What is CNC Wheel Rim Repair in the UK?

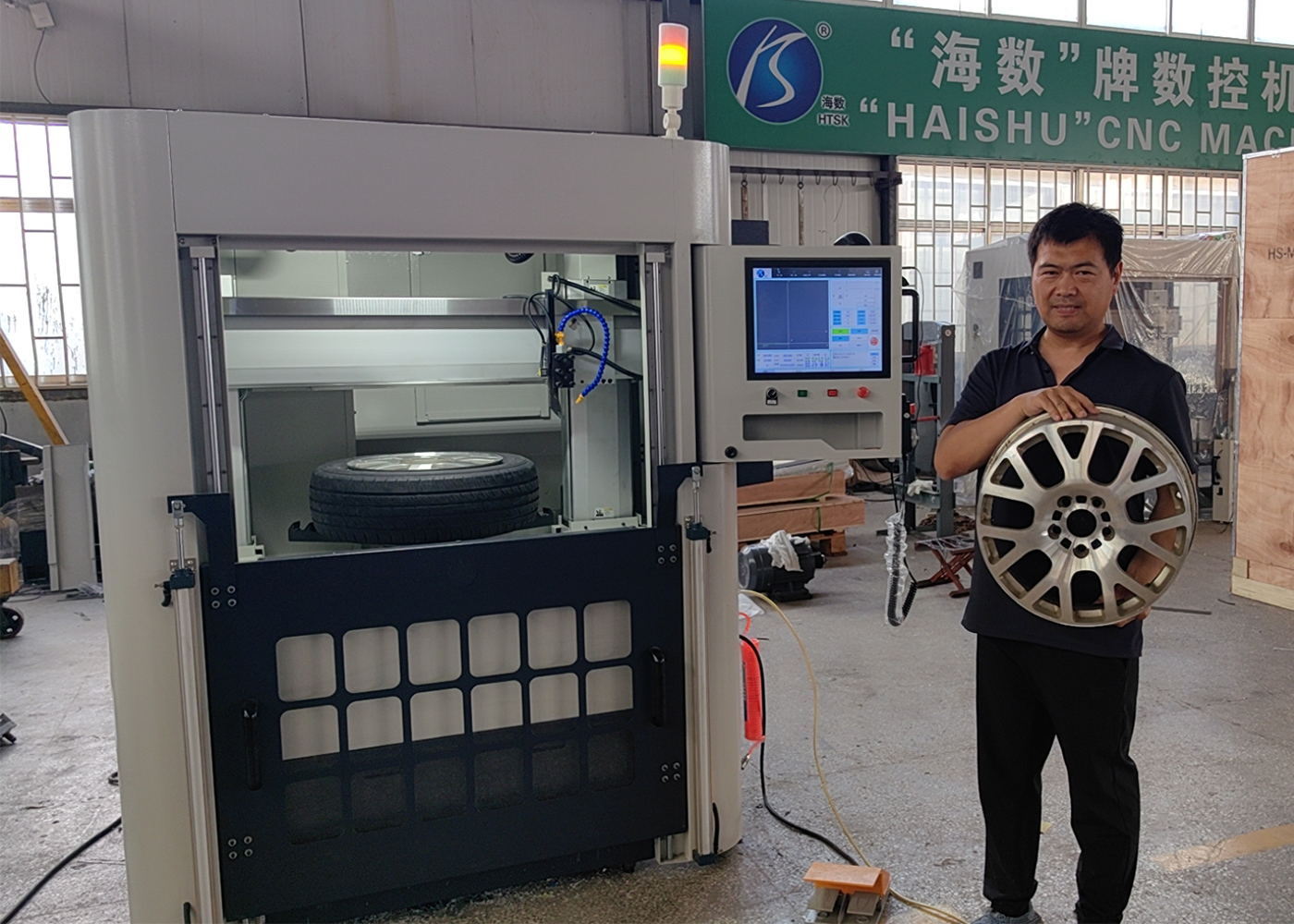

CNC Wheel Rim Repair in the UK refers to the process of using CNC lathes to cut and repair automotive wheel rims. Unlike the standard CNC lathe system, a specialized wheel repair machine system is used for CNC operations and machining. In this article, we will introduce HAISHU Company’s CNC rim repair process, specifically tailored to the UK market. We welcome your feedback and suggestions, which we will use to update and customize our products according to your needs.

