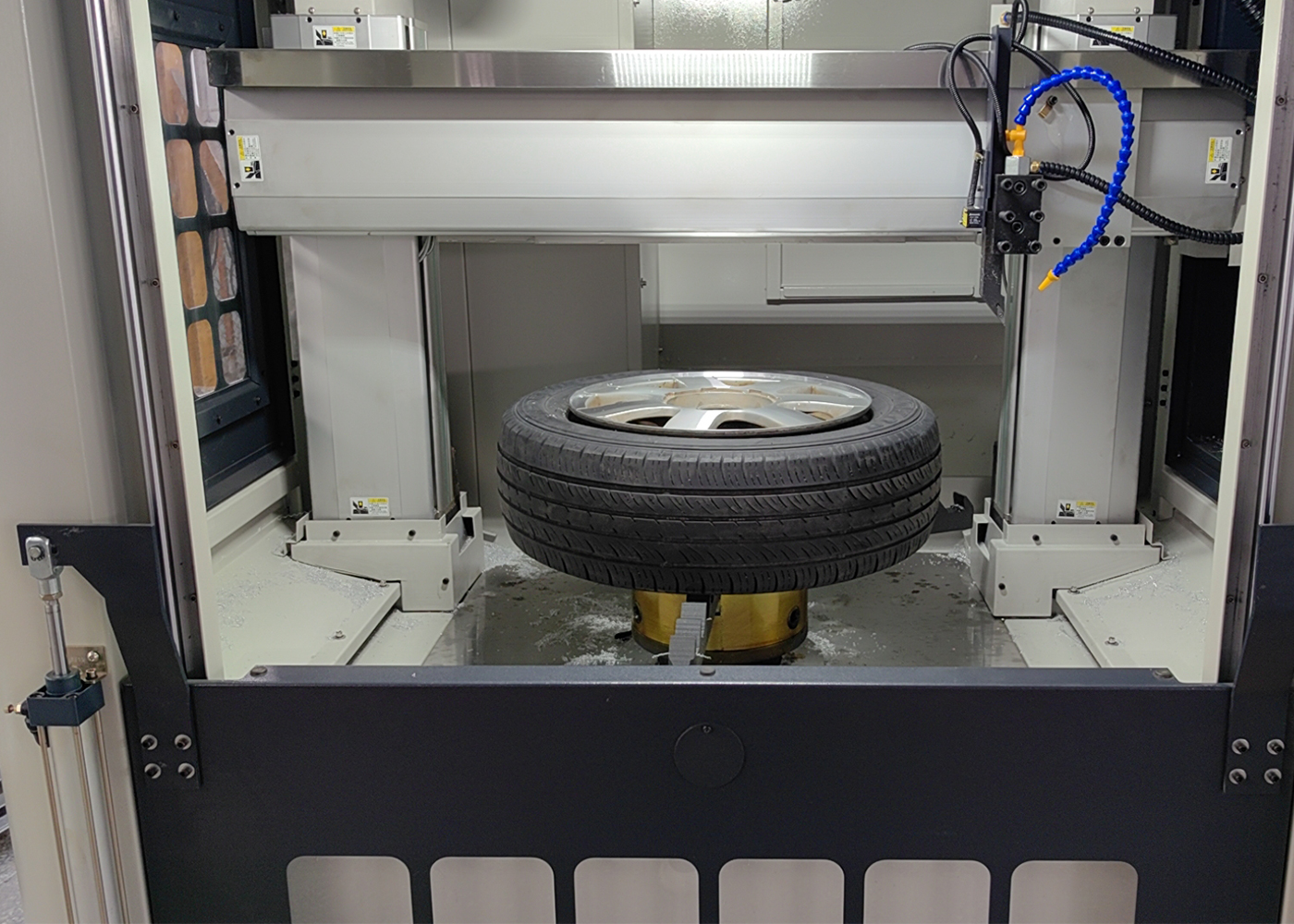

Moving to the mechanical aspects, HAISHU’s wheel CNC machine utilizes a spindle unit structure specifically designed for vertical lathes. This structure not only ensures stable rotation but also provides substantial load-bearing capacity, offering strong support for large chucks and wheels. The spindle pulley uses a synchronous belt drive to prevent loss of motor speed and torque, ensuring smooth power output.

