1. What Is CNC Rim Repair?

CNC rim repair is the sophisticated process of refurbishing and repairing scratches, dents, and missing parts on car rims using CNC (Computer Numerical Control) technology. By employing CNC lathes and wheel repair machines,(Rad reparatur maschine) damaged rims can be restored to their original factory specifications, preserving the vehicle’s value and minimizing losses for the owner. However, selecting the most suitable CNC rim repair service can be challenging for customers. In this article, we will introduce Tai’an Haishu’s rim repair lathes, specifically the CK6160Q and CKL22Q CNC rim repair machines.

2. What Are the Key Features of CNC Rim Repair Machines?

2.1 CK6160Q CNC Rim Repair Lathe

The CK6160Q is a horizontal-structured alloy rim repair lathe, designed for efficient and effective rim refurbishment. The horizontal structure means that the spindle runs parallel to the ground, allowing the chuck to hold the rim vertically. This configuration is ideal for various rim shapes and sizes.

2.2 Specialized Repair Systems

The CK6160Q features a specialized repair system equipped with advanced detection technologies:

- Laser Detection: Suitable for rims with smooth surfaces, this method completes detection in just 15 seconds, making it quick and user-friendly.

- Probe Detection: Ideal for rims with significant surface irregularities, this method takes about 5-8 minutes but provides precise feedback through contact probing.

- Knife-Edge Detection: This is the most accurate method, specifically designed for deep-lipped alloy rims. It generates precise trajectories using knife-edge contact.

These detection methods allow customers to select the most appropriate option based on the condition of their car rims.

3. How Does the Tool Holder System Work in CNC Rim Repair?

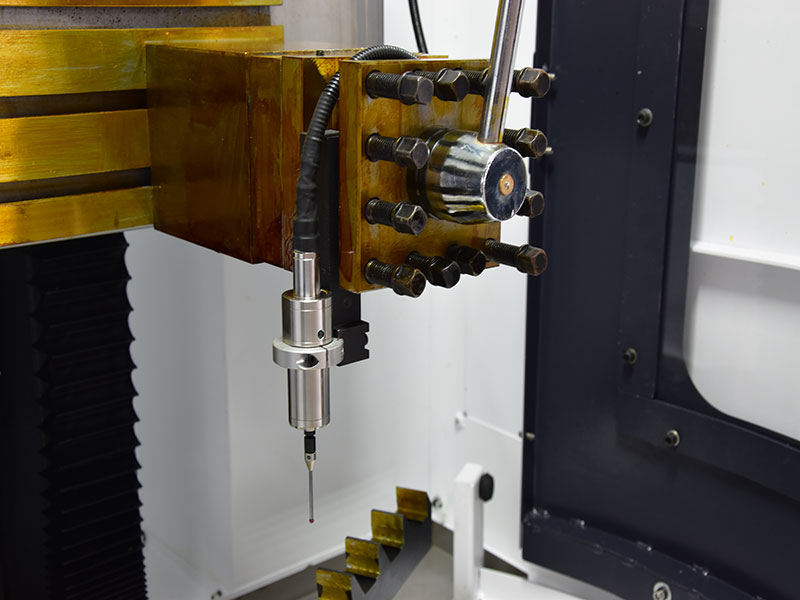

3.1 Types of Tool Holders

The CK6160Q comes with three types of tool holders, each designed for different applications:

- Straight Tool Holder: This holder allows for direct installation of cutting tools and laser probes, saving time and reducing mechanical failure risks. Replacement is straightforward if damaged.

- Manual Tool Holder: This holder allows for manual rotation to select between probes and cutting tools. It can adjust the knife edge angle for better surface repair but may be prone to wire entanglement.

- Electric Tool Holder: Automatically rotates without wire entanglement, but it is more expensive and requires professional maintenance.

Each tool holder has its own advantages and disadvantages, allowing users to choose based on their specific needs.

4. What Optimization Features Are Available in CNC Rim Repair?

4.1 Automatic and Manual Optimization

Tai’an Haishu’s optimization features stand out in the CNC rim repair process. Both automatic and manual optimization options are available:

- Automatic Optimization: This feature is designed for smooth rim curves. Users can click repeatedly for automatic optimization until the desired machining path is achieved.

- Manual Optimization: This option is for curved rim surfaces, allowing manual adjustments to refine the CNC machining path. With practice, operators can effectively use this feature.