How Does the CNC System Enhance CNC Wheel Rim Repair in the UK?

The most crucial component of CNC Wheel Rim Repair in the UK is the CNC system of the wheel repair lathe. Unlike standard CNC systems, HAISHU’s developed CNC system supports both laser probes and mechanical contact probes. Additionally, it incorporates a more precise tooltip detection method, achieving comprehensive coverage on different wheel hub surfaces. Traditional CNC systems do not support multiple detection methods and rely on manually recording coordinates with a pen, followed by manual programming to create CNC programs. This requires a high level of technical skill from operators, who must have a solid foundation in CNC programming and operation. The learning curve is steep, and the cost is high for wheel CNC machine customers.

What Makes HAISHU’s CNC System Ideal for CNC Wheel Rim Repair in the UK?

HAISHU’s CNC system for CNC Wheel Rim Repair in the UK is designed to be user-friendly and efficient. Our CNC system requires no prior CNC programming knowledge from the operator and can be fully mastered in just 30 minutes. How is this possible? We use laser detection, which reduces detection time to just 15 seconds. You can also use a contact probe, though the detection time is longer. The operation steps are the same: use MPG to move to the start and end points of the wheel hub and set these points with a one-click function to detect from the start to the end point automatically.

How Does HAISHU Optimize the CNC Wheel Rim Repair Process in the UK?

After the automatic detection is complete, our system automatically displays the detected curve path. To facilitate customer path optimization, we have developed an internal optimization function within the CNC system, eliminating the need for external optimization software. We have also set up both manual and automatic optimization functions, allowing for one-click optimization, and saving a substantial amount of time in path analysis and optimization.

What Are the Programming Requirements for CNC Wheel Rim Repair in the UK?

Once the curve path is optimized, the CNC program output settings can be directly configured without the need for complex manual CNC programming. This means that workers can have zero CNC foundational requirements. Another highlight is our one-click tool setting function, which does not require manual coordinate input to set the tool’s machining starting point. As long as the tooltip position aligns with the detection starting point, it is set. We even provide stickers for marking to ensure that the detection and machining start points are in the same location.

What Additional Features Enhance CNC Wheel Rim Repair in the UK?