Regarding rail transmission, we employ linear guide rail configurations, which are especially suited for machining aluminum alloy and non-ferrous metals. All three axes use linear guide rails: two Z-axes and an extended and widened X-axis, which also employs a three-point support method for fast, stable, and high-rigidity transmission.

The Z-axis adopts a double-column structure, commonly seen in gantry-style machines. Single-column structures lack the rigidity and load capacity for large automotive wheels, so HAISHU uses a gantry structure to meet various wheel machining needs. For added stability, we use an integrated cast iron base, providing a robust foundation.

Our tool post is made from integral profile material, which is lightweight and aesthetically pleasing. Although costly and challenging to manufacture due to the integral die-casting process, it offers strong rigidity and a refined appearance. For better sealing, we add protective covers to the profile material.

How Does the Top Vertical Wheel Cutting Lathe Enhance Wheel Repair?

The top vertical wheel cutting lathe enhances wheel repair by providing a stable and precise platform for cutting and machining. The vertical orientation minimizes the impact of centrifugal force, reducing-edge vibrations and ensuring smoother cuts. This not only improves the quality of the repair but also extends the lifespan of the wheels. The advanced detection methods and CNC systems allow for precise measurements and adjustments, making the repair process more efficient and effective.

What Additional Features Does the Top Vertical Wheel Cutting Lathe Offer?

Additional features of the HAISHU wheel repair machine include MPG for easy tool carriage movement, a three-color light for real-time processing progress monitoring, a pneumatic cooling system, and pneumatic lifting doors. Optional features include a servo main motor, four-position tool post, mobile wheels, four-jaw chuck, and voltage customization for 110V/220V/380V/415V.

How Customizable is the Top Vertical Wheel Cutting Lathe?

We can customize the top vertical wheel cutting lathe according to customer needs and welcome feedback. The system allows for the addition of customer logos, including dealer logos, and supports any language worldwide. This level of customization ensures that the machine can be tailored to meet the specific requirements of any operation, making it a versatile tool for alloy wheel lathe applications.

What Makes the HAISHU Top Vertical Wheel Cutting Lathe Stand Out?

HAISHU’s top vertical wheel-cutting lathe stands out due to its advanced features and robust construction. The use of a double-column gantry structure provides exceptional stability and load-bearing capacity, while the integrated cast iron base ensures a solid foundation. The independently developed wheel repair system, with its 17-inch touch screen and multiple detection methods, offers unparalleled precision and ease of use. These features, combined with the ability to customize the machine to meet specific needs, make HAISHU’s lathe the top choice for wheel repair.

Where Can You See the Top Vertical Wheel Cutting Lathe in Action?

