1. What is an Aluminum Wheel Repair Machine?

An aluminum wheel repair machine is an essential tool in the automotive industry, specifically designed for repairing alloy rims on vehicles. These rims often suffer from various forms of damage, including scratches and impacts, which can lead to deformation and a decrease in the vehicle’s overall value.

1.1 The Importance of Aluminum Wheel Repair

Repairing damaged rims is crucial not only for aesthetics but also for safety. A well-maintained wheel ensures proper vehicle handling and performance. The aluminum wheel repair machine addresses these issues effectively through advanced technology.

2. How Does the Aluminum Wheel Repair Machine Work?

The aluminum wheel repair machine typically combines several functionalities, including rim shaping machines and rim repair lathes.

2.1Steps Involved in Wheel Repair

Reshaping Deformed Rims: If a car’s rim is deformed, the first step is to use a rim correction machine. This machine reshapes the rim to restore its original form.

Heating and Reshaping: For severe deformations, the damaged area is heated with a heat gun. A hydraulic jack equipped with a Taiwanese hydraulic valve is then used for reshaping. The heating process makes it easier to manipulate the aluminum.

Welding Missing Pieces: If parts of the rim are missing, specialized aluminum welding techniques come into play. This process fills in the gaps left by damage, setting the stage for further repairs.

3. What Are the Key Features of Haishu’s Aluminum Wheel Repair Machine?

Taian Haishu’s aluminum wheel CNC lathe is renowned for its innovative features that enhance the repair process.

3.1 Advanced Mounting Options

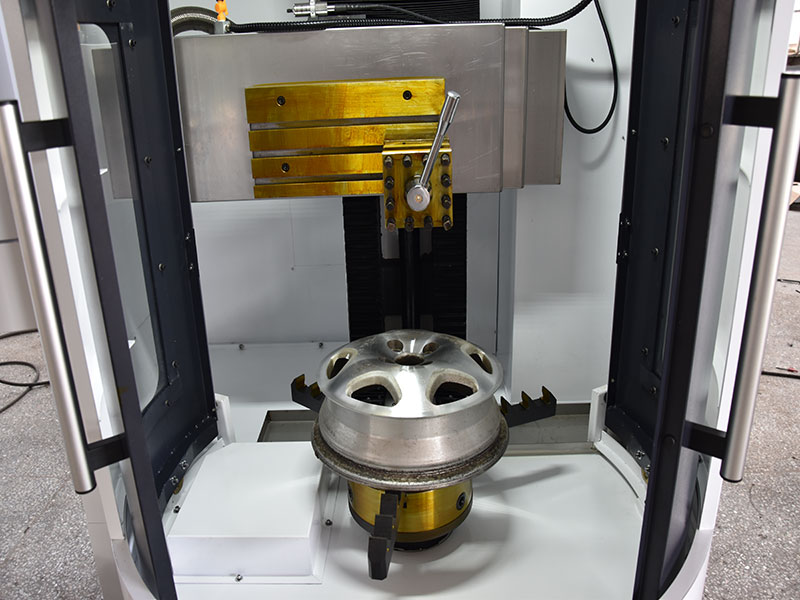

The machine is equipped with a special three-jaw chuck and extended fixtures, enabling quick and efficient mounting of rims. Additionally, it supports a central axis mounting method, which improves stability during repair.

3.2 Laser Detection Program

One of the standout features is the laser detection program, which can complete a detection cycle in just 15 seconds. This rapid assessment allows for quick identification of the rim’s condition, ensuring timely repairs.

4. How Does CNC Technology Enhance Rim Repair?

CNC technology plays a significant role in modern aluminum wheel repair machines, particularly in enhancing precision and efficiency.

4.1 CNC Programming Capabilities

Haishu has upgraded its CNC programming capabilities, allowing users to optimize machining paths with ease. The one-click program output feature is particularly beneficial for those with limited CNC knowledge. This innovation allows even beginners to achieve precise CNC programming, facilitating immediate adjustments to coordinates.

4.2 Automatic and Manual Optimization

Clients can choose between automatic and manual optimization for refining detected curves. Automatic optimization generates curves that accurately match the detected surface, while manual optimization allows for tailored adjustments according to specific customer needs.

