What is a Top Wheel Rim Repair Machine?

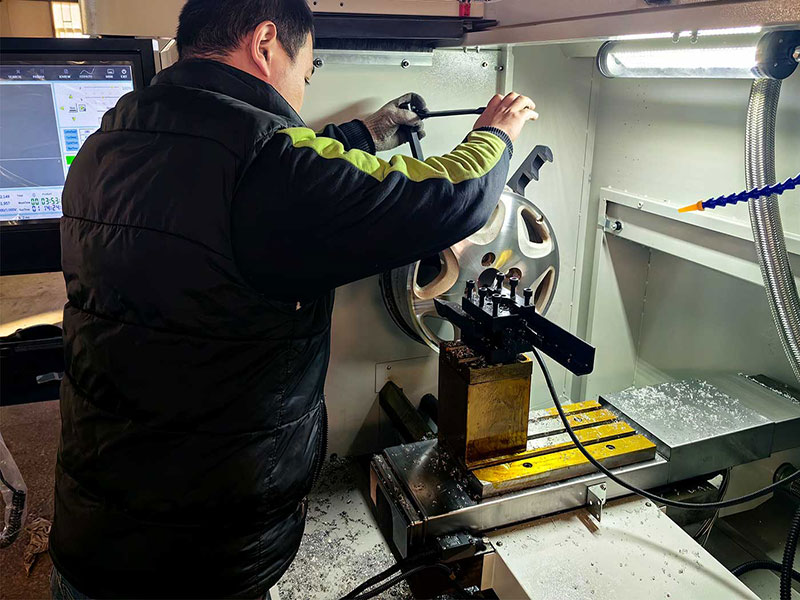

A top wheel rim repair machine is a specialized tool, akin to a CNC lathe, designed for the restoration of automotive alloy wheels. Its advent has breathed new life into alloy car wheels that have suffered from scratches or deformation, thereby preserving the resale value of second-hand cars. It also offers enthusiasts new ways to customize their car wheels. This article will introduce the configurations and features of the alloy wheel repair machine from Taian Haishu Company.

How Does a Top Wheel Rim Repair Machine Work?

Firstly, Haishu’s diamond cut wheel machine system is entirely self-developed. It breaks away from the traditional CNC lathe model, using a 17-inch touch screen. Coupled with functions such as automatic detection, automatic optimization, and automatic tool setting, even a novice can fully master the complex wheel repair process within 30 minutes. This innovative approach ensures that anyone, regardless of their technical background, can operate the wheel repair lathe effectively.

What Makes the Laser Detection Feature on a Top Wheel Rim Repair Machine So Special?

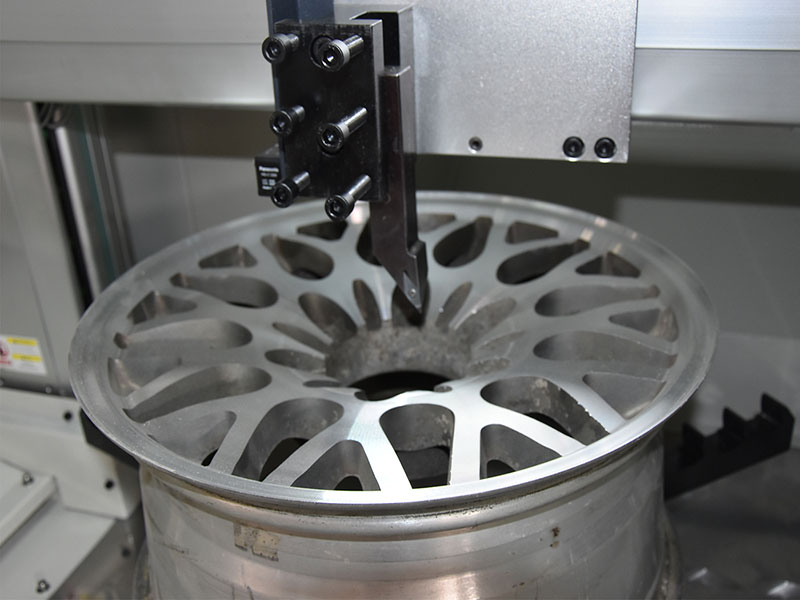

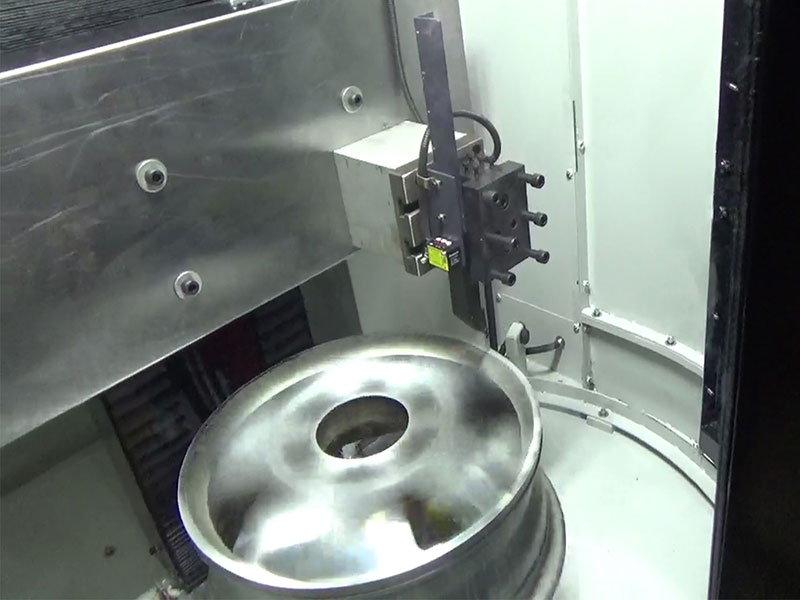

The laser detection in the automatic detection feature is the most popular. Traditional contact probes often have shortcomings like long detection times, broken probes, and deformed probes. With laser detection, the non-contact method makes wheel detection safer and more efficient, completing complex wheel surface detection in just 15 seconds. This quick and precise detection process is crucial for ensuring the accuracy of the repair, making it a standout feature of the top-wheel rim repair machine.