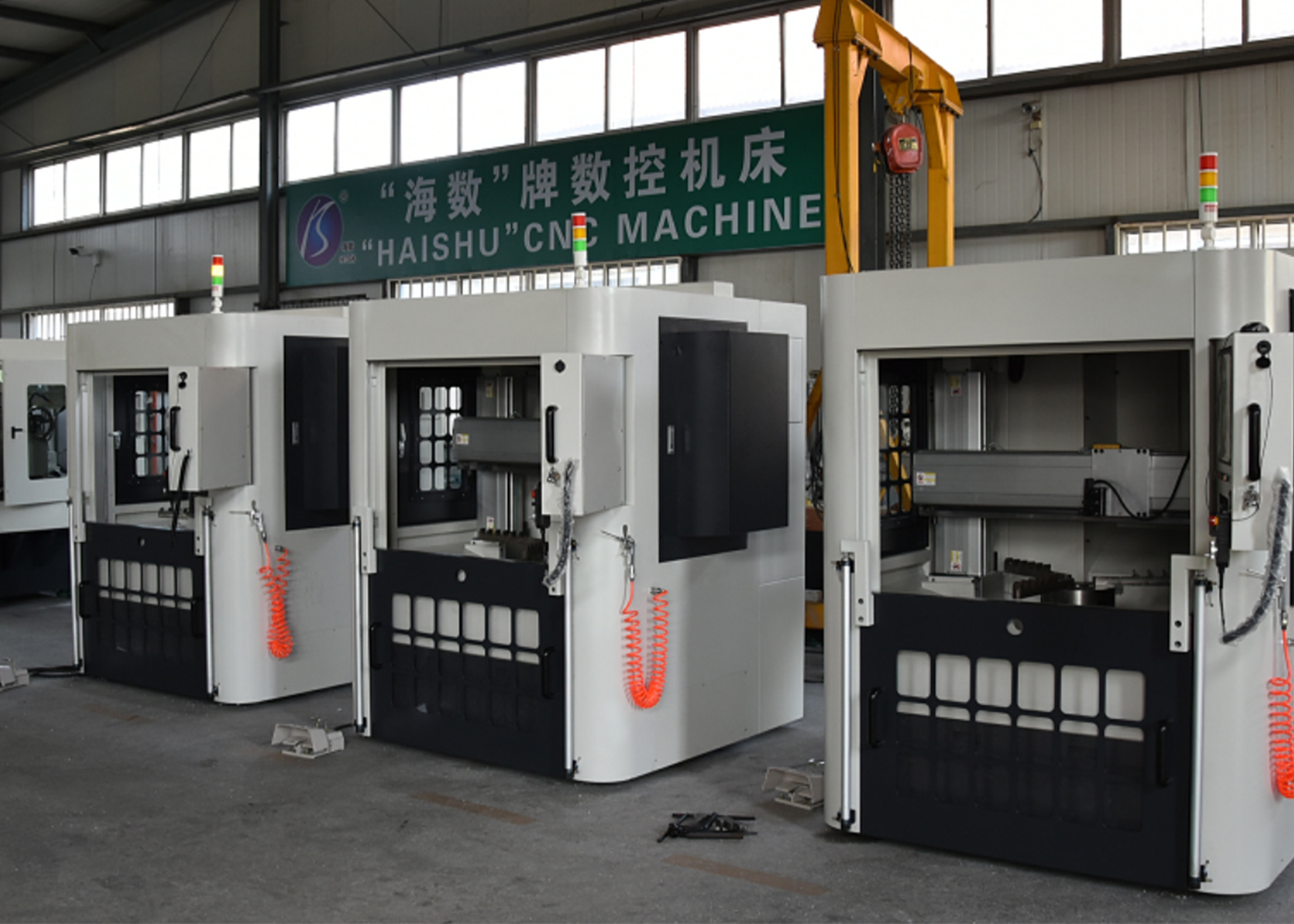

We invite more customers to visit our production facility to see the top diamond cutting wheel lathe in action. We can provide detailed product demonstration and operation videos, showcasing the machine’s capabilities and features. Our service team is available 24/7 to assist with any questions or concerns, ensuring that customers have all the information they need to make an informed decision.

Why is HAISHU the First Choice for a Top Vertical Wheel Cutting Lathe?

With sales in over 100 countries and regions, HAISHU has established itself as a leader in the wheel repair lathe industry. Our commitment to innovation and customer satisfaction sets us apart from the competition. The top mobile wheel repair lathe is a testament to our dedication to providing high-quality, customizable machines that meet the evolving needs of the market. When choosing a vertical wheel machining lathe, HAISHU is the first choice.

What Benefits Does the Top Vertical Wheel Cutting Lathe Provide?

The benefits of using a top portable wheel lathe for alloy wheel repair are numerous. By offering a stable and precise platform, it minimizes the impact of centrifugal force, resulting in smoother cuts and higher-quality repairs. The advanced detection methods and user-friendly CNC system streamline the repair process, making it more efficient and effective. The machine’s robust construction and customizable features ensure long-lasting performance and versatility, making it a valuable addition to any wheel repair operation.

Conclusion

In conclusion, the HAISHU top wheel lathe is the ultimate solution for alloy wheel repair. Its advanced features, robust construction, and customizable options make it the top choice for businesses looking to enhance the quality and efficiency of their wheel repair operations. With a commitment to innovation and customer satisfaction, HAISHU provides unparalleled support and service, ensuring that your investment in a top CNC wheel repair lathe delivers long-lasting benefits for your business. Visit our production facility, explore our detailed product demonstrations, and discover why HAISHU is the first choice for a top vertical wheel cutting lathe.