5. What Role Does the Wheel Repair Lathe Play?

The wheel repair lathe is a critical component of the aluminum wheel repair machine, serving as a dedicated tool for precision machining.

5.1 Precision Machining Process

Once the preliminary repairs and shaping are completed, the rim is mounted on the wheel repair lathe. Specialized tools are employed to cut and refine the rim surface, ensuring a smooth and even finish.

5.2 Benefits of Using a Wheel CNC Machine

Using a wheel CNC machine enhances the accuracy of the repair process. The CNC capabilities ensure that even complex rim shapes can be machined with precision, reducing the risk of further damage during repairs.

6. How Does Haishu Ensure Quality in Aluminum Wheel Repairs?

Quality is paramount in aluminum wheel repairs, and Haishu has developed several features to guarantee that every repair meets high standards.

6.1 Pneumatic Cleaning Function

After CNC machining, aluminum chips can accumulate on the rim surface. Haishu’s pneumatic cleaning function utilizes a handheld tool to blow away these chips, ensuring a clean finish. This function also cools the tool while removing debris, enhancing the overall efficiency of the repair process.

6.2 Customization Options

Taian Haishu offers an ODM model that allows for customization of voltage, appearance, functionalities, logo, and language. This flexibility has enabled Haishu to establish partnerships in over 90 countries and regions, catering to diverse market needs.

7. Why Choose Haishu’s Aluminum Wheel Repair Machine?

Choosing Haishu’s aluminum wheel repair machine means investing in state-of-the-art technology that guarantees high-quality repairs.

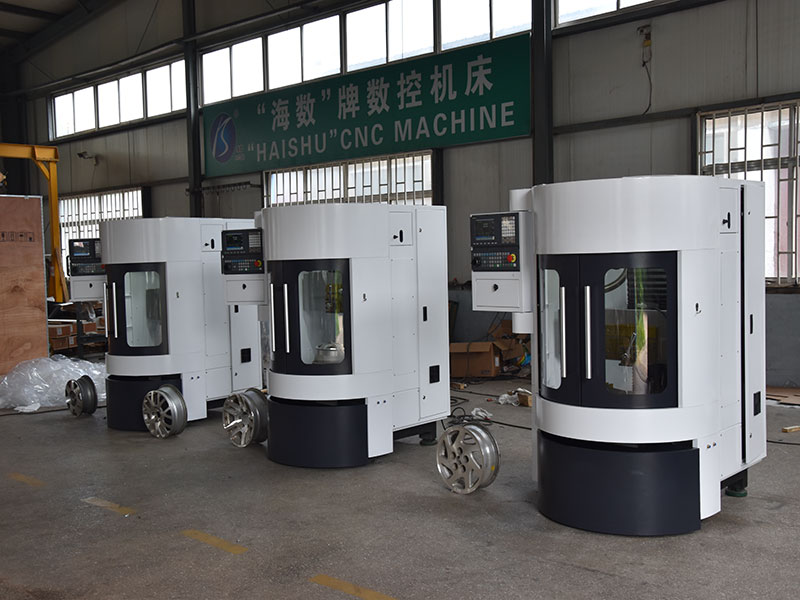

7.1 Visit the Haishu Factory

Potential clients are encouraged to visit Haishu’s manufacturing facility to gain a comprehensive understanding of the aluminum wheel repair machine. As the manufacturers, Haishu takes pride in showcasing their advanced technology and robust production processes.

7.2 Contact for More Information

For more information about Haishu’s diamond cut wheel lathe, including details on the wheel repair lathe and CNC alloy wheel repair capabilities, feel free to contact us directly. Our team is ready to assist you with any inquiries.

8. Conclusion

In summary, the alloy repair machine is an indispensable tool for auto repair shops, ensuring that damaged alloy rims can be restored to their former glory. With features like CNC technology, laser detection, and pneumatic cleaning, Taian Haishu’s machine stands out as a leader in the industry. Whether for personal or professional use, investing in a quality aluminum wheel repair machine is essential for maintaining the safety and appearance of vehicles.