1. What is a Wheel Restore Machine?

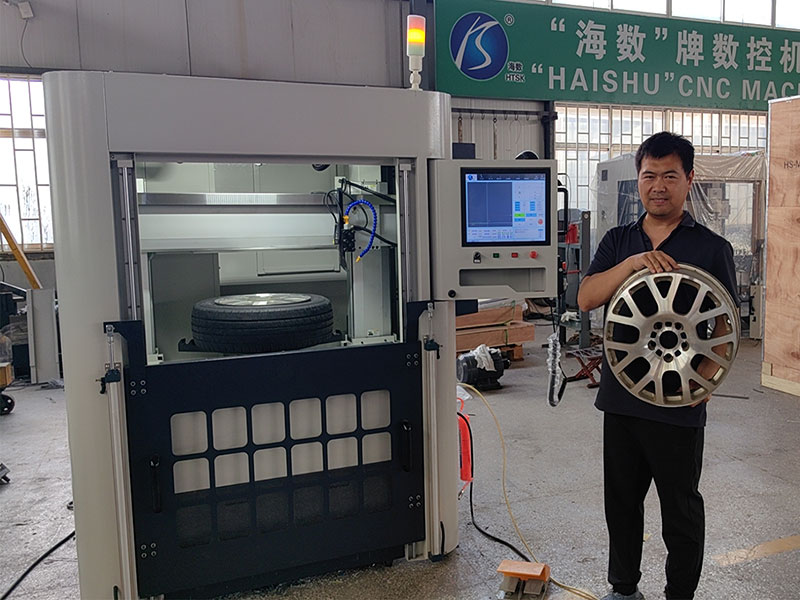

A wheel restore machine is a specialized CNC machine designed to repair wheel rims that have surface scratches, dents, or deformations. After performing aluminum welding to correct deformations, the machine uses CNC technology to cut or process the wheel surface. This equipment is primarily used in auto repair shops, 4S stores, and car beauty shops. It is also one of the mainstream wheel repair lathes in the current automotive repair market. Let’s take a closer look at HAISHU’s wheel CNC machine.

2. What Are the Main Components of a Wheel Restore Machine?

The wheel restore machine mainly consists of three parts: the wheel repair system, the tool holder, and the fixture. HAISHU has developed several horizontal and vertical wheel repair machines, including models such as CK6160Q, CK6160W, CK6180A, CK6180W, CKL22Q, and CKL35. The variety of models is designed to accommodate wheel rims of different sizes.

2.1 Wheel Repair System

The CNC repair system is developed by HAISHU and is specifically used for CNC wheel processing. Unlike complicated CNC programming, it replaces complex programming with simple one-click operations, allowing operators to master the system within 30 minutes, even without a CNC background.

HAISHU’s wheel repair system uses a 17-inch touch screen and eliminates the need for manual memory of CNC coordinates. Instead, it employs one-click detection, such as laser detection and probe detection. Laser detection, which takes only 15 seconds to complete the detection of the wheel surface, is particularly popular. In contrast, traditional methods require manual memory of coordinates and programming, which can take over 30 minutes. Thus, HAISHU’s new laser detection method is widely preferred.

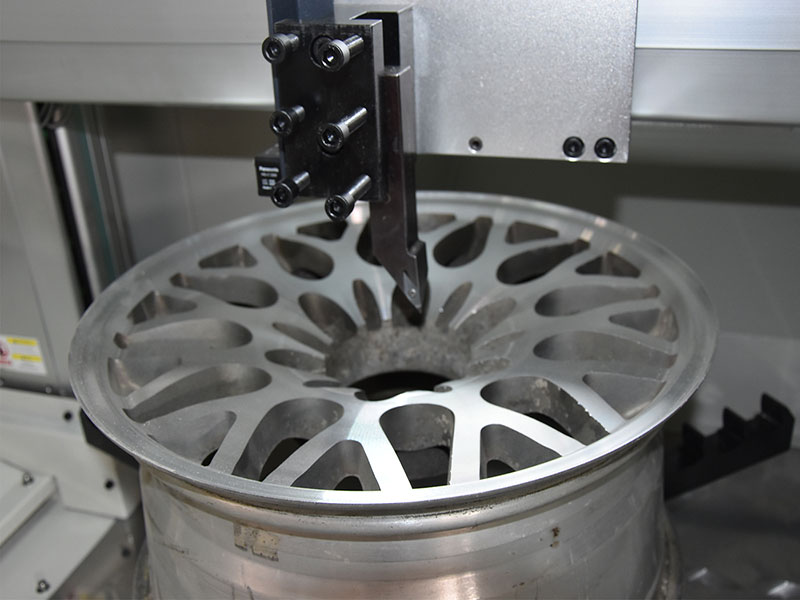

3. What Are the Different Types of Tool Holders in a Wheel Restore Machine?

Regarding the wheel processing tool holder, we offer various options, each with its own characteristics. The most cost-effective is the linear tool holder, which can directly install tools and laser probes. Its main advantages are economy, stability, and ease of replacement. We also offer a manual four-station tool holder, which allows for manual switching of tools and angles, making it adaptable to different wheel curves. However, it is more costly than the linear tool holder and requires more labor for replacement. The third option is the automatic tool holder, which can automatically switch tools through the CNC wheel repair system, offering convenience and speed. However, it is the most expensive option, and any damage can render the entire machine unusable. Therefore, customers should carefully consider their choice of configuration.