4.2 User-Friendly CNC Program Generation

After optimizing the path, generating the CNC program is as simple as pressing a button. This user-friendly one-click function edits an existing CNC program, making it accessible even for those unfamiliar with CNC programming. Tai’an Haishu provides training videos and technical guidance, enabling customers to complete professional CNC operations within 30 minutes.

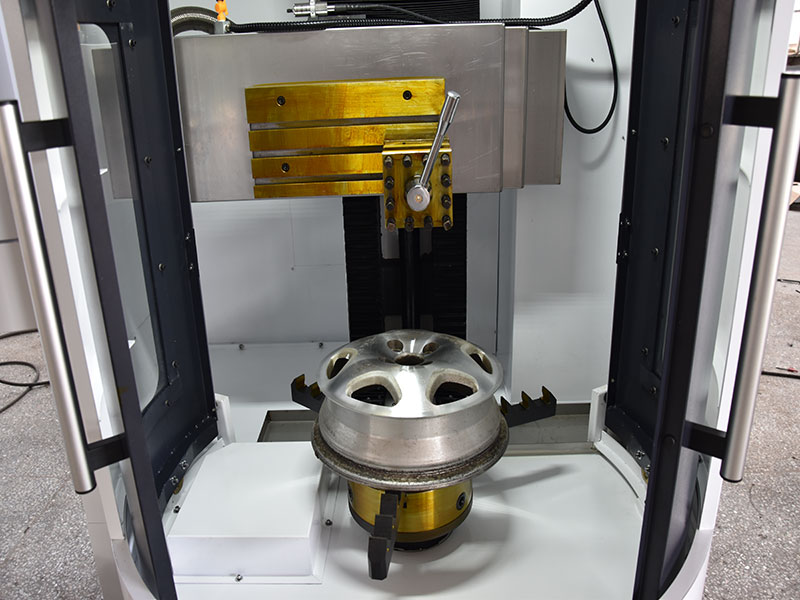

5. What Is the CKL22Q CNC Rim Repair Machine?

5.1 Vertical Structure for Enhanced Stability

The CKL22Q is a vertical-structured rim repair lathe, where the spindle is positioned perpendicular to the ground. This unique design allows rims to be placed flat on a specially extended clamp, effectively eliminating vibrations caused by gravity.

5.2 Precision and Speed

This CNC rim repair machine utilizes linear guides for rapid movement and high machining precision, making it especially suitable for aluminum alloy car rims. The finish achieved is smoother, and if the guide rails are damaged, they can be quickly replaced, restoring the machine’s initial precision.

5.3 Mirror Finishing Capability

With the CKL22Q, customers can achieve the best results for mirror finishing and rim silk processing on car rim surfaces. These capabilities make it an ideal choice for those looking to enhance the aesthetic appeal of their wheels.

6. How Do CNC Rim Repair Machines Compare to Other Equipment?

6.1 Comprehensive Solutions from Tai’an Haishu

As a professional manufacturer of rim repair machinery, Tai’an Haishu offers a wide range of equipment beyond CNC rim repair machines. Their product line includes:

- Wheel Repair Lathes:(Máy sửa chữa bánh xe) Specialized machines for effective wheel refurbishment.

- Wheel CNC Machines: (Tekerlek tamir makinesi)Advanced CNC systems designed for various wheel machining tasks.

- Diamond Cut Wheel Lathes:(آلة إصلاح العجلات) Machines specifically for creating high-quality diamond-cut finishes on rims.

These products provide integrated solutions for customers, ensuring that all aspects of wheel repair and refurbishment are covered.

7. How Can You Get Started with CNC Rim Repair?

7.1 Contact Tai’an Haishu for More Information

If you’re interested in learning more about CNC rim repair and the machines offered by Tai’an Haishu, please don’t hesitate to contact us. Our team is ready to provide detailed information and support to help you make an informed decision.

7.2 Visit Our Factory

We encourage customers to visit our factory to see our capabilities firsthand. This visit will allow you to gain a deeper understanding of our products and the technologies we employ in CNC rim repair.

8. Conclusion

In summary, CNC rim repair is an essential service for restoring the functionality and appearance of car rims. With machines like the CK6160Q and CKL22Q from Tai’an Haishu, customers can benefit from advanced detection systems, user-friendly programming, and high-precision machining capabilities. Whether you need a wheel repair lathe (Máquina de reparo de rodas), wheel CNC machine, or diamond cut wheel lathe, Tai’an Haishu offers comprehensive solutions to meet your needs. For more information, please reach out to us or visit our factory.