1. What is CNC on Wheels?

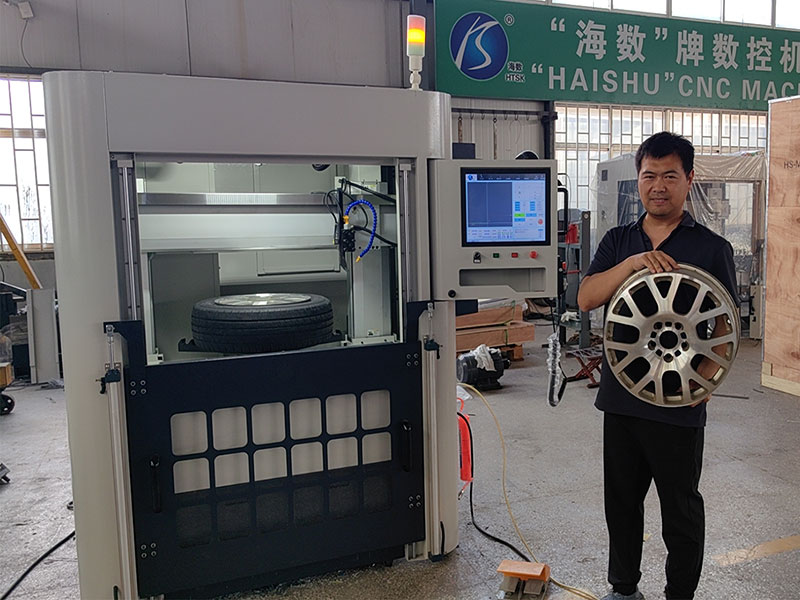

CNC on Wheels refers to the process of refurbishing or repairing the surfaces of automotive alloy wheels using CNC (Computer Numerical Control) lathe machining. This method has become the mainstream technology in wheel refurbishment, providing precise and efficient solutions for damaged or worn wheels. For customers new to this type of restoration, selecting a suitable wheel repair lathe can be challenging. In this article, we will introduce the wheel repair machines from Taian Haishu as a reliable reference.

2. What Are the Key Benefits of CNC on Wheels?

2.1 Precision and Efficiency

The primary advantage of CNC on Wheels is its precision. CNC machines, including diamond-cut wheel lathes, utilize advanced technology to ensure that each wheel is refurbished to exact specifications. This level of precision minimizes the risk of errors that can occur with manual processes.

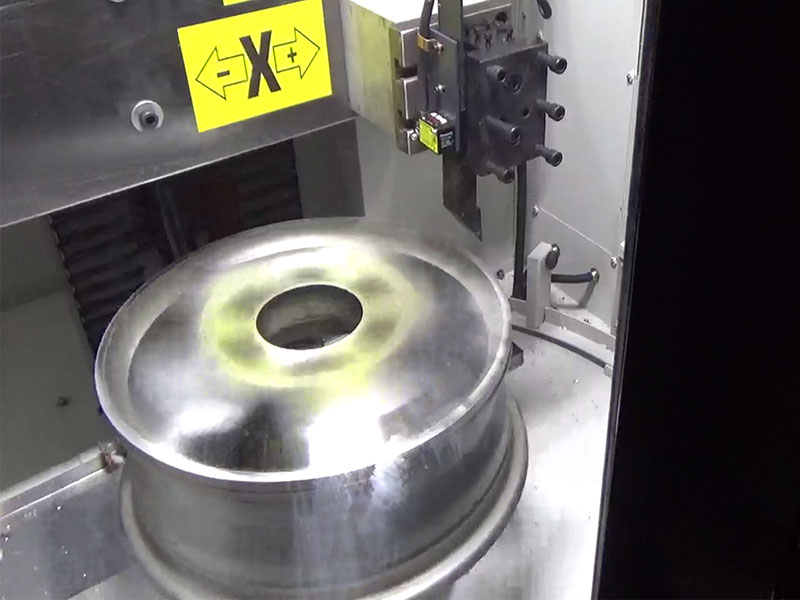

2.2 Time-Saving Detection Methods

One of the current mainstream detection methods for CNC on Wheels is laser detection, which completes a scan in just 15 seconds. This speed significantly outperforms traditional probe detection, which typically takes around 10 minutes.

Advantages of Laser Detection

- Speed: Quick scanning reduces downtime.

- Safety: Minimizes collision accidents involving the probe.

- Cost-Effective: Taian Haishu offers this detection method free of charge, along with probe and tooltip detection.

2.3 Types of Detection Methods

Taian Haishu has developed three types of detection functions:

- Laser Detection: Fast and efficient, ideal for most wheel surfaces.

- Probe Detection: Slower but useful for more detailed assessments.

- Tool Tip Detection: The most precise method, suitable for larger wheel surfaces with significant undulations.