3.1 Linear Tool Holder

The linear tool holder is the most economical option. It can directly install tools and laser probes, offering stability and ease of replacement. This type of tool holder is ideal for those looking for a cost-effective solution without compromising on quality.

3.2 Manual Four-Station Tool Holder

The manual four-station tool holder allows for manual switching of tools and angles, making it adaptable to different wheel curves. However, it is more costly and labor-intensive than the linear tool holder.

3.3 Automatic Tool Holder

The automatic tool holder can switch tools automatically through the CNC wheel repair system. This option offers convenience and speed but is the most expensive and can render the machine unusable if damaged.

4. What Are the Features of the Fixture in a Wheel Restore Machine?

HAISHU uses precision wire-cutting technology for CNC processing of the wheel fixture, designing extended fixtures to accommodate different wheel sizes. The fixtures are toothed and hook-shaped, ensuring a firm grip on the wheel. Various types of fixtures are available, including straight, curved, and multi-layered, allowing users to choose according to their needs.

4.1 Precision Wire Cutting Technology

HAISHU employs precision wire-cutting technology for CNC processing, ensuring high-quality and accurate fixtures. This technology allows for the creation of complex shapes and designs.

4.2 Extended Fixtures

Extended fixtures are designed to accommodate different wheel sizes. The toothed and hook-shaped design ensures a firm grip on the wheel, preventing slippage during the repair process.

4.3 Variety of Fixture Types

HAISHU offers a variety of fixtures, including straight, curved, and multi-layered options. Users can choose the type that best suits their needs and preferences.

5. What Are the Different Wheel Detection Methods Used in a Wheel Restore Machine?

The wheel detection method is also distinctive. Most users prefer laser probes, which can perform non-contact detection to avoid collisions and offer fast detection speeds. Laser data is automatically collected to form the surface data of the wheel. The second option is a contact probe, which directly contacts the wheel surface to send different distance signals, forming the wheel curve. This method offers slightly higher detection precision but takes longer and is prone to collisions, with higher replacement and maintenance costs. The third method, uniquely developed by HAISHU, uses the tip of the processing tool for detection. The tool holder moves directly to the processing surface, and the coordinates are automatically memorized to form the wheel surface. Although it has the highest detection precision and is suitable for complex wheel surfaces, it takes longer.

5.1 Laser Probes

Laser probes perform non-contact detection, avoiding collisions and offering fast detection speeds. Laser data is automatically collected, forming the surface data of the wheel. This method is popular due to its speed and accuracy.

5.2 Contact Probes

Contact probes directly contact the wheel surface to send different distance signals, forming the wheel curve. While this method offers slightly higher detection precision, it takes longer and is prone to collisions, with higher replacement and maintenance costs.

5.3Tool Tip Detection

Uniquely developed by HAISHU, tooltip detection uses the tip of the processing tool for detection. The tool holder moves directly to the processing surface, and the coordinates are automatically memorized to form the wheel surface. This method offers the highest detection precision but takes longer.

6. What Advantages Does the HAISHU Wheel Restore Machine Offer?

Through this article, we can get a general understanding of the configuration and functions of HAISHU’s wheel restore machine. However, this is not an exhaustive overview. In future articles, we will discuss the bed structure of HAISHU’s wheel repair lathe, including horizontal and vertical structures. We invite you to follow our official website and share your repair requirements with us. We can provide ODM services and welcome you to visit our company for a tour.

6.1 High Precision and Efficiency

HAISHU’s alloy wheel lathe offers high precision and efficiency in wheel repair. The advanced CNC technology ensures accurate and consistent results, making it a reliable choice for professional wheel repair services.

6.2 User-Friendly Interface

The user-friendly interface, featuring a 17-inch touch screen, simplifies the wheel repair process. Operators can master the system within 30 minutes, even without prior CNC experience.

6.3 Versatility

HAISHU offers a variety of models and configurations to accommodate different wheel sizes and repair needs. This versatility makes it suitable for auto repair shops, 4S stores, and car beauty shops.

7. How Can You Benefit from Using HAISHU’s Wheel Restore Machine?

Using HAISHU’s wheel restore machine can significantly enhance your wheel repair capabilities. The advanced features and high precision of the machine ensure top-quality repairs, attracting more customers and boosting your revenue.

7.1 Increased Productivity

The one-click detection and automatic tool-switching features reduce downtime and increase productivity. Operators can complete repairs quickly and efficiently, allowing for more work to be done in less time.

7.2 Cost-Effective Solutions

The variety of tool holders and fixtures offered by HAISHU provides cost-effective solutions for different repair needs. Customers can choose the configuration that best suits their budget and requirements.

7.3 Professional Support

HAISHU offers professional support, including software updates, technical training, and ODM services. Customers can rely on HAISHU for comprehensive assistance and high-quality products.

In conclusion, HAISHU’s wheel straightening machine are a valuable investment for any business in the wheel repair industry. With their advanced features, high precision, and user-friendly design, these machines offer an efficient and reliable solution for repairing wheel rims. Follow our official website for more information and updates on HAISHU’s products and services.