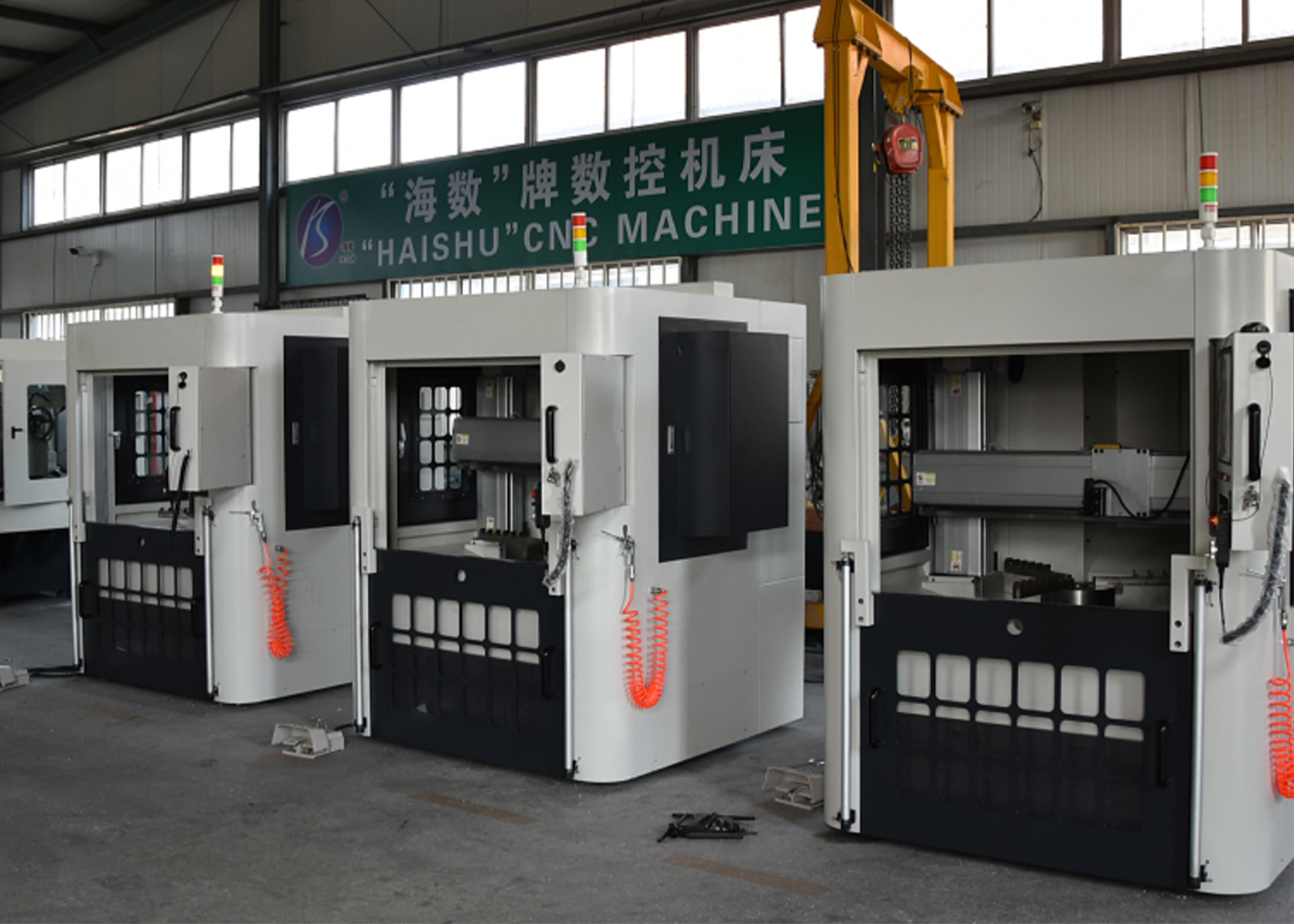

After machining is complete, we provide an air-cleaning gun. During machining, we also employ air cooling to cool the tool while blowing away aluminum chips, preventing debris from scratching the finished wheel hub surface. For wheel hub repair, we have developed both horizontal and vertical wheel repair lathes, using cast iron guides and linear guides. In the vertical structure, we have developed single-column and double-column modes to increase machining rigidity.

Why Choose HAISHU for CNC Wheel Rim Repair in the UK?

If you require a CNC wheel repair lathe or have alloy wheel repair needs, please contact us. We provide professional sales and service systems. We also offer ODM services, allowing you to have your own branded wheel repair lathe. We look forward to further business discussions with you.

Conclusion: The Future of CNC Wheel Rim Repair in the UK

In conclusion, CNC Wheel Rim Repair in the UK has been revolutionized by HAISHU’s innovative approach. Our CNC system, designed for ease of use and efficiency, eliminates the need for extensive CNC programming knowledge and reduces detection time significantly. The internal optimization functions and one-click tool settings make the process straightforward, even for operators with minimal experience.

Our advanced features, such as air cooling and cleaning guns, ensure that the final product is free from debris and scratches, maintaining a high-quality finish. The development of both horizontal and vertical wheel repair lathes, with various structural options, provides flexibility to meet different repair needs.

By choosing HAISHU for your wheel repair needs, you are investing in a system that offers precision, efficiency, and ease of use. Our commitment to innovation and customer satisfaction ensures that our products will meet and exceed your expectations. Whether you are a repair shop looking to enhance your services or a business seeking custom-branded equipment, HAISHU provides the solutions you need.

Contact us today to learn more about our CNC wheel repair lathes and alloy wheel repair services. We are here to support you with professional sales and service systems, ensuring that your business remains at the forefront of the industry. With HAISHU, the future of CNC wheel repair in the UK looks brighter than ever.