3. How Do Tool Holders Impact CNC on Wheels?

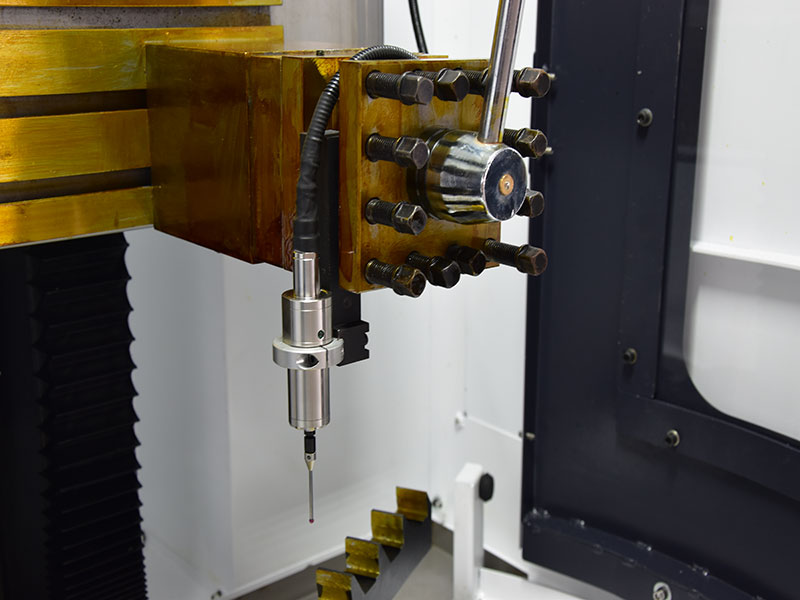

3.1 Selection of Tool Holders

The choice of tool holder is crucial when considering CNC on Wheels. An effective tool holder can enhance efficiency and reduce the risk of mechanical failures.

3.2 Types of Tool Holders

- Straight-Line Tool Holder:

- Allows for direct switching between the probe and cutting tools.

- Saves time and reduces mechanical issues.

- Low maintenance and replacement costs.

- Four-Station Mechanical Tool Holder:

- Allows manual rotation to select cutting angles.

- Higher replacement costs and potential for wire entanglement.

- Electric Automatic Tool Holder:

- Automatically rotates and selects the cutting tool.

- Most advanced and expensive option, with high repair costs if damaged.

4. Why Is Optimization Important in CNC on Wheels?

4.1 Wheel Curve Optimization

Even after detection, optimization of the wheel curve is necessary in the CNC on Wheels process. Taian Haishu provides both automatic and manual optimization options to cater to different wheel surface complexities.

4.2 Automatic vs. Manual Optimization

- Automatic Optimization:

- Suitable for smooth wheel surfaces.

- One-click functionality simplifies path optimization.

- Manual Optimization:

- Ideal for complex surfaces.

- Allows technicians to manually select points on the detected surface for precise adjustments.

5. How Does CNC Programming Work in CNC on Wheels?

5.1 Simplifying CNC Programming

Complex CNC programming has historically been a concern for customers involved in CNC on Wheels. However, Taian Haishu has developed a one-click output for CNC programs.

5.2 Advantages of One-Click CNC Programming

- Reduced Labor Costs: Eliminates the need for professional CNC programmers.

- User-Friendly: Novice operators can achieve advanced programming skills.

- Error Reduction: Minimizes programming mistakes, facilitating precise machining.

6. What Is the Importance of Tool Alignment in CNC on Wheels?

6.1 Achieving Precision Through Tool Alignment

Achieving precision in wheel repair and accurate tool alignment is crucial in the CNC on Wheels process. Manual tool alignment can lead to deviations, and even precise CNC programming may result in incorrect machining.

6.2 One-Click Tool Alignment

Taian Haishu’s one-click tool alignment feature sets the starting points for the X and Z axes of the machining process, ensuring accurate and consistent results.

7. How to Choose the Right Wheel Repair Machine?

7.1 Factors to Consider

When selecting a wheel repair machine, consider the following factors:

- Detection Methods: Evaluate the types of detection available and their effectiveness.

- Tool Holder Options: Determine the best tool holder type for your specific needs.

- Optimization Features: Look for machines that offer both automatic and manual optimization.

- CNC Programming Ease: Choose machines that simplify the programming process.

- Budget: Consider the price of rim straightening machines and overall operational costs.

7.2 Conclusion

In summary, understanding CNC on Wheels and its various components is essential for making informed decisions about wheel refurbishment. Taian Haishu offers a range of advanced machines tailored to meet your needs, including CNC alloy wheel repair and wheel CNC machines.

If you wish to learn more about the features of Taian Haishu’s wheel repair machines, we invite you to contact us by phone or email. We also welcome you to visit our factory, where we aim to provide professional services that enhance your understanding and appreciation of our wheel repair capabilities. Investing in the right wheel repair lathe can significantly improve your operations and customer satisfaction.