What Are the Optimization Options Available on a Top Wheel Rim Repair Machine?

After detection, it can automatically switch to the optimization interface without needing to transfer the surface path to a USB. Optimization can be done directly in the system, with options for automatic and manual optimization. Automatic optimization is suitable for relatively smooth wheel surfaces, while manual optimization is for more complex surfaces, allowing customers to choose based on their preferences. This dual optimization capability ensures that the wheel CNC machine can handle a wide range of wheel repair scenarios, from simple touch-ups to intricate restorations.

How Does a Top Wheel Rim Repair Machine Simplify CNC Programming?

The automatic output of CNC programs is another highlight. Operators do not need a solid foundation in CNC programming. Haishu’s top wheel rim repair machine can directly output machining programs with one click. The one-click tool setting mode simplifies both machining and programming, greatly enhancing the overall machining experience. This user-friendly approach reduces the learning curve and allows operators to focus more on the quality of the repair rather than the intricacies of programming.

What Are the Tool Holder Configurations on a Top Wheel Rim Repair Machine?

Regarding the tool holder configuration, Haishu uses the most economical and stable straight-line tool holder, which requires no maintenance or replacement and has no fault points. Even if replacement is needed, it is very simple, reducing both failure rates and maintenance costs. Haishu also offers manual and electric four-position tool holders as options. This flexibility in tool holder configurations allows users to choose the setup that best suits their specific repair needs, enhancing the machine’s versatility. The alloy wheel lathe setup ensures precision and stability during the repair process.

How Does a Top Wheel Rim Repair Machine Handle Chuck Clamping?

In terms of chuck clamping, Haishu has developed various extended claws for different wheel clamping needs, such as three-claw or four-claw, straight or curved claws. Haishu recommends using three claws as three-point support is the most stable. This variety of clamping options ensures that the top wheel rim repair machine can securely hold wheels of different sizes and shapes, providing a stable platform for precise repairs. This feature is particularly beneficial for a wheel repair machine aiming to deliver consistent results.

What Are the Unique Bed and Guide Rail Structures of a Top Wheel Rim Repair Machine?

Moreover, the bed and guide rail bed are also unique highlights of Haishu. They have developed various bed structures, including horizontal and vertical configurations, and for large car wheels, a fixed-beam gantry structure to accommodate large spans and increase rigidity. The guide rails are divided into hard rails and linear guide rails, with the latter being particularly suitable for alloy wheel machining and repair, enhancing brightness and smoothness. This robust design ensures that the machine can handle rigorous use while maintaining high precision and durability. These features make the wheel CNC lathe a reliable choice for any repair shop.

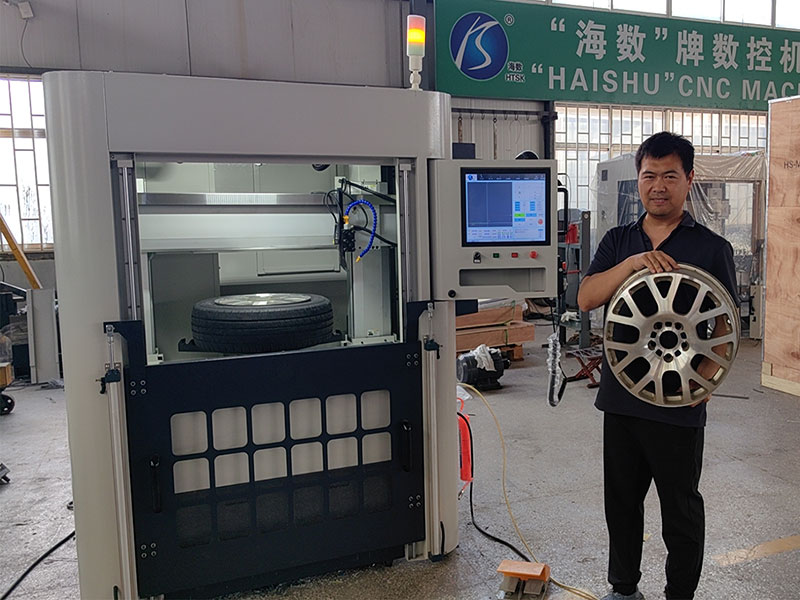

Why Choose a Top Wheel Rim Repair Machine from Haishu?

However, this article alone cannot fully introduce and showcase the technical and aesthetic innovations of the Taian Haishu top-wheel rim repair machine. The technical content is too complex to be fully conveyed through an article. You can also follow Haishu’s video channel or visit their website for more information. Haishu also offers various customization services, allowing customers to own a top-wheel rim repair machine that reflects their brand. By choosing Haishu, customers benefit from a combination of cutting-edge technology, user-friendly design, and customizable options that cater to a wide range of repair needs.

Conclusion

The alloy wheel repair lathe from Taian Haishu Company represents a significant advancement in the field of wheel repair. By integrating advanced features such as laser detection, automatic optimization, and simplified CNC programming, Haishu has created a user-friendly system that makes complex wheel repairs accessible even to novices. The diverse tool holder configurations and unique bed and guide rail structures further enhance the machine’s appeal, making it a versatile and reliable choice for both professional workshops and automotive enthusiasts. To fully appreciate the capabilities and innovations of Haishu’s top wheel rim repair machine, prospective users are encouraged to explore additional resources provided by the company, including videos and detailed product descriptions available on their website.